How to Troubleshoot and Repair a Noisy Washer

A washer makes many different noises while it runs—this is normal! But when it starts making new or unusual sounds, it may be time to repair or replace some parts. We’re here to help you determine what types of sounds are normal, and which sounds might indicate a problem. There are some questions that may help you narrow down the source:

- What does the noise sound like? (Is it thumping? Clunking? Grinding? Screeching? Banging? Rubbing? Rattling?)

- How long does the noise last?

- Is the noise continuous or only during certain cycles?

- Is it a front-load or top-load washing machine?

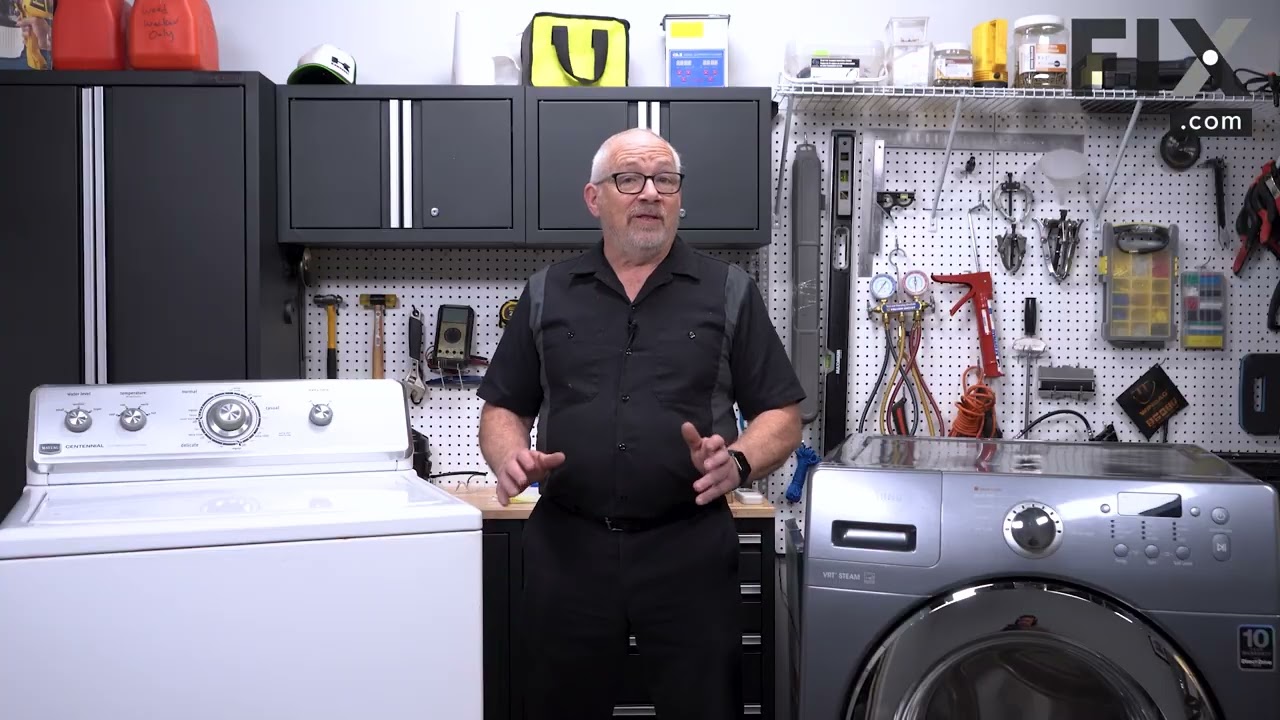

Use this following video to identify which sound your washer is making:

Sometimes the solution is as simple as removing extra items from your load of laundry. Other noises might require you to take apart the machine to figure it out. With our repair guides, 3D renderings, sounds clips, and instructional videos, we’ll help you determine what’s causing the noise in your washer and get it fixed.

Inspect These Common Issues First

Sometimes the solution is as simple as removing extra items from your load of laundry. Other noises might require you to take apart the machine to figure it out. With our repair guides, 3D renderings, sounds clips, and instructional videos, we’ll help you determine what’s causing the noise in your washer and get it fixed.

FIX TIP

Is There a Fault Code?

Depending on your washer model, there may be a fault code or flashing light displayed. If there is a fault code showing up, this is the first item you should inspect. Your user manual will be able to tell you what the code or light means. If a part has failed, this can help point you in the right direction.

Did an Object Get Caught Somewhere in the Washer?

If the washing machine is making noise during the spin cycle, especially a rubbing, clanking, or scratching sound, something may have gotten caught in the washer’s filter or the rubber seal, or is spinning in the drum. Some common items are socks, buttons, coins, and bra wires.

- Check the Drum

Start by checking for loose items in the drum, since that would be obvious.

- Check the Rubber Seal

Next, check underneath the rubber seal.

- In Between the Tub and the Drum

It is possible that an item may have gotten beyond the rubber seal and is in between the plastic tub and the washer drum. This can lead to more problems, such as puncturing the machine and causing damage that is irreversible and could possibly lead to a flood.

Check out this video on how to remove stuck objects in your washer:

Is Your Washer Unevenly Loaded or Overloaded?

A common user error is unevenly putting clothes into the washer or overloading the tub with too many items. In a top-load washer, uneven distribution of clothing in the tub causes the inner tub to spin unevenly, causing it to come in contact with the outer tub, resulting in a loud/unusual sound. One way to avoid this is to not overload the washer with heavy items, such as towels, rugs, and curtains, which absorb a lot of water, leading to an unbalanced load. Front-load machines will run out of balance with only a few articles in them, so throw some additional clothes or a couple of towels in with those single or couple items you need done right away.

Check out this video on how to properly load a washer:

Is Your Washer Level?

A washing machine that is not level with the floor may cause excessive vibration and could even damage the floors or walls that surround it. You want to ensure that all four legs are solid to the floor. If you apply any downward pressure in any corner of the washer, it should not rock or tip in any direction. Weak flooring can also cause your machine to not sit level, and the excessive shaking of the washer can further weaken the floor.

If you suspect that your washer is not level, check out our video on how to level your washer:

Are There Marks or Stains on Your Laundry After Washing?

If your laundry is coming out of the wash with new stains or markings, it can be an indication that certain parts are starting to fail or wear out. Once these parts fail, that’s when the different noises start happening.

When a transmission’s seal wears out, water gets into the gearcase and allows for oil or greased to be pushed up into the tub. Once that oil or grease is in the tub, the water picks it up and deposits it on the laundry. Typically, when water gets past a seal, the water will remove the lubrication from a bearing and it will start to squeak or screech. If this continues, the lack of lubrication will wear the bearings, eventually causing them to fail.

Another situation that will leave marks on clothes is when a washer is overloaded with clothes. This causes the laundry to be pushed up and rub the underside of the tub ring on top-load washers. This can cause marks on the clothes and will wear and roughen the underside of the tub ring. In front-load washers, an overloaded tub can cause small items like socks to be pushed between the inner basket and the door seal/gasket. The article will be marked with streaks or even eventually rip or tear.

Sometimes it can be worthwhile checking the pockets or examining clothing articles such as work pants or coveralls for grease stains or oily rags in the pockets. These oils and lubricants can easily transfer in wash water, especially in warm to hot washes.

Normal Sounds You Might Hear from a Washer

Humming or Whirling

A humming or whirling sound in a top-load washer is a normal sound during operation. The motor creates this sound during agitation/wash or spin cycles. This sound may occur as an intermittent noise that occurs as the motor turns the washer basket back and forth. This sound can also occur during the spin cycle when the motor is revving up to turn the washer basket at a faster speed. During the drain cycle, the pump runs continuously and may make a humming noise, which becomes more evident as the water drains.

Waterfall

This occurs during the water fill cycle when water is being added to the basket and the basket slowly spins to distribute the water equally over the garments.

Clicking

At the beginning of a cycle, this clicking sound is likely the sound of the lid locking.

Clunking

For some machines, a clunking sound is normal as it moves from one cycle to another (agitate to spin, for example). Clunking noises that are present outside of the normal functioning of the cycles should be investigated.

Electric Pulse or Buzzing

Some washers have a drive system that uses gears. This sound will occur when the motor is rotating back and forth to agitate the laundry.

Slurping or Gurgling

At the end of the drain cycle, this sound will occur due to air and water being pumped out.

Unusual Noises from a Washer and What to Inspect

The following sounds are commonly reported with noisy washer symptoms. Further details on specific parts and repair instructions can be found below this section.

Thumping

A thumping noise is most likely due to an unbalanced load, an unlevel machine, or the flooring under the washer not being suitable. Balancing the load and leveling the machine are easy fixes (see videos above), but reinforcing floors or relocating your washer may be a bigger repair.

Clunking

An abnormal clunking noise could be caused by a variety of parts. First, check that there are no loose parts or items in the tub. Either secure these parts or remove the objects. The next parts to check would be the spider-arm to see if it’s broken, any worn or loose belts, any worn or loose pulleys, the transmission, and the drive coupling to see if it’s worn (the machine will make a clunk if the motor doesn’t pause between agitate and spin cycles).

Grinding

A grinding noise can occur when two parts are rubbing together, either because they don’t have proper lubrication or because they have worn out and are now in contact. The parts you should inspect are the pump (is the impeller broken or in contact with an object?), the agitator (worn dogs or agitator itself), a faulty control board (causing the machine to not shift from agitate to spin), and if the spider- arm has broken.

Screeching

A screeching noise can indicate that the following parts have become loose or worn and should be replaced: a loose drive belt, a worn clutch, and dry or worn bearings.

Banging

A banging sound can indicate that your wash tub is not properly supported or centered in the machine. This can cause it to bang against the outer tub. You should check for and inspect the following areas if you hear a banging noise: Is the load out of balance? This can cause the tub to bang up against the machine. Is the washer level with the floor? Have the springs, pads, straps, or shocks worn out? Does your washer have a counterweight? If it is broken, your tub won’t be centered (this is a difficult repair that may be best left for a qualified service technician).

Is the suspension broken or worn? If the banging noise is a result of a broken or worn suspension, you may also notice that your washer shakes or moves while it is running. If you are experiencing all these symptoms, visit our repair page for Washer Is Shaking and Moving to help correct this problem.

Rubbing

A rubbing noise is likely caused by an item caught between the tubs, or an overfilled machine. Check if there is material stuck between the inner and the outer tub by inspecting the seals and the gasket on a front-load washer. If you have a top-load washer, ensure that you didn’t overfill the machine. This can cause the laundry to rub against the tub ring.

If you find excessive black powder, the snubber ring may need to be replaced. This is a difficult repair that may be best left for a qualified service technician.

Rattling

A rattling noise can occur when something is loose, or when a foreign object is stuck in the machine. If you are hearing a rattling noise, you should check to ensure that the washer is level. Then attach any loose brackets or components. If there are no loose parts, check the pump housing for foreign objects that may be stuck, and remove them.

Common Parts You May Need to Replace

The parts listed below are the most common causes of a noisy washer. More information such as part descriptions, 3D renderings, sound clips, and installation instructions are available on the individual part pages.

- Drain Pump and Pump Motor If you are hearing a loud buzzing noise during or after the spin cycle, there may be a blockage in the drain pump, or the pump motor may have seized. If this happens, you’ll also have water left in the tub after the cycle ends.

- Drive Belt If a squealing or screeching noise is coming from your washer, you likely have a worn-out belt. This sound will often be accompanied by a burning smell as well, due to the excess friction occurring.

- Direct Drive Motor Coupling The direct drive motor coupling is used to transfer power from the motor to the transmission. A vibrating noise from your washer may indicate that a coupling has worn out.

- Shock Absorbers Is your front-load washer making a loud banging noise while running the spin cycle? The shock absorbers or struts may have given out.

- Tub Dampening Straps If you’re hearing a continuous banging noise while your washer is running, there may be an issue with your tub dampening straps. When these fail, it causes your wash tub to hit against the cabinet.

- Drive Motor If you hear a buzzing or humming sound from your washer when the motor starts, you’ll want to get out the multimeter to inspect it. You may also notice a burning smell if your drive motor is failing.

- Pulleys (Drive Motor, Transmission, and Pump) The pulley works with the belt to spin the tub in your washer. A dirty or damaged pulley can result in a squealing or thumping sound when the washer is running.

- Pump Belt Some models of washers will have a pump belt to assist with draining. Signs that the belt is failing are a squealing or screeching noise along with the smell of burning rubber.

- Tub Bearings The tub bearings help spin and support your washer’s tub. If the lubrication on the bearings is gone, they will start to squeak. If the bearings are worn out, you’ll hear a grinding or rumbling noise.

- Agitator Directional Cogs/Dogs Agitator directional cogs are used to rotate the top half of a dual action agitator system in a top-load washer. If these cogs wear out, you may hear a crunching or grinding noise.

- Clutch Assembly The clutch assembly connects the washer tub to the transmission, which allows the basket to spin. If the clutch is failing, you’ll hear a squealing sound along with a burning smell and see brake dust under your machine.

- Spider Arm The spider arm is the support for the tub in your front-load washer. This part is susceptible to corrosion, and when it breaks it will make a very loud noise.

- Transmission A washer transmission can make a clunky noise when not engaging properly with other components. This sound will usually happen when switching from agitate to a spin cycle.

- Snubber Ring A snubber ring sits under the tub of your top-load washer and is used to absorb vibrations. If you hear a grinding or vibration noise and your washer is shaking, you may need to replace this part.