How to Fix a Tub Bearing for a Washer That is Noisy and Leave Marks on Clothes

You will find tub bearings in both top-load and front-load washers. These bearings help the tub to spin, along with providing support. There are a couple of different sounds you may hear with tub bearings that can indicate how close they are to failing completely. A squeaking sound usually means they need to be lubricated, while a grinding or rumbling sound usually indicates that the bearing has worn out and will need to be replaced. Continue reading below to learn more about preventative maintenance for your tub bearings, and the next steps to take if they’re wearing out.

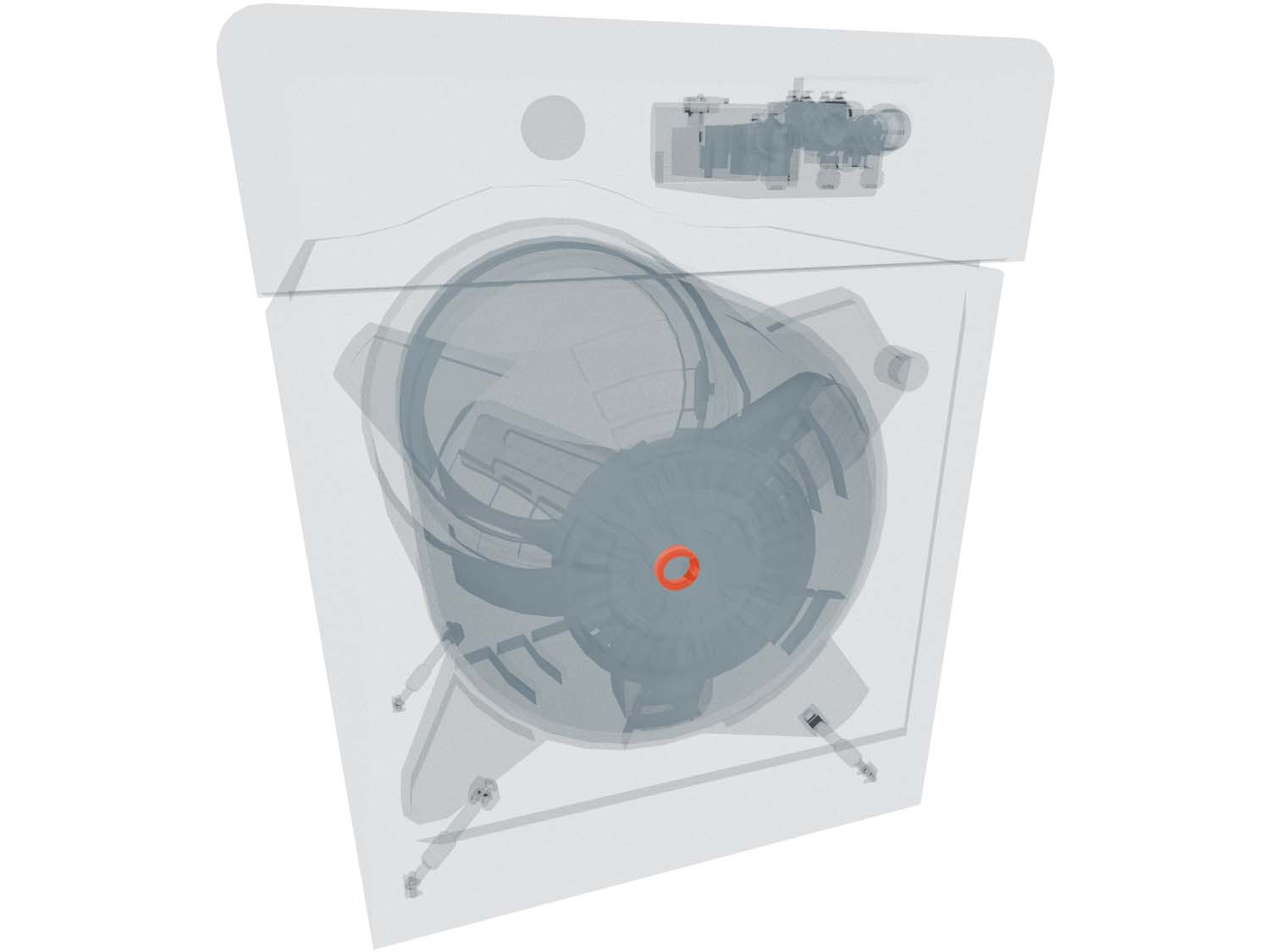

What are Tub Bearings and Where are they Located?

The tub bearings are meant to ensure free movement of the wash basket. In top-loading washers, there will typically be two bearings: one where the shaft connects to the clothes basket and one at the bottom or transmission input. The bearing is a circular metal part with small metal balls inside. These small metal balls sit in a track and move when the washer is spinning. If the bearing wears out, these small metal balls can start to fall out, causing the noise. Some washers use an oil-lubricated bearing and when the seal fails the lubrication can be washed away, causing them to squeak or squeal. In front-loading washers, both bearings will be supporting the clothes basket shaft at the back of the outer tub. In both sorts of washers, the bearings have a tub seal to keep them dry. But with laundry soap, heavy use, and time, the seal erodes and then the bearings can stop working.

General Location of the Tub Bearings in a Washer

What Type of Noise Can You Expect?

If your tub bearings have failed, you might hear a loud rumble or roar coming out of the washing machine when it is trying to spin. If the sound is more of a squeak than a grinding sound, this usually means that the bearing needs to be lubricated with mechanical grease. A grinding sound usually indicates that the bearing is damaged and needs to be replaced.

Signs That Your Seal and Bearings are Failing

An early indicator that your seals are failing (which will lead to your bearings failing) is grease marks on your laundry. When a transmission or tub seal wears out, water can enter the gearcase, allowing oil or grease to be pushed up into the tub, where water picks it up and deposits it on the clothes. Typically, when water gets past a seal, the water will remove the lubrication from a bearing, which causes it to squeak or screech.

Is it Safe to Use a Washer with Noisy Tub Bearings?

If you continue to use a washer with noisy tub bearings, you will cause more damage to your machine. This can include damage to the tub or the outer cabinet and will lead to a much more expensive repair.

How to Access, Remove, and Inspect the Tub Bearings in a Washing Machine

- Disconnect your washer from the power source.

- Remove the washer’s cabinet, remove the back panel, or tip back the machine and find the tub bearings. Depending on the style and model of washer you have, you may need to remove the inner tub, the wash basket, and/or the transmission to access the tub bearings.

- Inspect the tub bearings for any signs of cracking, rust, wear, water damage, or other sign that they have failed.

- If you find any of the above symptoms, you will need a replacement tub bearing.

- It is recommended that you replace your tub seal at the same time, especially if a bearing shows signs of rust or water damage. Inspect the shaft that the bearing supports for signs of wear as well.

How to Install a New Tub Bearings

This is a very large, involved, and advanced repair, and our experts have recommended that you watch our access/removal video above to get a sense of the amount of work involved. The process involves taking your washer completely apart piece by piece, and rebuilding it once the bearings are replaced. Watching the process in the video above will be a good opportunity to assess whether it is within your wheelhouse, or whether it would be something that would be better suited to hiring a technician to complete. Once that decision is on the table, so too is weighing up the cost of a technician completing this advanced repair, against the price of deciding to replace your entire machine. Whichever route makes you most comfortable, we want to help inform you so you can make the best decision for your washer and home.

Next: Troubleshooting the Agitator Directional Cogs/Dogs

Go To Main Page: Noisy & Marks Left on Clothes