How To Repair Chipper That Does Not Turn

- Rated as REALLY EASY

- 4 step by step videos

Drive Belt

The drive belt on your chipper shredder may be damaged or worn if the engine is running but the chipper does not turn. If the drive belt is broken or slipped out of place, the blades in the chipper will not be able to turn, even with the engine running. It is normal for the drive belt to incur some wear over time from regular use and will likely require replacing at some point during the life of the machine. To inspect the drive belt, remove the belt cover and reinstall it if necessary. If the belt is quite worn or broken, it should be replaced. Refer to your user manual for the proper replacement part number.

Idler Assembly

The chipper may not turn because the idler assembly needs adjusting. Located under the belt cover, the idler assembly functions to keep the right amount of tension on the drive belt, and also to stop the belt from slipping out of place. The drive belt is attached to the flywheel at one end, and to a drive shaft that spins the blade assembly at the other. The idler is a third pulley that is linked into the drive belt path. It keeps the belt from slipping out of place, so that it can run straight without wobbling, and also allows the operator to adjust the tension of the drive belt, should it become loose or need to be replaced. A broken bearing inside the idler can prevent it from rotating. This can stop the drive belt from moving at full speed, which will hinder the engines ability to turn the blades.

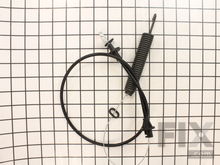

Engagement Cable

The engagement cable allows the blade assembly to start turning once the engine has reached its minimum speed to drive the chipper and shredder blades. The engine is equipped with this mechanism to allow the engine to start and idle without continuously being forced to turn the blade assembly. This keeps the engine from being overworked, and helps to extend it's lifespan. Normal operating RPM’s for the engine are 3200 – 3400 RPM. Once the engine has reached this speed, the spring-loaded engagement cable engages and allows the drive belt to turn the chipper blades. If the engagement cable breaks or is not adjusted properly, the blades will not turn. It is common for an engagement cable to wear over time. It can be replaced easily.

Drive Shaft

The driveshaft is attached to the blade assembly, and is responsible for spinning the blades in the same way that the crankshaft is responsible for spinning the flywheel. The flywheel and driveshaft are connected with the drive belt, which takes the spinning motion of the flywheel and crankshaft and transfers it to the driveshaft, causing it to rotate the blade assembly. A broken driveshaft can slow or stop the blade assembly from spinning altogether. The bearings inside of the driveshaft assembly can become worn or break, which will stop it from rotating. If your driveshaft is stopping the blade assembly from rotating, it may have to be repaired or replaced altogether.

More Repair Parts

Still not sure which part is broken? We can offer you custom troubleshooting help if you search with your model number.