How To Repair An Oven That Won't Turn On

- Rated as EASY

- 4518 repair stories

- 9 step by step videos

Fuses

With an oven that has internal fuses, a fuse can blow when there are problems with wiring or other components. First, unplug the range or oven, and then find the fuse that is blown. The fuses are usually labeled, so you can track down which circuit has a problem in its components and/or a short in its wiring that caused that particular fuse to blow. Don’t bother to change the fuse until you know the cause of the problem, and when you do change the fuse, make sure the new one is of the same rating as the original. You can use the same method if the blown fuse corresponds to a stovetop burner.

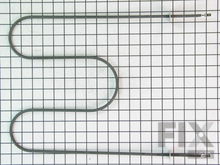

Broil Element

You’ll find the broil element on the roof of your oven. Because of the fact that it produces high heat to broil foods, it’s prone to blistering or separation, so check for that first. If there aren’t any visual signs of disrepair, unplug the oven and use a multi-meter to check for electrical continuity. To do this, take the back panel off the oven, find the terminals for the broil element, and while you’re there, check the wiring and terminals to see if they’ve overheated or gotten damaged. Should you find broken wiring or terminals, you’ll need to repair or replace them. If your check reveals no continuity for the element, simply replace it. If continuity was detected, then you may be entering the territory of the licensed electrician or appliance technician where live voltage checks need to be performed. There may be a problem with the thermostat for the oven, the electronic element, or the fuse, if your oven has fuses.

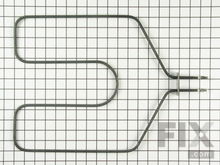

Bake Element

At the floor of the oven is the heating element for baking. If your oven is electric, the baking element will likely be providing 90% of the heat for baking, and the broiler will provide the rest, so your food cooks evenly. Therefore, the oven won’t heat up if the baking element is broken. First take a good look at the element itself to see if it is separated or blistered, in which case it would need replacing. But if it looks undamaged, try turning your oven on to bake for a minute before turning it off and carefully checking if the element’s gotten warm. If it is still cold, it’s time to unplug the stove, remove the back panel, and take a look at the wiring. Are the wires corroded or loose? Should you find broken wiring or terminals, you’ll need to repair or replace them. Check the bake element for continuity with a multi-meter. If there is no continuity, simply replace the element. But if instead your check of the bake element with a multi-meter reveals normal continuity, you are entering the territory of the licensed electrician or repairperson: live voltage will be involved. There may be a problem with the thermostat for the oven, the electronic element, or the fuse, if your oven has fuses.

Surface Burners

Depending on your appliance, you may have a coil burner, a solid burner, or a smooth-top range with a ribbon coil burner, but all burners are made of a heating wire that produces heat from electricity. No matter what type you have, start by unplugging the stove. And if the checks below don’t reveal the problem, try looking at the infinite switch. Coil Type Burner: Remove the non-functional burner element from the terminal block (or receptacle). Use a multi-meter to check for continuity. Check the end of the terminals to see if they’ve become corroded, or damaged by the heat. If any of these conditions constitute your problem, replace the whole terminal block at the same time as you replace the damaged coil. Solid Burners and Ribbon Coil Burners: Lift the main top to get access to the burner elements below. Remove the wires from the terminal of the non-functional burner, and make a visual check for damage as well as a multi-meter check for continuity.

Temperature Sensor

It’s possible that the reason your oven is cold is a fault in the temperature sensor, which regulates oven temperature in modern ovens, like a thermostat. It’s located on the back wall of the inside of your oven, near the top. On a newer oven, there may be a fault code displayed. Check your owner’s manual or the manufacturer website to find out the proper resistance of the temperature sensor, unplug the oven, and use a multi-meter to see if your sensor’s at the correct resistance.

Infinite Switch

When no heat’s coming from a particular element on a modern oven, the problem may lie at the infinite switch, which is responsible for sending power to the surface elements. So if the element itself and the terminal block and wires to that element are all good, unplug the stove and remove the back panel of the console to check the infinite switch at the control panel. Are there wires that have overheated? Or broken terminals to or from the infinite switch? Does a check with the multi-meter reveal that the contacts have continuity? If not, you can swap the infinite switch out for a new one. But if there’s nothing wrong with that infinite switch, you are entering the territory of the licensed electrician or repairperson: live voltage will be involved in testing the electricity level coming into the switch.

Electronic Control Board

If you have a newer stove that’s not restaurant-style, it’s likely that the oven is controlled by an electronic control board. It functions like the brain of the stove, managing the broil and bake functions of an electric range as well as the oven safety valve of a gas one. When power’s not flowing to the circuits for the igniter or elements, the output relay needs to be checked at the control board, by a trained professional because of the risk of electric shock. That repairperson can help you determine whether the control needs replacement due to a lack of voltage output.

Safety Valve

One possibility when your oven won’t heat up is a failure of the oven safety valve, otherwise known as the gas valve. This part, which doesn’t often break, ensures that gas only comes to the oven when the igniter is hot enough to light up the gas. The igniter that controls the oven safety valve sits right by the burner and if it does not glow when you turn the oven on, have a repairperson do a live voltage check to ensure there’s electricity flowing to that circuit. If there’s no electrical continuity in the terminals for the safety valve, use a multi-meter to see if the break in electrical flow is happening at the bi-metal in the valve.

Oven Burner Igniter

On a newer gas oven, the burners release and set fire to the gas via a device called the hot surface igniter. The ignitor is a very fragile thing, whether it’s the round or the flat type. It works like a chain reaction: turning on the oven sends electricity to the igniter, causing it to heat red-hot. This makes the two metals in the oven safety valve contort enough to open the valve and set the gas aflame. This chain reaction takes about 60 seconds in a working oven. And a persistently cold oven could be the result of any break along the chain. A burner that won’t light could be connected to an igniter with no power coming into its circuit. Have a repairperson check the circuit for electricity, since this is a live voltage check. If there is indeed power coming to the igniter, and it is open circuit, a multi-meter can be used to run a continuity check. It may be that, while the igniter is glowing, it’s still insufficiently hot to open the valve: this can be checked by your repairperson with an amp meter. A defective igniter can’t be repaired: replacement is the only option.

More Repair Parts

Still not sure which part is broken? We can offer you custom troubleshooting help if you search with your model number.