How To Repair An Aerator With A Noisy Engine

- Rated as REALLY EASY

- 5 step by step videos

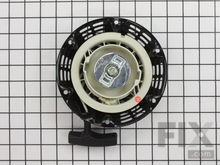

Starter Assembly

If your aerator engine is making an unusual amount of noise but running normally, the starter assembly may be loose or vibrating, causing excessive noise. The vibrations caused by the engine can loosen certain parts of the aerator so it is good to monitor it. Be sure to stop the engine before inspecting any parts. If the noise is coming from the top of the engine where the starter assembly is located, check the assembly for loose parts. Try tightening all screws and connections with a screwdriver to ensure that all components are tightly secured. Test the engine afterward to see if there is a decrease in the amount of noise.

Crankshaft Bearing

If the excessive noise is coming from the engine itself, it is possible that there is an issue with the crankshaft bearing due to lack of lubrication or wear to the bearings. The crankshaft itself can sometimes become bent or warped. If this happens, excessive vibration and noise can be created from within the engine. To inspect the crankshaft, the engine will have to be partially disassembled. If the crankshaft is warped or bent at all, it should be replaced before the engine is run again. Because the crankshaft spins at such high speeds, any slight change in its calibration can cause the engine create more noise than usual when running due to the excessive vibrations created by the unbalanced crankshaft.

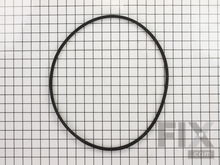

Belts

Stop using your aerator immediately if you detect the smell of burning rubber. This smell indicates that there is stress on the rubber belts causing them to melt while the engine is running. The belt assembly must be properly adjusted at all times. If the belts are too loose, they can slip off of the drive pulley. The friction created by the drive pulley spinning but not gripping the belt tightly enough can cause enough heat to melt the belt entirely. If the belts are too tightly fastened, they can heat up while rotating to the point of overheating which will cause the rubber in them to wear. In either of these cases, burning rubber indicates that the belts are not adjusted properly. The idler assembly should be inspected to ensure that the tightness of the belts is within a range that the machine is still safe to operate at. Overloading the machine will also cause the belts to slip and burn.

Engine

Engine timing refers to the alignment of the engines parts all performing their motions and rotations exactly when they should. If the engines timing is off, the valves that intake air and release exhaust will open for a moment during the engines compression and combustion strokes, causing the engine to run poorly, backfire or lose power. Engine timing can be thrown out of calibration from regular use and wear on these tight-fitting mechanical components. Some engines also have timing belts that can slip or break. A major incident involving the crankshaft can also throw off the engines timing, which will lead to excess noise.

Crankcase

The most likely cause of a noisy engine is lack of lubrication. The crankcase should be topped up with oil on a regular basis, and its oil level monitored if the machine is being used for a long period of time. The various moving components within the crankcase require oil to reduce friction and wear. If sufficient lubrication is not present, these parts will grind together, causing friction and creating noise. It is recommended to always keep your engine topped up with oil in order to maintain the health and good working order of all internal components.

More Repair Parts

Still not sure which part is broken? We can offer you custom troubleshooting help if you search with your model number.