Models

>

BA283

BA283 Maytag Washer

Jump to:

Find Part by Name

Keep searches simple, eg. "belt" or "pump".

Diagrams for BA283

Viewing 9 of 9Keep searches simple, eg. "belt" or "pump".

$200.68

This washing machine drain pump is intended for use with automatic washers that have been manufactured since 1958. The pump itself is made of plastic, though it does come with a metallic belt pulley.

In Stock

Order within the next 3 hrs and your part ships today!

$15.28

This foot pad is just over an inch in diameter. It is made entirely of rubber and is gray in color. This pad is intended for use with washers and some dryers.

In Stock

Order within the next 3 hrs and your part ships today!

$18.47

Sold Individually. This adjustable leveling leg comes with a stop nut.

In Stock

Order within the next 3 hrs and your part ships today!

In Stock

Order within the next 3 hrs and your part ships today!

$45.24

This damper pad kit is used for base support. It comes with three six inch damper pads, two little tubes of lubricant. NOTE: This part will need adhesive to stick it in place.

In Stock

Order within the next 3 hrs and your part ships today!

$57.98

This glide and spring kit contains two three inch springs, four one inch square glides, and two tubes springs. This kit replaces older style round roller glides.

In Stock

Order within the next 3 hrs and your part ships today!

In Stock

Order within the next 3 hrs and your part ships today!

In Stock

Order within the next 3 hrs and your part ships today!

In Stock

Order within the next 3 hrs and your part ships today!

In Stock

Order within the next 3 hrs and your part ships today!

In Stock

Order within the next 3 hrs and your part ships today!

$7.59

This timer knob spring is almost an inch and a half long, and is not quite an inch in diameter. It is made of metal and is used with the timer knobs of both washers and dryers.

In Stock

Order within the next 3 hrs and your part ships today!

Questions and Answers

We're sorry, but our Q&A experts are temporarily unavailable.

Please check back later if you still haven't found the answer you need.

Common Problems and Symptoms for BA283

Viewing 6 of 6Leaking

Fixed by these parts

How to fix it

Will not drain

Fixed by these parts

How to fix it

Burning smell

Fixed by these parts

How to fix it

Will not agitate

Fixed by these parts

How to fix it

Spins slowly

Fixed by these parts

How to fix it

Shaking and Moving

Fixed by these parts

How to fix it

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

- Customer:

- dominic from weirton, WV

- Parts Used:

- 205000

- Difficulty Level:

- A Bit Difficult

- Total Repair Time:

- 30 - 60 mins

- Tools:

- Nutdriver, Screw drivers

The belts were not staying tight enough to agitate properly.

Firstly, remove ac power from washer!

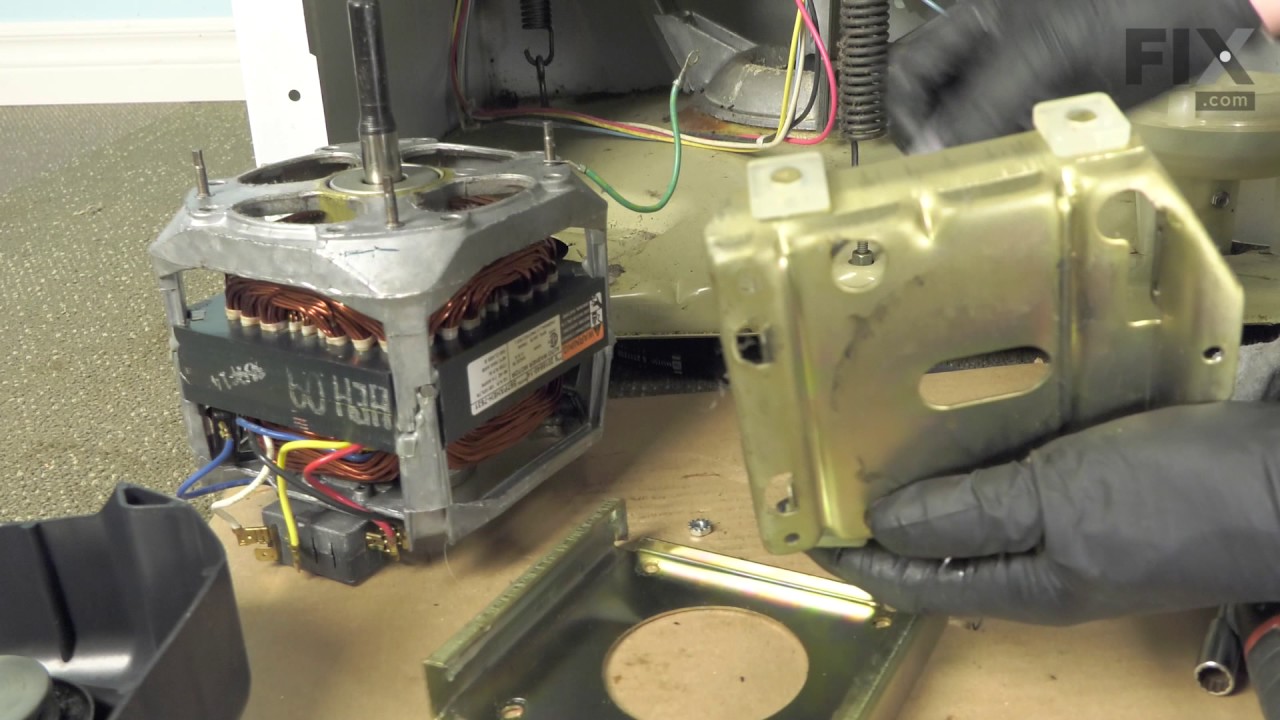

After removing the front panel of the washer (two philips screws), I loosened and removed the plastic motor cover and removed three hex head screws holding the motor. Have someone help you tilt the washer so you can remove the belts by "rolling" them off of the pullies (pump pully and motor pully ... Read more ). What I did was use a chemical degreaser to clean the motor base metal channel where the nylon sliders reside. After doing that and letting it dry, I removed the two old

springs. I ended up reinstalling the old springs because they were not stretched and I installed a new spring (total three) on the right side of the mount. A stiff metal rod with a hook on the end will help you install the springs. Squirt some of the included silicone lubricant on both sides of the motor mount channel and exercise the lube. Reinstall the motor and plastic cover over top of motor. Clean hands and clean belts while you have them out, reinstall belts and front cover and you're finished. My wife said it never ran better!

After removing the front panel of the washer (two philips screws), I loosened and removed the plastic motor cover and removed three hex head screws holding the motor. Have someone help you tilt the washer so you can remove the belts by "rolling" them off of the pullies (pump pully and motor pully ... Read more ). What I did was use a chemical degreaser to clean the motor base metal channel where the nylon sliders reside. After doing that and letting it dry, I removed the two old

springs. I ended up reinstalling the old springs because they were not stretched and I installed a new spring (total three) on the right side of the mount. A stiff metal rod with a hook on the end will help you install the springs. Squirt some of the included silicone lubricant on both sides of the motor mount channel and exercise the lube. Reinstall the motor and plastic cover over top of motor. Clean hands and clean belts while you have them out, reinstall belts and front cover and you're finished. My wife said it never ran better!

Read less

Was this instruction helpful to you?

Thank you for voting!

- Customer:

- John from Fort Lauderdale, FL

- Parts Used:

- WP6-2022030

- Difficulty Level:

- Really Easy

- Total Repair Time:

- 15 - 30 mins

- Tools:

- Nutdriver, Screw drivers

Water was not being removed from the wash tub after the spin cycle

I loosened three screws to relieve the belt tension and removed the belt from the pump drive pulley. After removing the water from the wash tub I removed the intake and output hoses from the pump. I next removed the mounting screws and removed the pump. I attached the new pump loosely and re-attached the belt. I moved the pump to tighten

... Read more

the belt tension and tightened the mounting screws. I re-attached the hoses, filled with water, checked for leaks and replaced the front panel.

Read less

Was this instruction helpful to you?

Thank you for voting!

- Customer:

- Robert from Menomonee Falls, WI

- Parts Used:

- WP6-2008160

- Difficulty Level:

- A Bit Difficult

- Total Repair Time:

- 30 - 60 mins

- Tools:

- Wrench (Adjustable)

The water didn't pump out during the spin cycle

I took out the two screws in the bottom front panel of the washer, and rotated the front panel from the bottom away from the machine until the top or the panel was released from the machine frame. I then tilted the washer back to get access to the bottom of the machine. The pump pulley had split in half, and the bottom half fell off the d

... Read more

rive motor shaft. The only problem I had was breaking free the set screw that holds the pulley to the drive motor shaft. I used a long arm Allen wrench and an adjustable "Cresent" wrench to apply enough force to break the set screw loose. Iclamped the upper transmission belts tightly to keep the motor shaft from turning while I loosened the set screw.

Read less

Was this instruction helpful to you?

Thank you for voting!