Models

>

MLE19PDAGW

MLE19PDAGW Maytag Washer Dryer Combo

Jump to:

Find Part by Name

Keep searches simple, eg. "belt" or "pump".

Diagrams for MLE19PDAGW

Viewing 16 of 16Keep searches simple, eg. "belt" or "pump".

$13.50

This OEM drum support roller kit contains the parts needed to replace one roller on your dryer. This kit includes one drum roller and two bearings. Most dryers use two drum rollers, and it is recommen...

In Stock

$14.70

This part is located on the front bulkhead of the dryer and helps the drum to rotate smoothly and quietly. If you notice a screeching or metal-on-metal noise while your appliance is operating, you may...

In Stock

$9.81

The roller shaft is also known as a support roller shaft or a drum roller axle. It is a part in your dryer that the drum rollers spin on, helping your dryer to tumble. If your appliance is noisy while...

In Stock

If your dryer is noisy while operating, or will not tumble at all, there may be an issue with the drum belt. Over time, the rubber can become brittle and snap, and the belt will need to be replaced. T...

In Stock

$7.88

Sometimes referred to as a retaining clip, the retaining ring is used to hold the drum support roller onto the shaft in your dryer. The clip may need to be replaced if you find that your dryer is nois...

In Stock

If your dryer is making excessive noise, or it will not tumble, there may be an issue with the idler pulley wheel. The idler pulley wheel is attached to the idler bracket and is used to secure the dry...

In Stock

$13.79

This roller shaft washer is just under an inch in diameter and is used for some of Whirlpool's brands of clothes dryers.Sold individually.

In Stock

$13.45

This idler pulley shaft washer is used with many clothes dryers. It is less than an inch long, and it is black in color.

In Stock

$15.93

This seal can be used for the front or rear drum. Adhesive is NOT included. For adhesive search: WPY055980

In Stock

In Stock

$46.00

This part moves the clothes around inside your dryer and helps to direct the flow of hot air during the drying cycle.

In Stock

$41.62

This part moves the clothes around inside your dryer and helps to direct the flow of hot air during the drying cycle.

NOTE: Screws are NOT included.

In Stock

Questions and Answers

We're sorry, but our Q&A experts are temporarily unavailable.

Please check back later if you still haven't found the answer you need.

Common Problems and Symptoms for MLE19PDAGW

Viewing 10 of 10Noisy

Fixed by these parts

How to fix it

Leaking

Fixed by these parts

How to fix it

Door won’t close

Fixed by these parts

How to fix it

Marks left on clothes

Fixed by these parts

How to fix it

Too hot

Fixed by these parts

How to fix it

Burning smell

Fixed by these parts

How to fix it

Will not agitate

Fixed by these parts

How to fix it

Spins slowly

Fixed by these parts

How to fix it

Drum Not Spinning

Fixed by these parts

How to fix it

Will not drain

Fixed by these parts

How to fix it

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

noisy rollers, broken latch

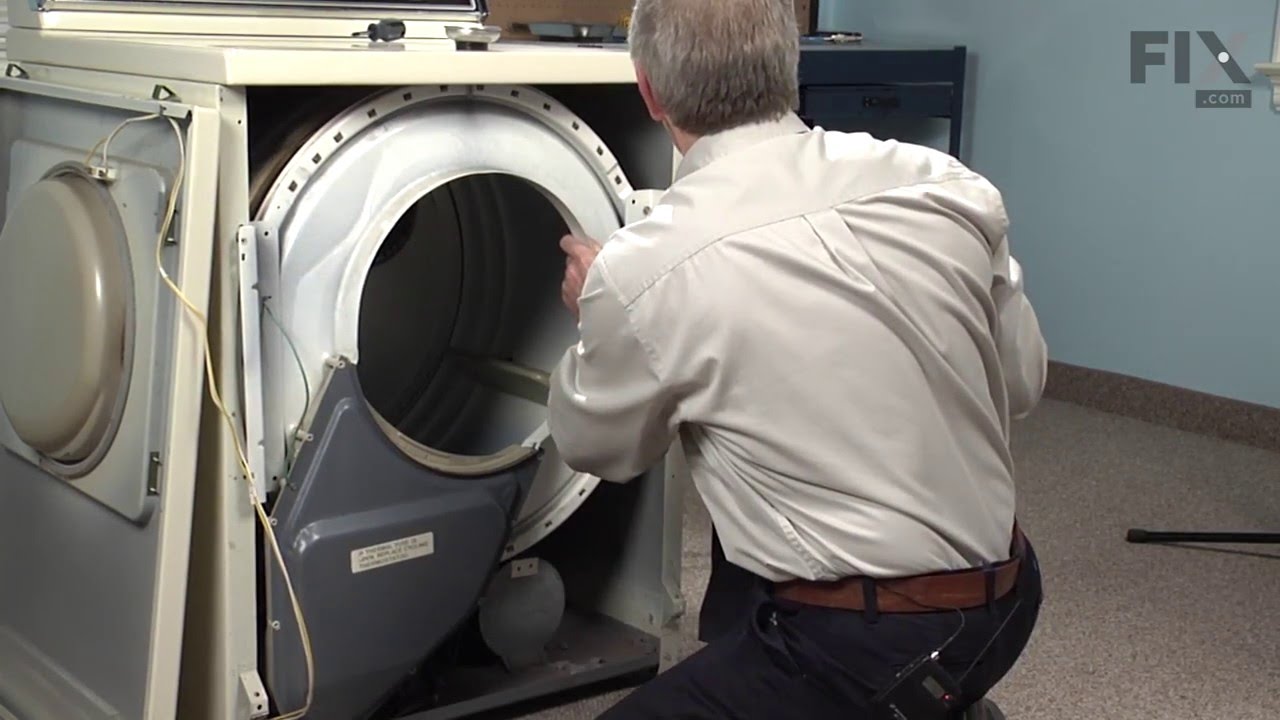

first, I unplug the power supply of the dryer then I removed the two screws at the bottom of the dryer then pulled out the front part of the dryer,unplugged the blue & yellow wire for the on/off switch for the door,at the back of the dryer I unscrew the pannel for the belt,disconect the belt,and I unscrew the four screws on both side of t

... Read more

he front pannel to remove the front cover of the drum. Once I removed the front cover of the drum I can now remove the drum itself to access the drum support roller. I unscrew the rollers then replace it with the new once. It was an easy job.

Thank you.

Thank you.

Read less

Was this instruction helpful to you?

Thank you for voting!

- Customer:

- Richard from Greenville, NH

- Parts Used:

- 12002022

- Difficulty Level:

- A Bit Difficult

- Total Repair Time:

- More than 2 hours

- Tools:

- Nutdriver, Pliers, Screw drivers, Socket set, Wrench (Adjustable), Wrench set

Spinner making loud whining noise.

As Typical with this Neptune front load washer, the Water Seal fails to keep water from getting into the bearings. The bearings start to sound like a jet engine at high speed spins once the grease is washed out (nice grease splatter at the back of the cabinet). You can replace the Lip Seal but the bearings are not part of the kit. It i

... Read more

s a waste of time to replace the seal kit if the bearings are already bad or going bad. You can't buy the bearings from here or any other appliance part store. You have to purchase a new tub in order to get new bearings, at $500+. Not worth it. I purchased the Lip Seal Kit with the intention of removing the bearings and replacing. The instructions that come with the kit explain with diagrams how to disassemble. In order to remove the spinner from the outer tub, I had to remove the whole tub, place it face down on some 2x4's and hit the spinner shaft with a hammer and block of wood to get it out of the old bearings. It came out fairly quickly. I removed the old lip seal (you can use the two access holes at the back of the outer tub to bang out the lip seal with a nail) and using a hammer and screwdriver, banged out the front bearing in the outer tub from the back and through the back bearing. This took a little while of moving around the bearing edge and tapping out, especially since there is a pipe spacer between the 2 bearings. It can be moved partly out of the way. The spacer will fall out with the front bearing. I then removed the C-clip that holds in the back bearing and banged out using the same method as the front bearing but from the inside. It too took a lot of tapping around the edges due to lots of corrosion. Once I had the bearings out, I looked up the make and model printed on the covers. Order using a DDU designation which is a rubber seal on both sides, like originals. I cleaned up the bearing mounting surfaces using a dremel tool and wire brush attachment. Make sure you get the metal free of any contamination. Use grit paper if necessary. I also sanded down the spinner shaft and got the spindle nice and shiny. I inserted the larger front bearing first (use a little grease on outside edge), it was a very tight fit and had to tap in using a hammer and metal rod. Make sure it is all the way in. Install the new seal kit (mine was the crummy original design, not the revised one). With the spinner tub on the floor shaft up on some 2x4's (light coating of grease on shaft), place the outer tub over the spinner with the shaft inserting through the new bearing and out the back. The shaft isn't an interference fit with the front bearing so it should slide in easily. WIth the shaft fully inserted, install the pipe spacer (cleaned up) then place the back bearing (outside edge greased) over the shaft and into the outer tub. This is an interference fit and will have to be tapped into place. It also was a tight fit into the tub. WIth it part of the way into the tub, I installed the belt pulley and tightened it down using a longer bolt than supplied, and this pushed the bearing the rest of the way in. I then installed the the C-ring. Not sure why the C-ring is needed with the bearing being such a tight fit. I installed the tub assembly back into the washing machine cabinet and installed the pulley and belt.. After reassembling the complete washer (after much cleaning of dust and soap scum, etc) I ran the unit once with no clothes to make sure any contaminates (grease, etc) where washed out first. So far so good, nice and quiet. If it last me another 5-10 years I will be happy. It will fail again for the same reason since I had to use the same lame seal kit and didn't have the revised version un

Read less

Was this instruction helpful to you?

Thank you for voting!

- Customer:

- Michael from Cache, OK

- Parts Used:

- 12002022

- Difficulty Level:

- A Bit Difficult

- Total Repair Time:

- More than 2 hours

- Tools:

- Nutdriver, Pliers, Screw drivers, Socket set, Wrench (Adjustable), Wrench set

Bad bearings on inner drum

Unplug and turn off water.....Removed belt drive cover. Rolled belt off of pulley. Removed pulley from back of splined shaft. Removed front door and front panel. Removed two screws that hold top of washer down, 4 screws that hold detergent/bleach tray to top and tilted top back. Removed 4 screws that hold door seal assembly to frame

... Read more

. Popped clips from back of seal away from outer drum. Note locations to reinstall. Pulled small hose away from seal assembly (located at bottom of door seal. Removed door seal assembly. Removed torx screws from tumblers in inner drum to access nylock nuts that hold inner drum to spinner. Removed inner drum. Pulled spinner shaft from outter drum. Removed seal from inside outer drum where shaft passes through bearings. Knocked outside bearing out with drift from inside outer drum. Be careful no to nick/scratch bearing fit or shoulder. Go to the back of the machine and knock the inner bearing out using same method. TAKE YOUR TIME. Outer drum 600 bucks, so don't mess it up. Bearings are available at local bearing shop. NSK 6206DU and NSK 6207DU. Cleaned well and made sure that bearing fits were in good shape. Cleaned up spacer that fits between bearings. Note the way it comes out of the bearing holder (it is tapered on one end). Tapped outer race of inside and outside bearings into fits (barely) after lying the spacer between the bearings in the bearing sleeve. Used threaded rod and some washers of the proper size to pull bearings together. Tapped outer races to make sure that they were seated. Check spacer sleeve fit between inner races (hold it up in the proper location with your fingers....should be snug. Pressed new seal in per directions. Trial fit spinner into bearings/spacer. Installed pulley and belt. Note how bearing spacer and shoulders and pulley clamp inner races together so that you don't get any slip/slop/slap. Reassembled in reverse. Only problem I had was with the door latch manual releast that I accidently clamped between the bleach/detergent dispenser and lid when closing it up....had to adjust. Drank beer and bragged to wife. Been about 20 loads no....no leaks and as quiet as it was new. Took about 2 hours to take it apart and about 3 to put back together....Not a bad job. Definitely cheaper than an outer drum assembly.

Read less

Was this instruction helpful to you?

Thank you for voting!