Models

>

DG26CD

DG26CD Maytag Dryer

Jump to:

Find Part by Name

Keep searches simple, eg. "belt" or "pump".

Diagrams for DG26CD

Viewing 10 of 10Keep searches simple, eg. "belt" or "pump".

$13.50

This OEM drum support roller kit contains the parts needed to replace one roller on your dryer. This kit includes one drum roller and two bearings. Most dryers use two drum rollers, and it is recommen...

In Stock

Order within the next 6 hrs and your part ships today!

$32.48

This is a single OEM dryer drum belt. It measures 100 inches in length, 3/8 of an inch wide and has five ribs and four grooves. Keep in mind that this rubber drum belt will stretch over time, so if yo...

In Stock

Order within the next 6 hrs and your part ships today!

$14.70

This part is located on the front bulkhead of the dryer and helps the drum to rotate smoothly and quietly. If you notice a screeching or metal-on-metal noise while your appliance is operating, you may...

In Stock

Order within the next 6 hrs and your part ships today!

$9.81

The roller shaft is also known as a support roller shaft or a drum roller axle. It is a part in your dryer that the drum rollers spin on, helping your dryer to tumble. If your appliance is noisy while...

In Stock

Order within the next 6 hrs and your part ships today!

$22.88

The blower wheel is responsible for blowing heat into the dryer drum, and out of the exhaust vent. If you notice that your dryer is taking too long to dry or is make unusually loud noises, it may be t...

In Stock

Order within the next 6 hrs and your part ships today!

$7.88

Sometimes referred to as a retaining clip, the retaining ring is used to hold the drum support roller onto the shaft in your dryer. The clip may need to be replaced if you find that your dryer is nois...

In Stock

Order within the next 6 hrs and your part ships today!

If the lint filter in your dryer has become damaged or missing, this is a genuine OEM replacement part. The filter is used to trap lint and debris from entering the dryer vents, where it could be a fi...

No Longer Available

$47.91

This genuine OEM part is a radiant flame sensor for your gas dryer. It is used to determine when the temperature of the igniter is hot enough to ignite the gas. Once the igniter is hot enough, it allo...

In Stock

Order within the next 6 hrs and your part ships today!

$13.79

This roller shaft washer is just under an inch in diameter and is used for some of Whirlpool's brands of clothes dryers.Sold individually.

In Stock

Order within the next 6 hrs and your part ships today!

$38.35

This flat style igniter comes with a wire harness connector. This part ignites the gas within the dryer. Bracket is NOT included.

In Stock

Order within the next 6 hrs and your part ships today!

$13.45

This idler pulley shaft washer is used with many clothes dryers. It is less than an inch long, and it is black in color.

In Stock

Order within the next 6 hrs and your part ships today!

$19.26

This part is used to help the belt to rotate the drum. It is white and made of plastic with a metallic bearing in the center.

In Stock

Order within the next 6 hrs and your part ships today!

Questions and Answers

We're sorry, but our Q&A experts are temporarily unavailable.

Please check back later if you still haven't found the answer you need.

Common Problems and Symptoms for DG26CD

Viewing 7 of 7Noisy

Fixed by these parts

How to fix it

Door won’t close

Fixed by these parts

How to fix it

Marks left on clothes

Fixed by these parts

How to fix it

Too hot

Fixed by these parts

How to fix it

Drum Not Spinning

Fixed by these parts

How to fix it

Not Heating

Fixed by these parts

How to fix it

Touchpad does not respond

Fixed by these parts

How to fix it

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

noisy rollers, broken latch

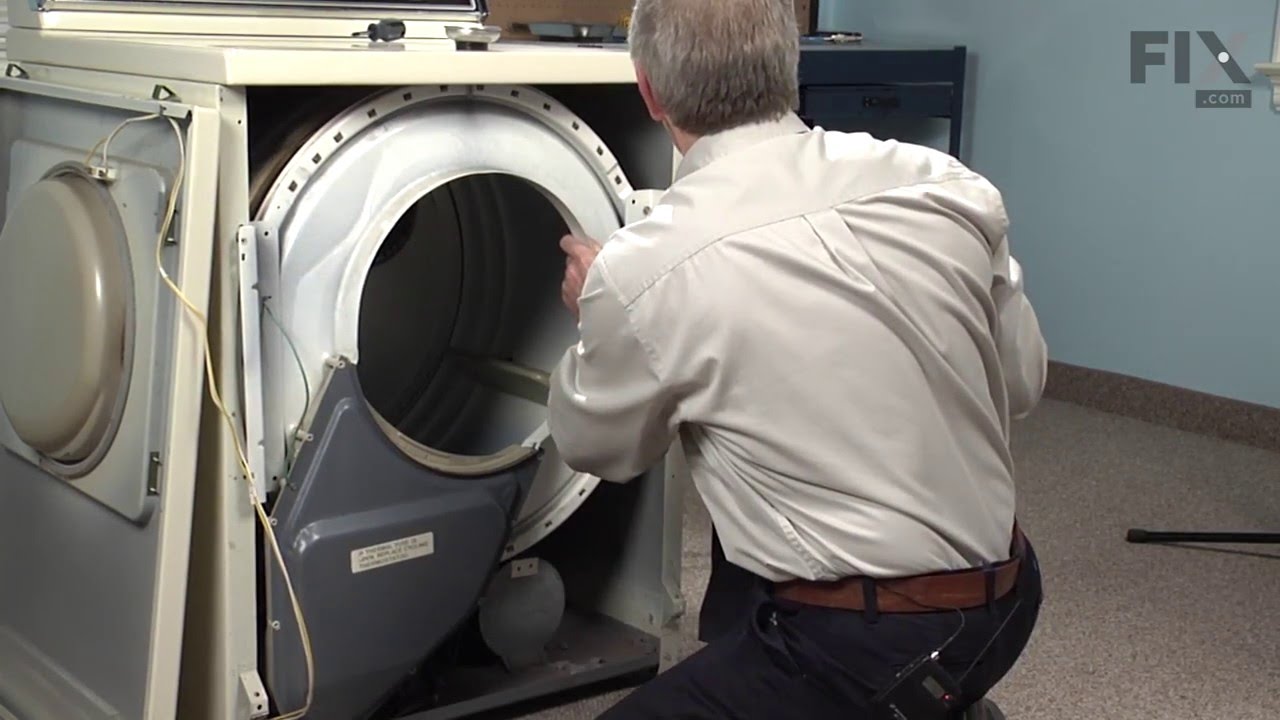

first, I unplug the power supply of the dryer then I removed the two screws at the bottom of the dryer then pulled out the front part of the dryer,unplugged the blue & yellow wire for the on/off switch for the door,at the back of the dryer I unscrew the pannel for the belt,disconect the belt,and I unscrew the four screws on both side of t

... Read more

he front pannel to remove the front cover of the drum. Once I removed the front cover of the drum I can now remove the drum itself to access the drum support roller. I unscrew the rollers then replace it with the new once. It was an easy job.

Thank you.

Thank you.

Read less

Was this instruction helpful to you?

Thank you for voting!

- Customer:

- Stephen from Lafayette, IN

- Parts Used:

- Y303836

- Difficulty Level:

- Really Easy

- Total Repair Time:

- 1- 2 hours

- Tools:

- Nutdriver, Pliers, Screw drivers

The blower fan (nylon) stripped off the motor shaft (steel)

Removed the front cover (screws on bottom 0f face)...removed blower cover....spring pliers to remove and install blower fan. the rest of the time was spent cleaning the inside of the shell as well as the vent. Reassembled and dryer runs better than it has for many years.

Was this instruction helpful to you?

Thank you for voting!

Belt broke on old machine.

1. Removed front of machine (2 screws at the bottom).

2. Removed 4 screws from inside the dryer, to take off the blower housing.

3. Removed 4 screws and took out the large metal piece which supports the drum at the front. Removed the drum.

4. Replaced the two rollers that support the drum in the rear. Cleaned the pins they ... Read more run on, and oiled very lightly. Also replaced the idler roller. I was surpirsed to see that these rollers use plain bearings, not ball bearings.

5. On the front support piece, drilled out the rivets for the glides, and replaced the worn out glides with new parts. Applied a little glue (3M weatherstrip adhesive) to the cork pieces, to glue them to the metal. Attached the plastic pieces over the cork pieces, and riveted in place using rivets that came with the glide kits.

6. Replaced front and rear felt seals. This was not as tricky as I expected it to be. They were held in by metal tabs. Glued the ends where they came together.

7. Replaced the felt blower seal. Glued to the blower housing.

8. Reinstalled the drum, installed new belt, which came with good instructions (luckily).

9. Reassembled front support piece and the front of the cabinet.

I also cleaned the lint from the cabinet and from the vent hose.

In general, the job went without a hitch, and the machine probably has quite a few years left, despite the fact that it's 18 years old. This gives me a good feeling.

I'd say this would be challenging, though, for someone who is not pretty experienced with machinery repair. Also, the cost of the parts was significant enough that it would not have been unreasonable to have opted for a new machine.

2. Removed 4 screws from inside the dryer, to take off the blower housing.

3. Removed 4 screws and took out the large metal piece which supports the drum at the front. Removed the drum.

4. Replaced the two rollers that support the drum in the rear. Cleaned the pins they ... Read more run on, and oiled very lightly. Also replaced the idler roller. I was surpirsed to see that these rollers use plain bearings, not ball bearings.

5. On the front support piece, drilled out the rivets for the glides, and replaced the worn out glides with new parts. Applied a little glue (3M weatherstrip adhesive) to the cork pieces, to glue them to the metal. Attached the plastic pieces over the cork pieces, and riveted in place using rivets that came with the glide kits.

6. Replaced front and rear felt seals. This was not as tricky as I expected it to be. They were held in by metal tabs. Glued the ends where they came together.

7. Replaced the felt blower seal. Glued to the blower housing.

8. Reinstalled the drum, installed new belt, which came with good instructions (luckily).

9. Reassembled front support piece and the front of the cabinet.

I also cleaned the lint from the cabinet and from the vent hose.

In general, the job went without a hitch, and the machine probably has quite a few years left, despite the fact that it's 18 years old. This gives me a good feeling.

I'd say this would be challenging, though, for someone who is not pretty experienced with machinery repair. Also, the cost of the parts was significant enough that it would not have been unreasonable to have opted for a new machine.

Read less

Was this instruction helpful to you?

Thank you for voting!