Models

>

MDE14PDAGW

MDE14PDAGW Maytag Dryer

Jump to:

Find Part by Name

Keep searches simple, eg. "belt" or "pump".

Diagrams for MDE14PDAGW

Viewing 9 of 9Keep searches simple, eg. "belt" or "pump".

$13.50

This OEM drum support roller kit contains the parts needed to replace one roller on your dryer. This kit includes one drum roller and two bearings. Most dryers use two drum rollers, and it is recommen...

In Stock

Order within the next 9 hrs and your part ships today!

$14.70

This part is located on the front bulkhead of the dryer and helps the drum to rotate smoothly and quietly. If you notice a screeching or metal-on-metal noise while your appliance is operating, you may...

In Stock

Order within the next 9 hrs and your part ships today!

$9.81

The roller shaft is also known as a support roller shaft or a drum roller axle. It is a part in your dryer that the drum rollers spin on, helping your dryer to tumble. If your appliance is noisy while...

In Stock

Order within the next 9 hrs and your part ships today!

If your dryer is noisy while operating, or will not tumble at all, there may be an issue with the drum belt. Over time, the rubber can become brittle and snap, and the belt will need to be replaced. T...

In Stock

Order within the next 9 hrs and your part ships today!

$7.88

Sometimes referred to as a retaining clip, the retaining ring is used to hold the drum support roller onto the shaft in your dryer. The clip may need to be replaced if you find that your dryer is nois...

In Stock

Order within the next 9 hrs and your part ships today!

If your dryer is making excessive noise, or it will not tumble, there may be an issue with the idler pulley wheel. The idler pulley wheel is attached to the idler bracket and is used to secure the dry...

In Stock

Order within the next 9 hrs and your part ships today!

$13.79

This roller shaft washer is just under an inch in diameter and is used for some of Whirlpool's brands of clothes dryers.Sold individually.

In Stock

Order within the next 9 hrs and your part ships today!

In Stock

Order within the next 9 hrs and your part ships today!

$13.45

This idler pulley shaft washer is used with many clothes dryers. It is less than an inch long, and it is black in color.

In Stock

Order within the next 9 hrs and your part ships today!

$15.93

This seal can be used for the front or rear drum. Adhesive is NOT included. For adhesive search: WPY055980

In Stock

Order within the next 9 hrs and your part ships today!

$46.00

This part moves the clothes around inside your dryer and helps to direct the flow of hot air during the drying cycle.

In Stock

Order within the next 9 hrs and your part ships today!

$41.62

This part moves the clothes around inside your dryer and helps to direct the flow of hot air during the drying cycle.

NOTE: Screws are NOT included.

In Stock

Order within the next 9 hrs and your part ships today!

Questions and Answers

We're sorry, but our Q&A experts are temporarily unavailable.

Please check back later if you still haven't found the answer you need.

Common Problems and Symptoms for MDE14PDAGW

Viewing 6 of 6Noisy

Fixed by these parts

How to fix it

Door won’t close

Fixed by these parts

How to fix it

Marks left on clothes

Fixed by these parts

How to fix it

Too hot

Fixed by these parts

How to fix it

Drum Not Spinning

Fixed by these parts

How to fix it

Touchpad does not respond

Fixed by these parts

How to fix it

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

- Customer:

- Frederick W. from Austin, TX

- Parts Used:

- WP6-3705180, WP6-3700340, WP6-3129480, WPY312527, WP33002535, W10410997, WP312535, 306508, 12001541

- Difficulty Level:

- Easy

- Total Repair Time:

- More than 2 hours

- Tools:

- Nutdriver, Screw drivers, Wrench set

Motor buzzed and dryer drum would not spin when pressing start

From the first time the motor buzzed (but dryer tumbler then started to turn), 2 weeks elapsed for the dryer drum to stop turning altogether. If this occurs, DO NOT continue to push the start button because the motor armature wiring will heat up and the insulation will begin to melt and smell - a SAFETY HAZARD. Unplug dryer and lockout/

... Read more

tagout as appropriate.

Through basic troubleshooting, discovered the motor had seized up. Since the unit was about 10 years old and it had to be disassembled for replacement, the decision was made to replace "likely to fail mechanical components including motor, belt, both rear drum rollers/shafts, idler arm pulley/assembly/wheel, associated washers, snap rings and both front glides. Reviewed the PartSelect website and drawings, ordered the parts and they delivered on time. Buy the correct sized snap rings at a local hardware, they're much less expensive. Also once inside your dryer, you'll likely find alot of lint to vacuum out...have fun.

I went online and Googled several resources that showed how to remove the front dryer panels, as well as PartSelect repair stories. From that point on, I took photos as I was disassembling so I would know how to put it back together. Utilize pictures or whatever system you prefer to keep track of taking something apart and putting it back together.

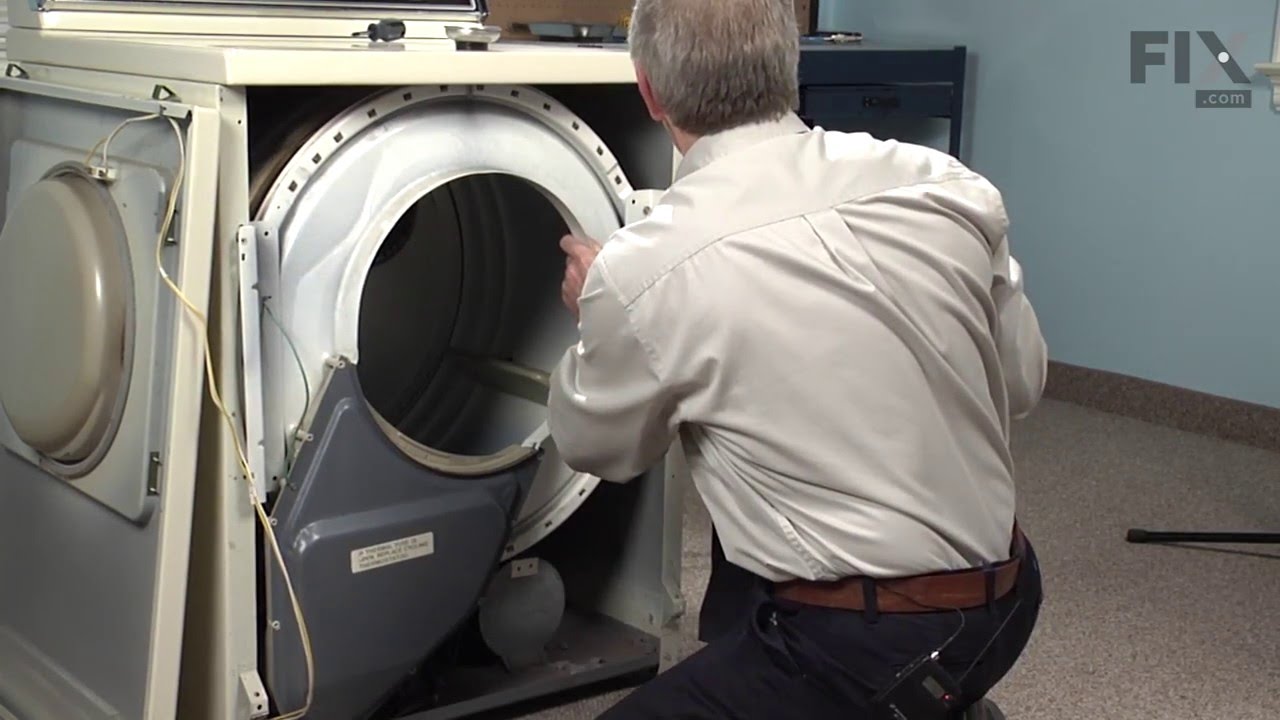

Remove the dryer door, then the front panel Disconnect wires to the light, dryness sensor and door switch. Note belt and pulley configuration that is near the motor-this will help you later when reinstalling the belt. Also note if the ribbed side or the flat side of the belt is against the outer drum wall. Remove the door shroud.

Slip the belt off the idler pulley wheel. Remove front drum support, then dryer drum Note which end of the dryer drum is the front and the orientation of the glides on the drum support. Discard old belt. Drill out and remove the old front glide supports, then install/rivet the new glides.

Remove both old rear drum rollers/shafts, washers, etc. The rear drum roller shafts are secured to a back bracket by a hex nut....feel around you'll figure it out. Replace new roller shafts. Lightly grease using a high quality silicon grease, then replace new washers, roller, snap ring, etc

Carefully unplug wiring harness on motor, there are fragile clips on each end. Don't forget a separate ground wire from the harness is attached to the motor mount bracket. Carefully release tension on the idler arm spring. Using the correct size nut driver, remove three screws (on this model) then take out the motor/idler arm assembly. Remove the old idler arm/pulley assembly. Remove the motor mount clips on each end of the mount (I used a wide blade screwdriver). Remove and replace the motor. Motor configurations changed after Whirlpool bought Maytag, so orient it correctly insuring mounting gasket "nubs" on each end of the motor correspond to the cutouts on the motor mount. Reinstall the motor mount clips. Replace the new idler arm assembly/pulley wheel; grease moving parts with high quality wheel bearing grease. Replace motor/mount bracket assembly back into the dryer. Replace ground wire to motor mount bracket and plug wiring harness back in. Reinstall idler arm spring.

Place belt back on the dryer drum and move into place on rear rollers. Reinstall front drum support. Dryer drum should turn relatively easy. Insure belt is oriented on the drum correctly before connecting belt to motor shaft end and idler arm wheel pulley (the picture you took comes in handy here).

Reinstall the rest of the parts in reverse.

Through basic troubleshooting, discovered the motor had seized up. Since the unit was about 10 years old and it had to be disassembled for replacement, the decision was made to replace "likely to fail mechanical components including motor, belt, both rear drum rollers/shafts, idler arm pulley/assembly/wheel, associated washers, snap rings and both front glides. Reviewed the PartSelect website and drawings, ordered the parts and they delivered on time. Buy the correct sized snap rings at a local hardware, they're much less expensive. Also once inside your dryer, you'll likely find alot of lint to vacuum out...have fun.

I went online and Googled several resources that showed how to remove the front dryer panels, as well as PartSelect repair stories. From that point on, I took photos as I was disassembling so I would know how to put it back together. Utilize pictures or whatever system you prefer to keep track of taking something apart and putting it back together.

Remove the dryer door, then the front panel Disconnect wires to the light, dryness sensor and door switch. Note belt and pulley configuration that is near the motor-this will help you later when reinstalling the belt. Also note if the ribbed side or the flat side of the belt is against the outer drum wall. Remove the door shroud.

Slip the belt off the idler pulley wheel. Remove front drum support, then dryer drum Note which end of the dryer drum is the front and the orientation of the glides on the drum support. Discard old belt. Drill out and remove the old front glide supports, then install/rivet the new glides.

Remove both old rear drum rollers/shafts, washers, etc. The rear drum roller shafts are secured to a back bracket by a hex nut....feel around you'll figure it out. Replace new roller shafts. Lightly grease using a high quality silicon grease, then replace new washers, roller, snap ring, etc

Carefully unplug wiring harness on motor, there are fragile clips on each end. Don't forget a separate ground wire from the harness is attached to the motor mount bracket. Carefully release tension on the idler arm spring. Using the correct size nut driver, remove three screws (on this model) then take out the motor/idler arm assembly. Remove the old idler arm/pulley assembly. Remove the motor mount clips on each end of the mount (I used a wide blade screwdriver). Remove and replace the motor. Motor configurations changed after Whirlpool bought Maytag, so orient it correctly insuring mounting gasket "nubs" on each end of the motor correspond to the cutouts on the motor mount. Reinstall the motor mount clips. Replace the new idler arm assembly/pulley wheel; grease moving parts with high quality wheel bearing grease. Replace motor/mount bracket assembly back into the dryer. Replace ground wire to motor mount bracket and plug wiring harness back in. Reinstall idler arm spring.

Place belt back on the dryer drum and move into place on rear rollers. Reinstall front drum support. Dryer drum should turn relatively easy. Insure belt is oriented on the drum correctly before connecting belt to motor shaft end and idler arm wheel pulley (the picture you took comes in handy here).

Reinstall the rest of the parts in reverse.

Read less

Was this instruction helpful to you?

Thank you for voting!

- Customer:

- Teresa from Pace, FL

- Parts Used:

- WP33002032, WP33001755

- Difficulty Level:

- Easy

- Total Repair Time:

- 15 - 30 mins

- Tools:

- Nutdriver, Screw drivers

dried too many shoes and broke the baffles

removed door, removed screws to lift top panel, removed screws that held old baffles, replaced with new baffles, took off front panel and cleaned out excess lint while I was in there.

Was this instruction helpful to you?

Thank you for voting!

- Customer:

- Paul from Mt. Pleasant, SC

- Parts Used:

- LA-1003

- Difficulty Level:

- Really Easy

- Total Repair Time:

- Less than 15 mins

- Tools:

- Screw drivers

catch mounted on door broke

The door had always opened with the wrong swing and it wasn't til I needed to repair this that I noticed you could change the swing. I changed the swing of the door and then noticed that the clip was included on both sides so i did not need to repair the catch. I still have the part so when it breaks again, I can just pop it in.

Was this instruction helpful to you?

Thank you for voting!