Some of the parts we sell are eligible for mail-in rebates since we can recycle them. We will display any applicable rebates in your shopping cart. To redeem your rebate, contact Customer Service after you have received your part.

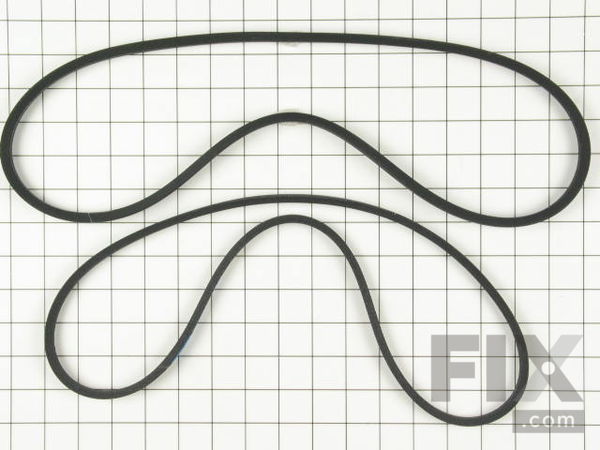

Belt Kit

- Fix Number:

- FIX2005284

- Manufacturer #:

- 12112425

- Manufactured by:

- Whirlpool

- Product Description

- Over time, the belts in your washer can either stretch out and sag, or become brittle and snap. When this happens, it can result in the belt losing its grip and will not be able to spin or drain the tub. If this happens, the belts will need to be replaced. This OEM belt kit includes the drive belt and the pump belt, which are both V-shaped, and made of black rubber. The pump belt is located between the motor and pump under the washer, and the drive belt is looped around the drive and motor pulley at the bottom of the machine. This repair is easiest to complete if the washer is placed on its back, and you will need to disconnect the power and water supply.

- Works with the following brands:

- Maytag, Jenn-Air, International

- Works with the following products

- Washer, Washer Dryer Combo

- Fixes the following symptoms

- Burning smell, Will not agitate, Will not drain, Spins slowly

- Part# 12112425 replaces these:

- AP4011179, 402507, 12112425, 12112425VP, 2-10024, 2-11124, 2-11125, 210024, 211124, 211125, 22002570, 22002571, 8195-112, 8195-125, P50-020, P50-021, W10175481, WP211125

Product Description

Over time, the belts in your washer can either stretch out and sag, or become brittle and snap. When this happens, it can result in the belt losing its grip and will not be able to spin or drain the tub. If this happens, the belts will need to be replaced. This OEM belt kit includes the drive belt and the pump belt, which are both V-shaped, and made of black rubber. The pump belt is located between the motor and pump under the washer, and the drive belt is looped around the drive and motor pulley at the bottom of the machine. This repair is easiest to complete if the washer is placed on its back, and you will need to disconnect the power and water supply.

-

Works with the following brands:Maytag, Jenn-Air, International

-

Works with the following products:Washer, Washer Dryer Combo

-

Fixes the following symptoms:Burning smell, Will not agitate, Will not drain, Spins slowly

-

Part# 12112425 replaces these:AP4011179, 402507, 12112425, 12112425VP, 2-10024, 2-11124 ... Show more , 2-11125, 210024, 211124, 211125, 22002570, 22002571, 8195-112, 8195-125, P50-020, P50-021, W10175481, WP211125 Show less

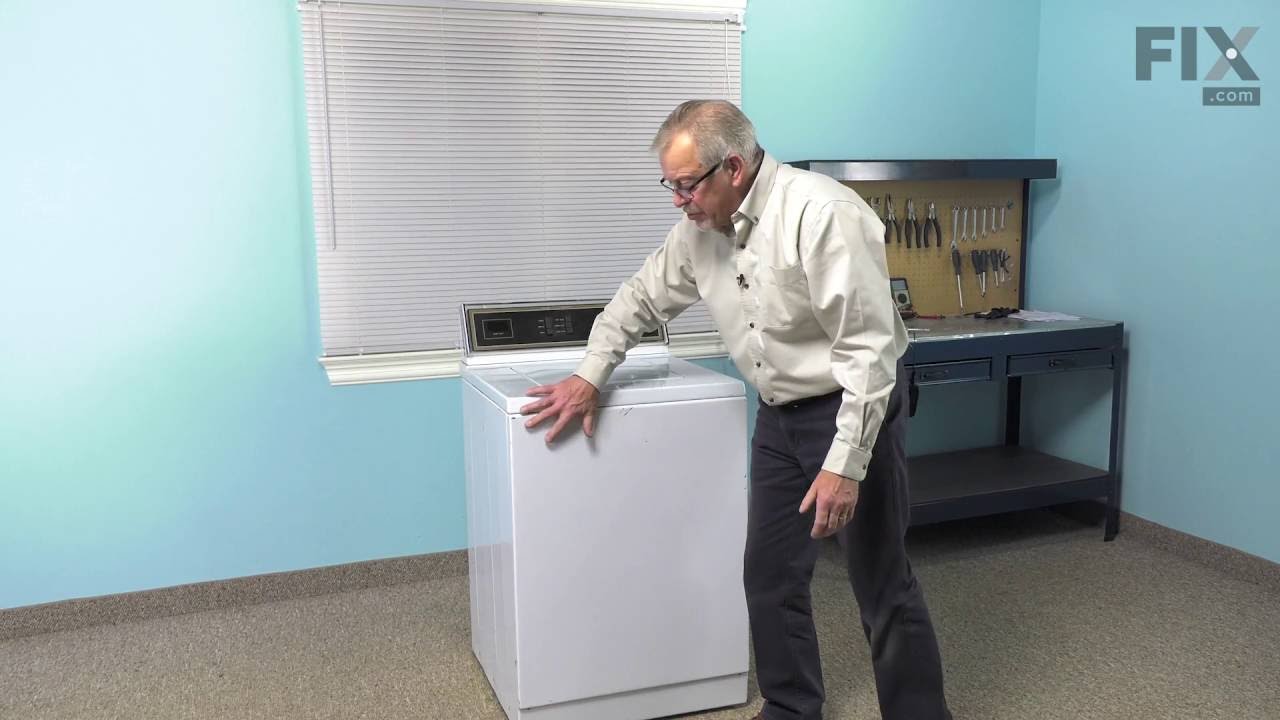

Videos For installing this part.

Replacing your Belt Kit

Questions and Answers

We're sorry, but our Q&A experts are temporarily unavailable.

Please check back later if you still haven't found the answer you need.

- < Prev

- 1

- Next >

Try using some different or simpler keywords, or submit your new question by using the "Ask a Question" button above!

2 people found this helpful.

Installation Instructions Provided by Fix customers like you.

- < Prev

- 1

- 2

- 3

- Next >

- Customer:

- George from Burnt Ranch, CA

- Parts Used:

- 12112425

- Difficulty Level:

- Easy

- Total Repair Time:

- 15 - 30 mins

- Tools:

- Nutdriver, Pliers, Screw drivers

- Customer:

- Roland from Noert Andover, MA

- Parts Used:

- 12112425

- Difficulty Level:

- Very Easy

- Total Repair Time:

- 15 - 30 mins

- Tools:

- Nutdriver, Pliers, Screw drivers

- Customer:

- Erin from HINES, OR

- Parts Used:

- WP6-2022030, 12112425, 12002351

- Difficulty Level:

- Very Easy

- Total Repair Time:

- 1- 2 hours

- Tools:

- Nutdriver, Pliers, Screw drivers, Socket set

My Maytag washe ... Read more r is 24 years old, and still looks great. Not relishing the idea of the technology driven appliances today, I just wanted to repair my Maytag.

I followed the installation videos provided on the FIX.com website and they were spot-on, making removal and replacement of the motor, belts and drain pump very easy. I will say that after I initially installed the new washer motor, it seemed to hang over the front edge, too far forward, and I was afraid it would interfere with the washer front panel. I actually took the motor out again and rechecked it's attachment to the spring loaded base plate, thinking I had re-installed it incorrectly. However, it seemed to be the only orientation possible, so I re-assembled it and re-installed it in the washer frame. What I discovered was that once the belts were added to the motor pulley, it pulled the motor into the correct position inside the washer frame, so my worries were for nothing. Just follow the video and everything will work out as expected, for an easy repair!

I decided that as long as I was replacing the washer motor, I would also replace the belts and drain pump, essentially refurbishing my trusty Maytag. Now back together and a few loads run, my Maytag is running like new and I am extremely happy! Add if this isn't enough encouragement, I am a 57 year old woman who did my own washer repair, so don't hesitate to do yourself, with the help of FIX.com!

- Customer:

- Laurie from Commerce Township, MI

- Parts Used:

- 12112425

- Difficulty Level:

- Very Easy

- Total Repair Time:

- Less than 15 mins

- Tools:

- Screw drivers

- Customer:

- Lawrence from Little Rock, AR

- Parts Used:

- 12112425

- Difficulty Level:

- Really Easy

- Total Repair Time:

- Less than 15 mins

- Customer:

- Don from Alexandria, IN

- Parts Used:

- 12112425

- Difficulty Level:

- Very Easy

- Total Repair Time:

- Less than 15 mins

- Customer:

- Paul from Virginia Beach, VA

- Parts Used:

- 12112425

- Difficulty Level:

- Really Easy

- Total Repair Time:

- 15 - 30 mins

- Tools:

- Screw drivers

- Customer:

- Alan from Fishers, IN

- Parts Used:

- WP22001650, 12112425

- Difficulty Level:

- Very Easy

- Total Repair Time:

- 15 - 30 mins

- < Prev

- 1

- 2

- 3

- Next >

- < Prev

- 1

- Next >

Model Compatibility

Manufacturer Part Number: 12112425