Some of the parts we sell are eligible for mail-in rebates since we can recycle them. We will display any applicable rebates in your shopping cart. To redeem your rebate, contact Customer Service after you have received your part.

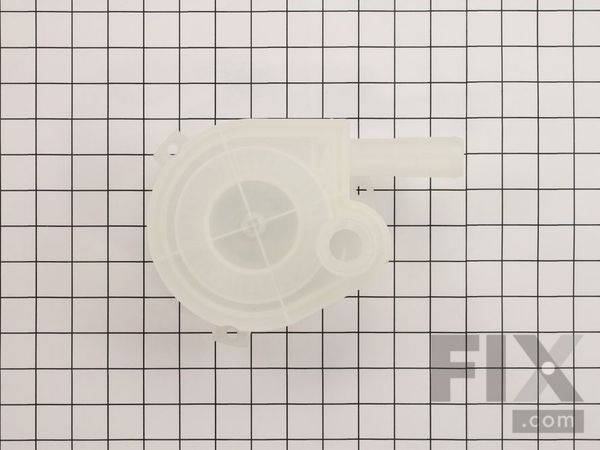

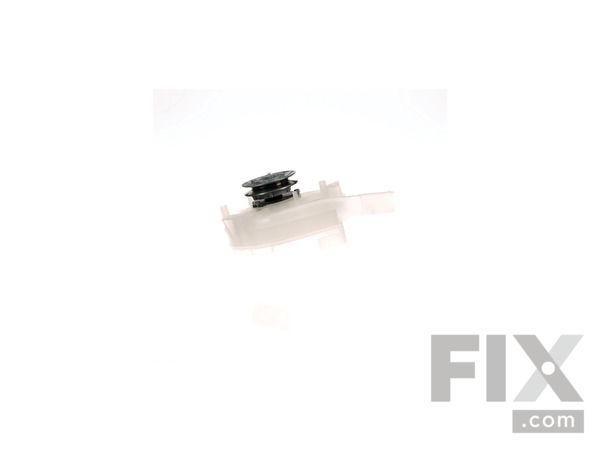

Washer Drain Pump

Works With Model LNC6762B71!

$120.13

In Stock

- Fix Number:

- FIX11741803

- Manufacturer #:

- WP35-6780

- Manufactured by:

- Whirlpool

Works With Model LNC6762B71!

- Product Description

- This pump helps expel water from the washing machine and is activated after the spin speed is maintained for a specific period of time. NOTE: This is a redesigned part. The pump now mounts on to the base of the washer - no mounting plate needed.

- Works with the following brands:

- Maytag, Admiral, Magic Chef, Hoover

- Works with the following products

- Washer

- Fixes the following symptoms

- Will not drain, Leaking, Burning smell, Will not agitate

- Part# WP35-6780 replaces these:

- AP6008663, 21001873, 21002219, 21002240, 35-6780, WP35-6780VP

Part Number Cross Reference

Product Description

This pump helps expel water from the washing machine and is activated after the spin speed is maintained for a specific period of time. NOTE: This is a redesigned part. The pump now mounts on to the base of the washer - no mounting plate needed.

-

Works with the following brands:Maytag, Admiral, Magic Chef, Hoover

-

Works with the following products:Washer

-

Fixes the following symptoms:Will not drain, Leaking, Burning smell, Will not agitate

-

Part# WP35-6780 replaces these:AP6008663, 21001873, 21002219, 21002240, 35-6780, WP35-6780VP

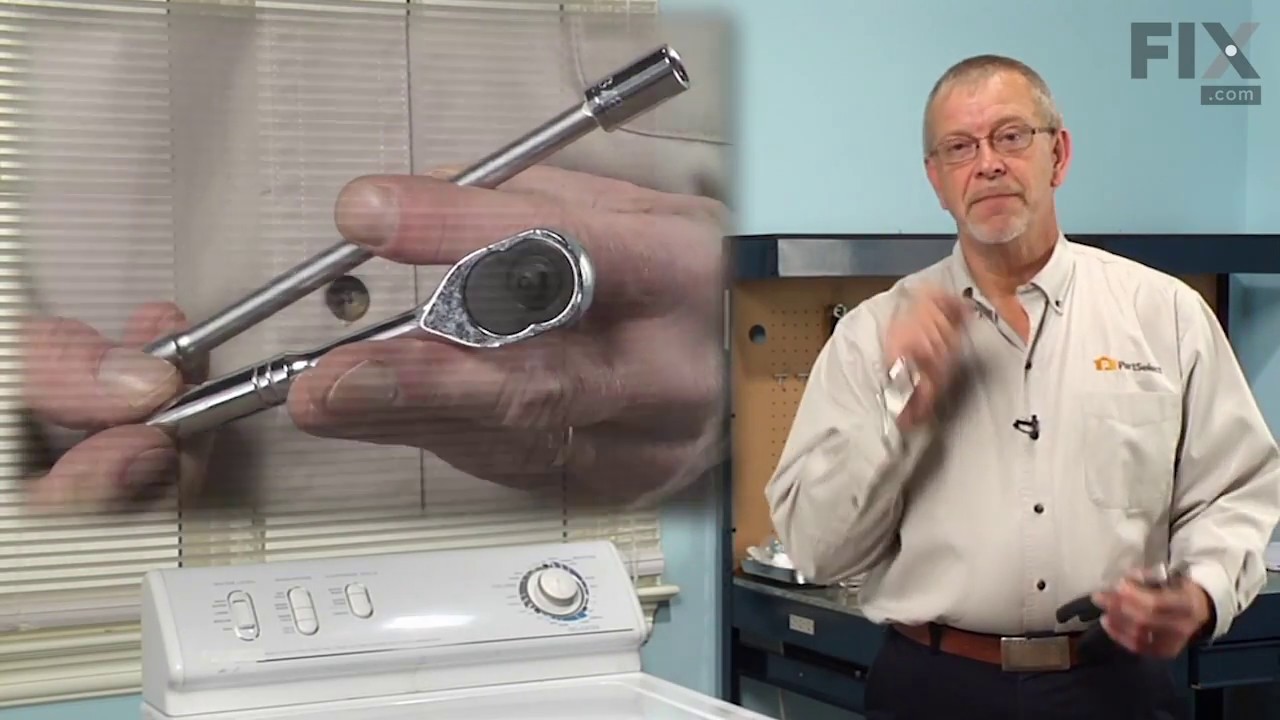

Videos For installing this part.

Replacing your Washer Drain Pump

Questions and Answers

We're sorry, but our Q&A experts are temporarily unavailable.

Please check back later if you still haven't found the answer you need.

Related Parts Additional or alternate parts to consider.

Installation Instructions Provided by Fix customers like you.

- < Prev

- 1

- 2

- 3

- Next >

Sort by:

Search filter:

Clear Filter

Your search term must have 3 or more characters.

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Sorry, we couldn't find any existing installation instruction that matched.

Pump had stop displacing water at spin cycle

Facing washer placed it on right side exposing underneath. Pump and transmission bearing items are accessible from this position. Followed step by step instructions contained with each part. Placed unit upright,supplied power and ran smallest allowed cycle to test. Unit works like new. Actually spin drys better,dryer clothes which works o

... Read more

ur older dryer less. Great tune-up and should give us several more years of service.

Read less

8 of 8 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

- Customer:

- James from Vienna, VA

- Parts Used:

- WP35-6780, WP21352320

- Difficulty Level:

- Very Easy

- Total Repair Time:

- 30 - 60 mins

- Tools:

- Nutdriver, Socket set, Wrench (Adjustable)

Uneven grinding whirl sound during certain parts of the cycle

The first thing I did was to pull the clothes washer away from the wall far enough that I could access the back side. My model has a small 15 inch square access panel towards the bottom that allows one to access the interior where the wash basin, drive train, motor and pump are located. After watching a few of the very helpful fix it vi

... Read more

deos online, I also noted that the pulley and drive belt were located on the under side of the washer. So I oriented the washer away from the wall so I could lean it back and also take a look at the underside to inspect the belt. The sound that I was hearing was something between the noise you might hear from a car whose belt has gone bad, or the sound that a large rolling commercial cabinet with big caster wheels would make when its wheel bearings are shot. The later being more of a grinding noise where the former is more of a whirl or squeal type of noise. Based on what the sound reminded me of, I naturally was interested in any parts of the washer where there might be a belt and things that turn with bearing like parts. Upon inspection of the belt under the washer I noticed that the belt was delaminating in a small 1/2 inch section, which suggested that this was an easy diagnosis and fix - it needed to be replaced. However, the sound the clothes washer was making also had a hint of grinding that was uneven in nature, suggesting the real problem was more metal/mechanical in nature. I returned the washer to its upright position and ran a small load with the cover to the access panel off, so I could see the wash basin, drive train, motor and pump in action. I was particularly interested in seeing if I could more clearly identify where the grinding whirl sound was coming from and what part of the cycle it was being caused by. The sound happened at certain times which also provided some clues as to what might be causing it. After listening and watching a cycle through the access panel, I determined that the sound was not the motor and didn't seem to be associated with the drive train or the basin. All that was left was the drain pump. At this point, I returned the washer to its normal location and ordered both a drive belt and a new drain pump from this site. A few days later the parts showed up on my doorstep earlier than promised. I then returned to my washer and pulled it away from the wall again so I could easily access the back and the panel. I also positioned it so I could lean the washer far enough to access the under side where the belt is. The belt drive is made up of the motor, the basin drive train and the drain pump. That is to say that the motor spins a pulley to which the belt is attached, which in turn spins the basin pulley or the drain pump pulley depending on the direction the motor spins. The first thing you must do before you start poking around and removing anything is to unplug the unit from the wall. Don't be stupid and choose to die on a laundry room floor. Once unplugged, leaned the washer so I could remove the old belt. I recommend watching the belt video as it shows the technique for removing and installing the belt - it is super easy. Takes less than 20 seconds. Before installing my new belt, I leaned the washer back to the floor. The belt creates some tension on the drain pump since they are connected by way of the pulley under the washer. It is necessary to remove the belt before attempting to remove the drain pump. Removing the drain pump is slightly more difficult than the belt, but completely doable for most anybody. Again, I recommend watching the very helpful drain pump video offered online with this site. The hardest part is dealing with the hose clamps. Using an adjustable pliers you have to simultaneously pinch the clamp while sliding it up and off or over the hose. Once you do that you are half way there. You can then slide the hoses off the plastic pump inlet and outlet. I recommend making sure you have run a full cycle so that your basin is as drained as it possibly can be. My pump was working well enough to do this before I started the repair job. Even then, when you pull the hose off the inlet or outlet of the pump, you will have approximately 3-5 cups of water drain out of the hose. Not a big deal if you preposition a few towels around the base of the inlet and outlet of the pump. The second source of water is the water in the pump itself, which will spill a little as you start to remove the pump. To remove the pump you simply need to loosen three screws with a socket and driver. It can be a little awkward to get your tools in a position to loosen the screws, but there is enough room to do it. Once the screws are loose, you simply lift the pump off the floor and with it comes the drain pump pulley that the belt underneath is connected to. The next step is to install the new pump doing everything in reverse. Place the pump in the floor hole (new pump comes with new pulley), attac

Read less

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

- Customer:

- NICHOLAS from SUN CITY WEST, AZ

- Parts Used:

- WP35-6780

- Difficulty Level:

- A Bit Difficult

- Total Repair Time:

- 1- 2 hours

- Tools:

- Nutdriver, Screw drivers

THE DRAIN PUMP IS THE SAME DESIGN, BUT HAD NO METAL PLATE BETWEEN THE PUMP AND PULLEY.

THE DESIGN CHANGED SOMEWHAT, WITH NO METAL PLATE BETWEEN PULLEY AND THE PUMP, AND YOU HAVE TO ADAPT THE TWO SCREWS ON THE BOTTOM OF THE PUMP TO ATTACH TO THE BASE OF THE WASHER. I USED RUBBER V-SHAPED WASHERS TO SECURE THE BOTTOM OF THE PUMP TO THE BASE WHERE THE TWO PLASTIC SCREW HOLES STUCK OUT.

1 person

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

- Customer:

- Cecil & Jeannette from Fort Collins, CO

- Parts Used:

- WP35-6780, WP21352320

- Difficulty Level:

- Really Easy

- Total Repair Time:

- 30 - 60 mins

- Tools:

- Nutdriver, Pliers, Socket set

A loud screech followed by burned rubber smell stalled the drain pump. The outer drain pump bushing had failed.

We drained the wash tub and turned it on its' front. Turning each bottom pulley by hand soon revealed the drain pump pulley was frozen. The belt and rear panel were removed. The drain hoses were disconnected and three screws removed with a socket to remove the pump, which unlike some older models was easily accessible. Installation of th

... Read more

e new part and belt required about 15 minutes to complete the repair.

Read less

0 of 1 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

- Customer:

- Eddie from Channahon, IL

- Parts Used:

- WP35-6780

- Difficulty Level:

- Really Easy

- Total Repair Time:

- 30 - 60 mins

- Tools:

- Nutdriver, Pliers

Maching was making a lot of noise. Found pump drive pully falling apart.

Unplugged washing machine. Pulled the drain hose out of drain. Did not have to unhook the water supply lines. Was able to slide far enough off the wall to get to the rear access panel. Removed panel. Tilted washer to the front. Pulled drive belt off. Removed the water hoses using channel locks to loosen and move hose clamp. Capt

... Read more

ured water from hoses with a small bowl and towel. Pulled the 3 mounting screws off and pulled pump out. Installed new pump reversing the steps.

Read less

0 of 1 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

- Customer:

- Natalie from Albuquerque, NM

- Parts Used:

- WP35-6780

- Difficulty Level:

- Easy

- Total Repair Time:

- More than 2 hours

- Tools:

- Nutdriver, Pliers, Socket set, Wrench (Adjustable)

Washer stopped draining, had burning smell

I replaced the drain pump. The video on this website was very easy to follow, the only difference was that the drain pump was at the rear of my washer instead of the front, so I had to figure out how to get behind it and remove the rear access panel. The hardest part was not being able to see the screws anchoring the drain pump and not

... Read more

having a lot of space to work while removing them by feel. But even that wasn't too terribly bad. Mostly it just slowed me down.

Read less

0 of 1 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

- Customer:

- Bill from Pleasant Hill, CA

- Parts Used:

- WP35-6780

- Difficulty Level:

- Easy

- Total Repair Time:

- 30 - 60 mins

- Tools:

- Nutdriver, Pliers

Washing machine would not agitate or spin

Drained the water from the tub. Tipped over the machine onto the front panel so I could look under the washing machine. Took off the single belt from the motor, tub and water pump. The motor and tub would spin without any problem. But the water pump would not spin. Removed the access panel on the back of the washer, unscrewed the pum

... Read more

p from the washing machine frame and removed the water hose clamps. Removed the bad water pump and replaced the bad water pump with a new water pump. Reconnected everything, pushed the machine back onto its feet and turned the washing machine on. Worked perfectly.

Read less

0 of 1 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

- Customer:

- Joseph T from Hartsville, PA

- Parts Used:

- WP35-6780

- Difficulty Level:

- Very Easy

- Total Repair Time:

- 15 - 30 mins

- Tools:

- Nutdriver, Pliers, Socket set

noisy operation particularly in drain and spin cycles

Ordered drain pump based on chart @this site diagnosing percentage chart. Tilted machine back and put a block under the front to support the machine while I removed the belt. Put the machine back down on the floor.Used a putty knife to release the top at both front corners. Supported the top, so I could take the two screws that hold the f

... Read more

ront panel in place. Used a 5/16 nut driver to accomplish that. Tilted the front forward and lifted off the clips at the bottom of the cabinet. Then I removed the three screws that held the pump to the base, lifted the old pump out and installed the new one. then reassembled the machine reverse of taking it apart. All in all it is easier done than said!!

Read less

0 of 1 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

- Customer:

- Stanley from Kingsport, TN

- Parts Used:

- WP35-6780

- Difficulty Level:

- Really Easy

- Total Repair Time:

- 30 - 60 mins

- Tools:

- Nutdriver, Pliers, Socket set

Loud noise during spin cycle.

I ordered the replacement drain pump after leaning the machine forward and moving the belt manually and hearing the pump bearing. Following a video for a pump replacement for a similar model, I removed the front of the machine. Didn't need to do that. The pump is located in the right rear of my machine. Removing the access panel, the

... Read more

three hex head screws on the pump, and then the two hoses was quite easy. Reversing the process with the replacement pump eliminated the noise. Success!

Read less

0 of 1 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

- Customer:

- Callista from Blue Springs, MO

- Parts Used:

- WP35-6780

- Difficulty Level:

- Really Easy

- Total Repair Time:

- 30 - 60 mins

- Tools:

- Pliers, Screw drivers, Socket set

Fast and Easy.

I noticed a screeching noise coming for the vicinity of the drain pump on our washer. My husband and I bought our first house 3 years ago - the washer and dryer came with the house. So this was the first time I've had to deal with washing machine maintenance/repair. I got on Google and came to this site which had symptoms, parts for our m

... Read more

odel and an easy to understand video tutorial. Before I ordered parts I called Maytag to see a cost comparison for having it serviced versus doing what looked like a simple fix at home. They estimated nearly $450!!! Just to have a certified Maytag service person come out, order the part and replace what I already knew was likely the drain pump. So I took a chance and ordered the drain pump from this site (and a few other parts in case it wasn't the drain pump, which I later returned). My husband assisted and we got the job done in as little as 40 minutes. It would have been shorter if we had not had issues removing the old pump (the nuts were a little corroded from leaking drain pump water). We got the new pump in fairly quickly following the video tutorial on the product page, hooked the washer back up and did a test drive. Worked like a charm! It's been a little over a month now and the washing machine and new drain pump are holding up and working perfectly. Saved me (according to Maytag's estimate) nearly $370. Thank you Part Select!!!

Read less

0 of 1 people

found this instruction helpful.

Was this instruction helpful to you?

Thank you for voting!

- < Prev

- 1

- 2

- 3

- Next >

★

Customer Reviews

Filter By Rating:

- < Prev

- 1

- Next >

Sort by:

Search filter:

Clear Filter

Your search term must have 3 or more characters.

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Sorry, we couldn't find any existing reviews that matched. Try using some different or simpler keywords.

Michael O - August 14, 2020

Verified Purchase

Solved my leak issue

The part was a perfect match for my old part on my Maytag and easy to replace, thanks to the instructional video. My old one was leaking for some reason I couldn't diagnose.

Model Compatibility

This part works with the following models:

Fix Number: FIX11741803

Manufacturer Part Number: WP35-6780

Manufacturer Part Number: WP35-6780

Brand

Model Number

Description

✖

Mail-In Recycling Rebate