Models

>

CAE2745FQ0

CAE2745FQ0 Whirlpool Washer

Jump to:

Find Part by Name

Keep searches simple, eg. "belt" or "pump".

Diagrams for CAE2745FQ0

Viewing 7 of 7Keep searches simple, eg. "belt" or "pump".

$54.38

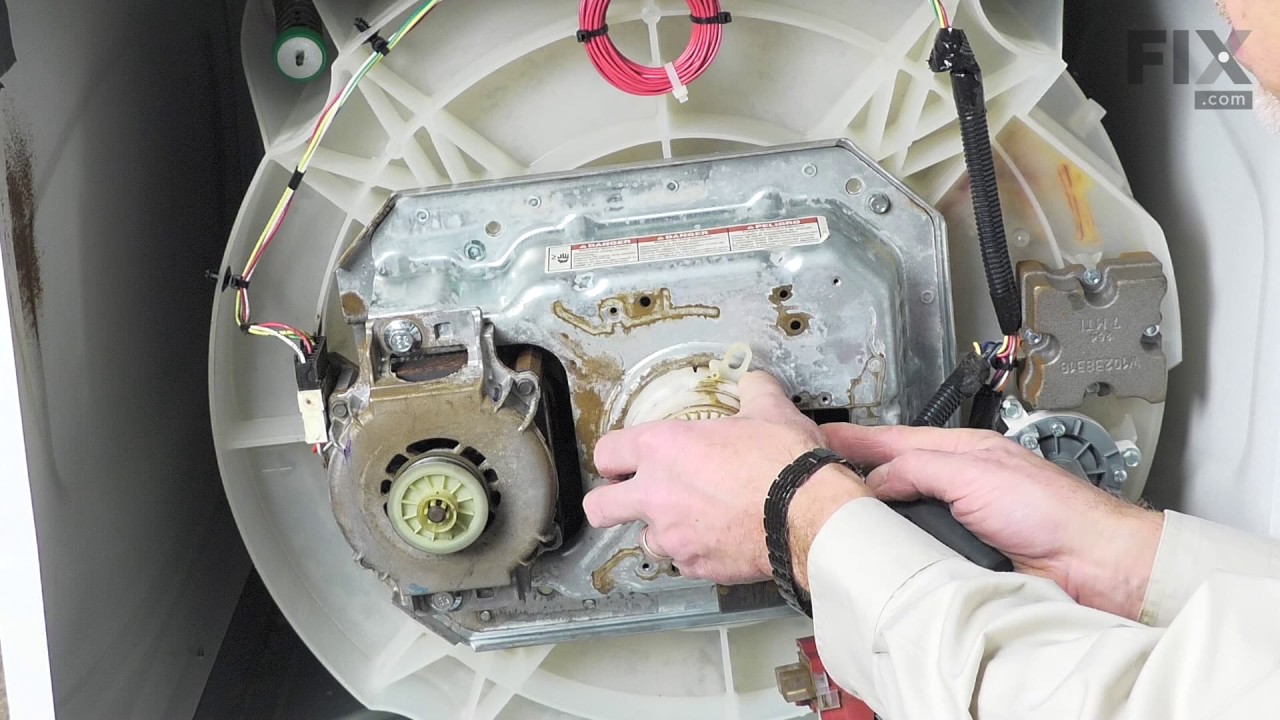

The washer drive pulley kit is also known as a replacement clutch assembly, or a cam kit. The drive pulley is found at the bottom of your washing machine, mounted to the drive shaft. Common symptoms i...

In Stock

Order within the next 3 hrs and your part ships today!

$5.42

This is a multi-use screw and can be used on a variety of appliances. The measurements of the screw are: 8/18 x 3/8. *Please note: the screw is sold individually. Refer to the manual provided by the m...

In Stock

Order within the next 3 hrs and your part ships today!

$8.00

This 18 ml bottle of white appliance touch-up paint is used to cover scratches or marks on your appliance. The white touch-up paint can be used on refrigerators, microwaves, ranges, clothes dryers, an...

In Stock

Order within the next 3 hrs and your part ships today!

In Stock

Order within the next 3 hrs and your part ships today!

$11.80

Sold individually. NOTE: The color on the screw may not be the same as the image, but will still function the same.

In Stock

Order within the next 3 hrs and your part ships today!

$44.48

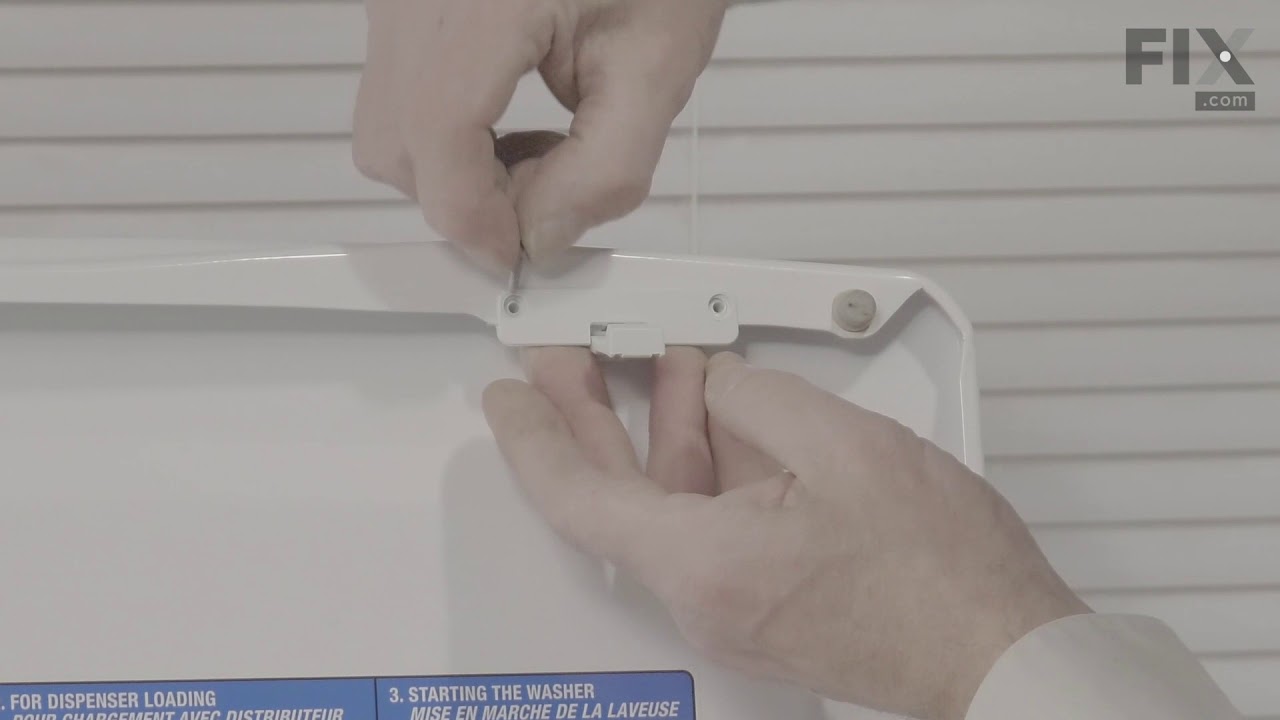

This part is the replacement lid latch or latch assembly for your top-load washer. The lid latch holds your washer door closed, and allows the washer to run its cycle. If the lid latch is damaged, you...

In Stock

Order within the next 3 hrs and your part ships today!

In Stock

Order within the next 3 hrs and your part ships today!

$149.62

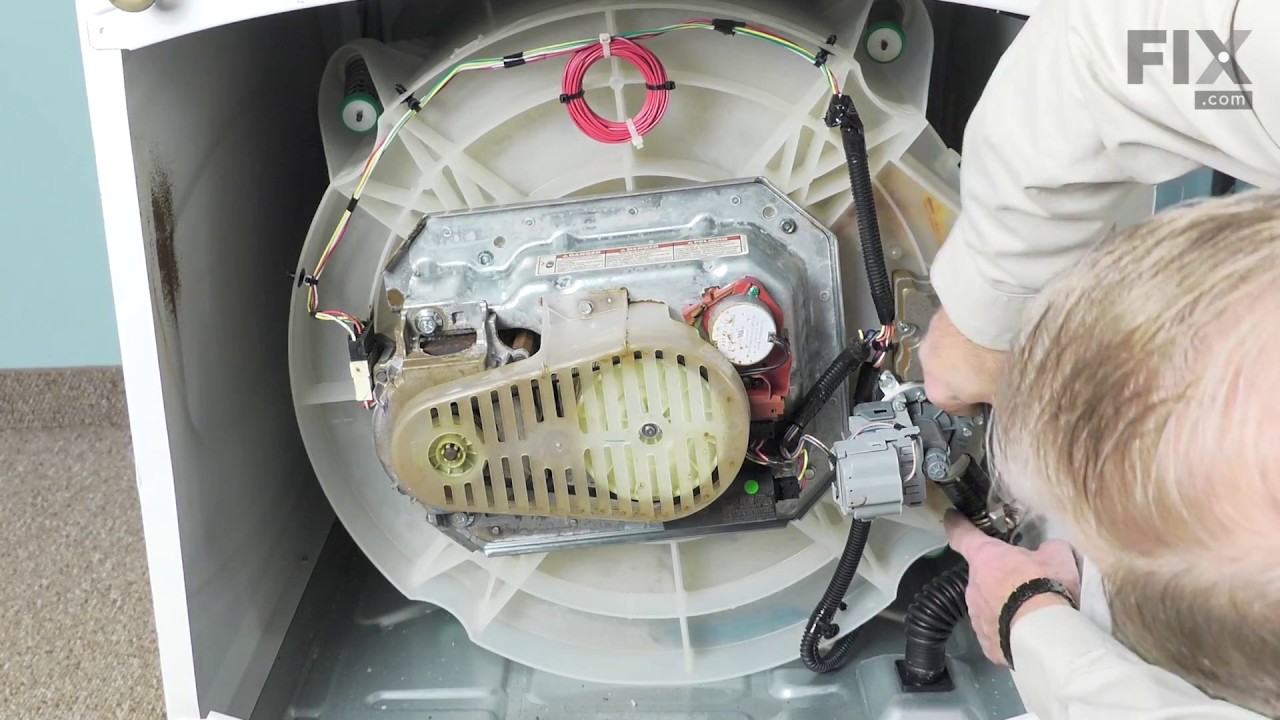

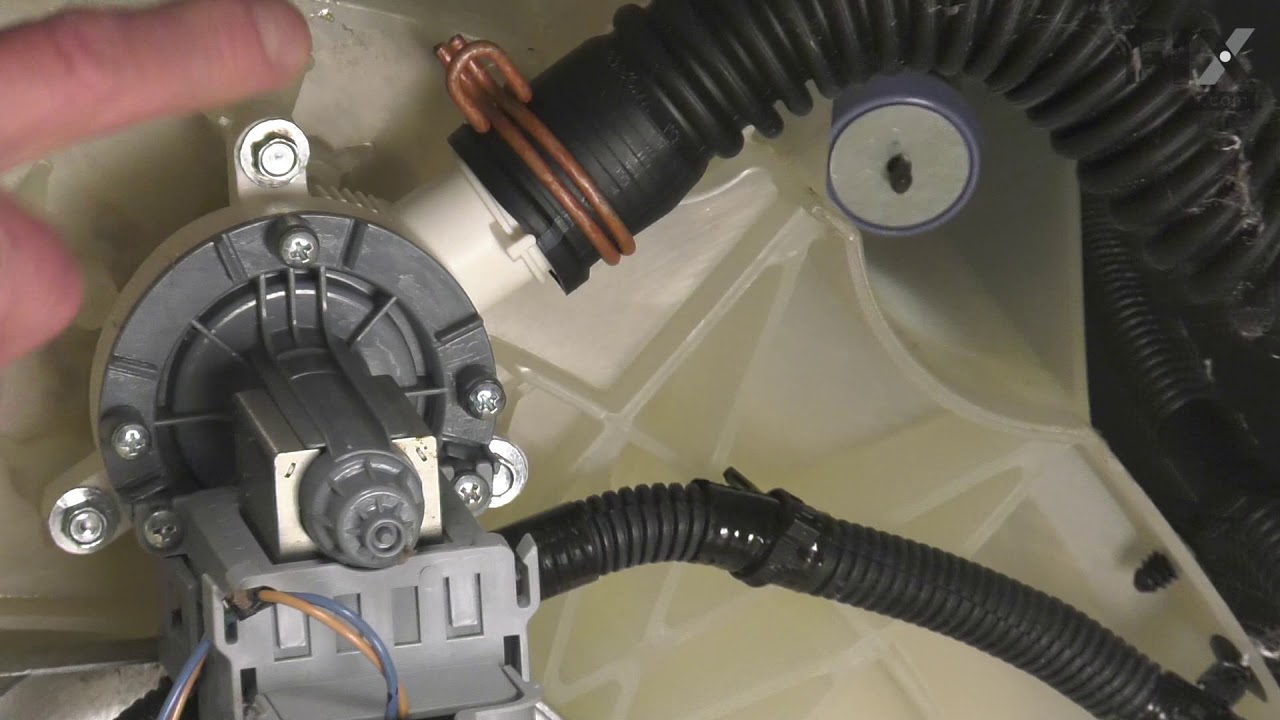

This pump helps expel water from the washing machine and is activated after the spin speed is maintained for a specific period of time

In Stock

Order within the next 3 hrs and your part ships today!

In Stock

Order within the next 3 hrs and your part ships today!

In Stock

Order within the next 3 hrs and your part ships today!

In Stock

Order within the next 3 hrs and your part ships today!

In Stock

Order within the next 3 hrs and your part ships today!

Questions and Answers

We're sorry, but our Q&A experts are temporarily unavailable.

Please check back later if you still haven't found the answer you need.

Common Problems and Symptoms for CAE2745FQ0

Viewing 8 of 8Leaking

Fixed by these parts

How to fix it

Will not agitate

Fixed by these parts

How to fix it

Will not drain

Fixed by these parts

How to fix it

Will Not Start

Fixed by these parts

How to fix it

Lid or door won’t close

Fixed by these parts

How to fix it

Spins slowly

Fixed by these parts

How to fix it

Spinning Issues

Fixed by these parts

How to fix it

Burning smell

Fixed by these parts

How to fix it

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

- Customer:

- Michelle from Richardson, TX

- Parts Used:

- 72017

- Difficulty Level:

- Really Easy

- Total Repair Time:

- Less than 15 mins

Scratches in Surface

This product comes in a bottle with a brush like Liquid Paper. It goes on incredibly easy. A second coat might be needed. I wanted to prevent rust from setting in so I covered the scratches and dings. The paint is a little brighter since my washer is 10 years old but it still looks great.

Was this instruction helpful to you?

Thank you for voting!

- Customer:

- David from BLOOMINGTON, IN

- Parts Used:

- W10721967

- Difficulty Level:

- Easy

- Total Repair Time:

- 30 - 60 mins

- Tools:

- Screw drivers, Socket set

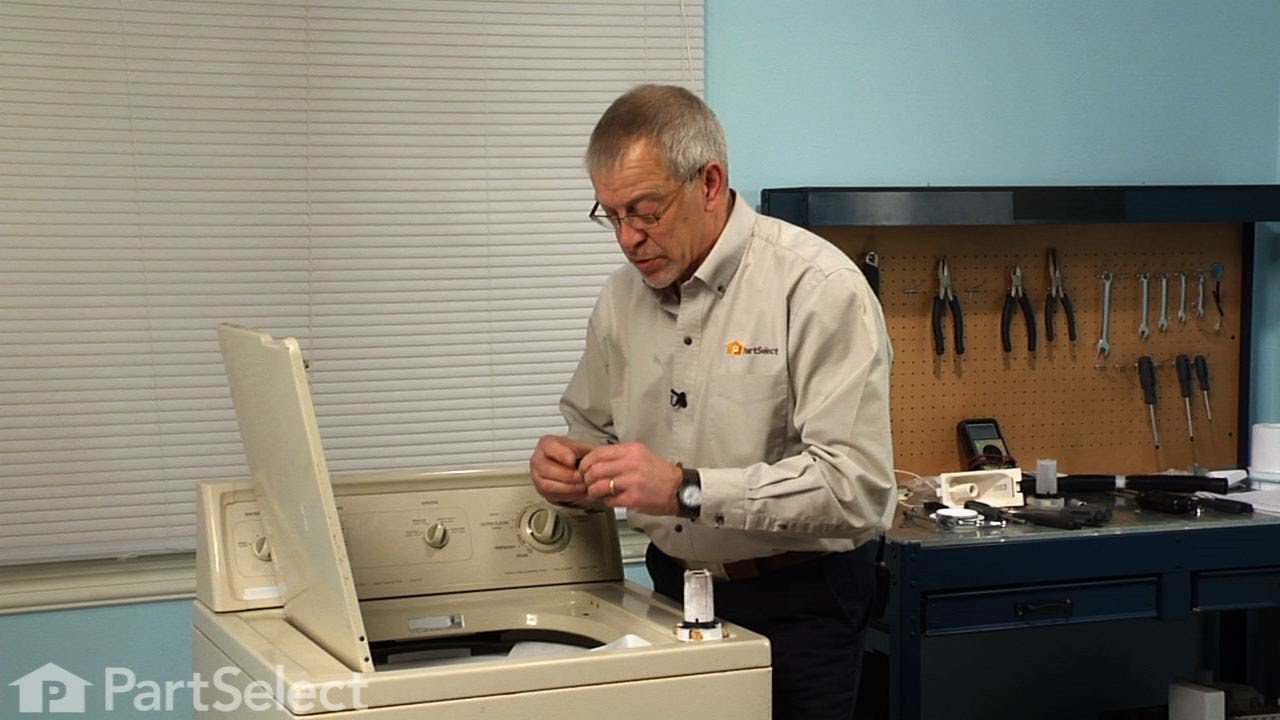

Noise, grinding sounds. Wash tub stopped turning but motor and cycles kept functioning. Process of elimination, must be the clutch assembly.

Easy, just followed the repair video. Recommend also ordering the drive belt. Bought one locally during my repair.

Was this instruction helpful to you?

Thank you for voting!

- Customer:

- David from EAST AMHERST, NY

- Parts Used:

- W10772621

- Difficulty Level:

- Easy

- Total Repair Time:

- 15 - 30 mins

- Tools:

- Socket set

washer not agitating

This was a learning experience but it appears to have worked out in the end. Our 3 1/2 year old washer was not agitating much and I attributed that to a loose bolt. I would tighten the bolt and it would work ok for a load or two and then stop agitating. I would find that the bolt was loose again. I took a number of steps to try to get

... Read more

the bolt to stay on tight - threadlock, a new bolt, more threadlock, and applying progressively more force on the bolt, with no better results. Yet the repair guys on you tube were saying the bolt only needs to be snug, not super tight - something was amiss. I even went so far as to secure the basket with a rope so I could use two hands on the socket wrench (please don't do this). But when I tried the washer again there was no agitation at all! I observed the agitation output in manual test mode and the bolt was turning in lock step with the shaft but the agitator wasn't turning at all. That's when I suspected that the problem was actually a worn lower agitator. Trouble was that now I couldn't seem to get the bolt off. Turning the wrench caused the shaft itself to rotate so I couldn't loosen the bolt from the shaft. I thought I broke the washer. Then I considered that maybe the shaft was rotating because the washer was in an agitation mode when I turned it off. I went back into manual test mode, made the washer spin, then turned it off. Fortunately, this worked. The shaft was again stationary and, albeit with great difficulty, I got the bolt off.

I removed the agitator, and as a pro would have figured out long before, the ridges inside the top of the lower agitator were almost completely worn down. I realized then that the contact between these ridges and the splines on the shaft is what is supposed to cause the lower agitator to move with the shaft. The purpose of the bolt is just to keep the agitator in the correct position and from coming off the shaft. I had been trying to compensate for the worn agitator ridges by over-tightening the bolt, creating some contact at the top of the shaft. This would work for a little while, then the agitator would start slipping, and the slipping agitator was acting just like a wrench loosening the bolt (until my stupid rope trick, that is.)

So I ordered a new agitator (only the lower agitator was bad, but the price of an entire agitator isn't a lot more than just the lower part and I was reading that the upper agitator parts will wear over time) and another new bolt (because my repeated attempts to over-tighten the first one I ordered had split the rubber gasket apart and worn the bolt head).

The new agitator fit snugly on the splines of the shaft so I sensed no need to use excessive force on the bolt. Just an easy one-handed snug tightening with the socket wrench, using the other hand to hold the lower agitator. The washer is now working again.

I removed the agitator, and as a pro would have figured out long before, the ridges inside the top of the lower agitator were almost completely worn down. I realized then that the contact between these ridges and the splines on the shaft is what is supposed to cause the lower agitator to move with the shaft. The purpose of the bolt is just to keep the agitator in the correct position and from coming off the shaft. I had been trying to compensate for the worn agitator ridges by over-tightening the bolt, creating some contact at the top of the shaft. This would work for a little while, then the agitator would start slipping, and the slipping agitator was acting just like a wrench loosening the bolt (until my stupid rope trick, that is.)

So I ordered a new agitator (only the lower agitator was bad, but the price of an entire agitator isn't a lot more than just the lower part and I was reading that the upper agitator parts will wear over time) and another new bolt (because my repeated attempts to over-tighten the first one I ordered had split the rubber gasket apart and worn the bolt head).

The new agitator fit snugly on the splines of the shaft so I sensed no need to use excessive force on the bolt. Just an easy one-handed snug tightening with the socket wrench, using the other hand to hold the lower agitator. The washer is now working again.

Read less

Was this instruction helpful to you?

Thank you for voting!