Models

>

WF219ANW

WF219ANW (XAA-0001) Samsung Washer

Jump to:

Find Part by Name

Keep searches simple, eg. "belt" or "pump".

Diagrams for WF219ANW

Viewing 7 of 7Keep searches simple, eg. "belt" or "pump".

$181.80

This pump helps expel water from the washing machine and is activated after the spin speed is maintained for a specific period of time.

In Stock

In Stock

In Stock

In Stock

In Stock

In Stock

In Stock

In Stock

In Stock

In Stock

In Stock

$87.25

The thermistor monitors and helps regulator the water temperature in the washer.

In Stock

Questions and Answers

We're sorry, but our Q&A experts are temporarily unavailable.

Please check back later if you still haven't found the answer you need.

Common Problems and Symptoms for WF219ANW

Viewing 3 of 3Will not drain

Fixed by these parts

How to fix it

Lid or door won’t close

Fixed by these parts

How to fix it

Leaking

Fixed by these parts

How to fix it

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

- Customer:

- SCOTT from VERNAL, UT

- Parts Used:

- DC31-00054A

- Difficulty Level:

- Easy

- Total Repair Time:

- 30 - 60 mins

- Tools:

- Pliers, Screw drivers

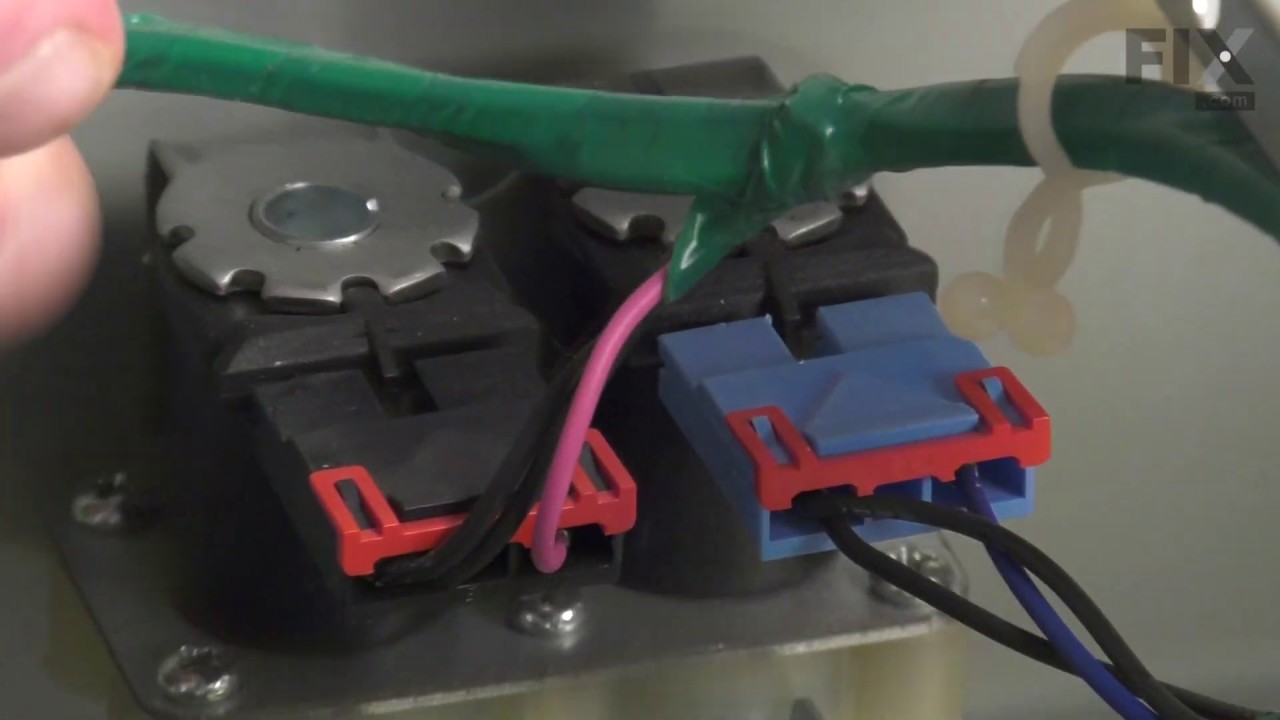

Code indicating washer was NOT discharging water

Watched the video, procedure was simple and as depicted on the video. Started by using a wet shop Vac to the discharge hose and sucked as much dirty wash water out as possible. Removed the pump,and found the motor did not turn freely. Removed the motor (3 screws) and replaced the motor with new part. Reassembled the washer, everything wor

... Read more

ked as it should. After about 3-4 loads of laundry, the "Not Draining" code / problem returned. Again, sucked out the water with the Shop Vac. Checked the Filter /Cleanout and found it completely packed with MUD. Cleaned that out, and again disassembled the washer. The pump was removed and the remaining muddy gunk was cleaned from the impeller. The 3 drain lines that attached to the pump were inspected for blockage/obstruction and flushed of any muddy residue. Reassembly was quick and easy, and the washer has worked well since. I have no idea how the dirt got into the system with enough dirt to gunk up the system. Recommend keeping more frequent inspections of the cleanout trap.

Read less

Was this instruction helpful to you?

Thank you for voting!

- Customer:

- Fredric from ROCKMART, GA

- Parts Used:

- DC96-01703B

- Difficulty Level:

- Really Easy

- Total Repair Time:

- 15 - 30 mins

- Tools:

- Pliers, Screw drivers

The water level was lower than normal.

First unplug or turn off thee circuit breaker. Then remove the two screws to the top cover. Slide the cover back about three inches then remove the cover. Next take out the screw to the old sensor. Then unplug the electrical connection by squeezing and the pulling to disengage. Now set the old unit aside. You then grad your eight inch wi

... Read more

re tie and hold the with flat side to the right and just to the right of the screw hole for the bracket is a square hole. Feed to wire tie into the square hole with your left hand then loop down left side of the end of new sensor and back up threw the square hole and tighten with the pliers. Your new sensor will be positioned just like it was mounted to the metal bracket. And pretty ridged. Now connect the vacuum hose and electrical connector.

Read less

Was this instruction helpful to you?

Thank you for voting!

- Customer:

- Nadira from JACKSONVILLE, FL

- Parts Used:

- DC64-00519B

- Difficulty Level:

- Very Easy

- Total Repair Time:

- 15 - 30 mins

- Tools:

- Screw drivers

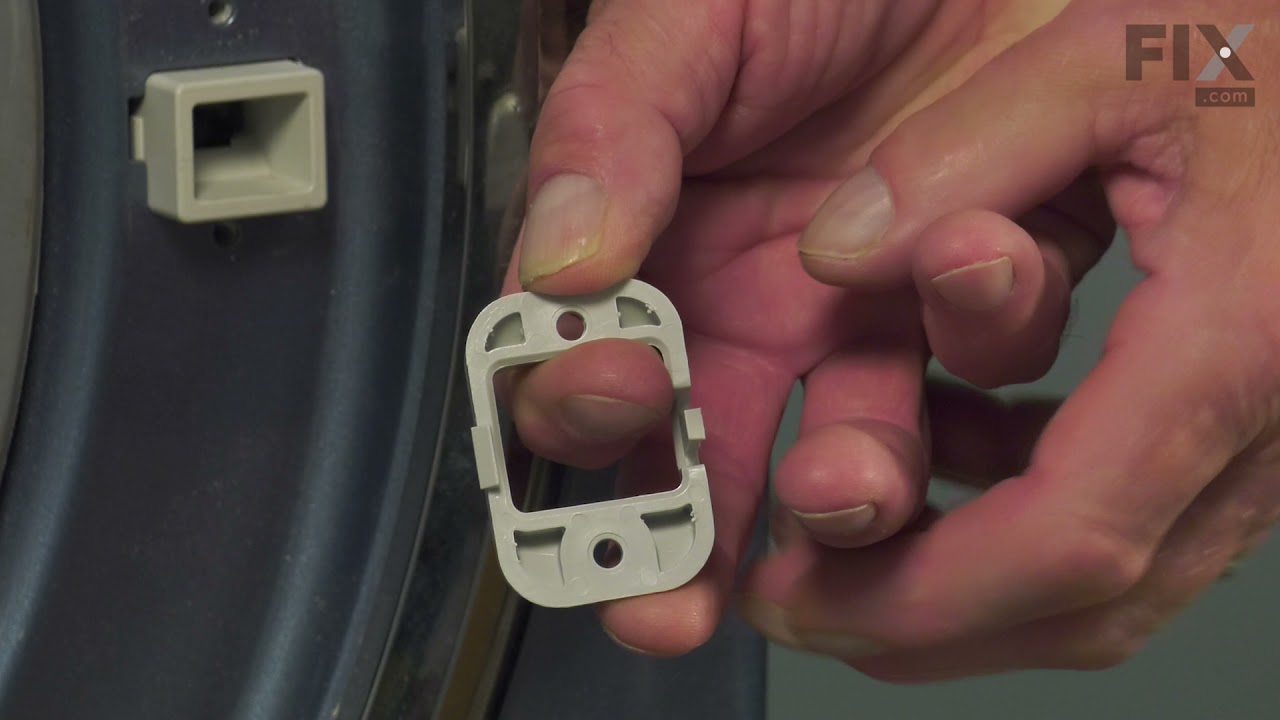

Front loader door would not lock.

Removed the rear top two Phillips screws, pull off top cover. Unscrew two phillips screws that hold the outside front lock trim, unclip (one left of housing) plastic housing. Remove one phillips screw 11 o'clock from housing, about 6" away, with door button above it, which releases the door lock housing from inside the machine. From right

... Read more

side (facing machine) look down into left front of machine, you will see a black cover, which does a goid job hiding the white part, but it protects the part from water, I guess. Unclip 3-4 plugs, push spinning loader away to pull out the complete part easily. Swap back covers (a bit annoying to place wiring harness back in such a tight place, and cover on. You can try another method if you have a simpler way, like place the harness onto part first, before plugging in and placing cover. But, I kept dropping the part into the machine, which equals a little pita). Then screw the 11pm screw to hold part and the two other screws (small housing and cover), place remaining 2 screws, and lid. Pretty much undo the above procedure. Done.

Read less

Was this instruction helpful to you?

Thank you for voting!