Models

>

WM0742HGA

WM0742HGA (APGEEUS) LG Washer

Jump to:

Find Part by Name

Keep searches simple, eg. "belt" or "pump".

Diagrams for WM0742HGA

Viewing 3 of 3Manuals & Guides for WM0742HGA

Click to downloadKeep searches simple, eg. "belt" or "pump".

$74.11

This is a drain pump motor assembly for washers. This OEM part is responsible for removing water from the washer during the drain part of the cycle. When this part is clogged, damaged or defective it ...

In Stock

Order within the next 7 hrs and your part ships today!

$26.80

The hot water valve is found at the back of your washer and controls the flow of hot water into the machine. If the valve is defective, the washer may leak, overfill, fill slowly, or not fill with wat...

In Stock

Order within the next 7 hrs and your part ships today!

In Stock

Order within the next 7 hrs and your part ships today!

$38.18

This hose has bellows to allow for flexibility during the wash and spin cycles.

In Stock

Order within the next 7 hrs and your part ships today!

$85.65

The door lock assembly is a genuine OEM part for your washing machine. This part informs the washer that the door is closed and locked in place, which allows the machine to start its cycle. If you are...

In Stock

Order within the next 7 hrs and your part ships today!

In Stock

Order within the next 7 hrs and your part ships today!

$38.18

This is a replacement sensor assembly for your washer. It may also be known as a motor rotor position sensor. The sensor assembly monitors the direction and speed of the spinning rotor and communicate...

In Stock

Order within the next 7 hrs and your part ships today!

$85.35

On a washer, this part is used for circulating the water. On a dishwasher, it is used for draining the water.

In Stock

Order within the next 7 hrs and your part ships today!

$214.57

This part is the replacement spider, or washer spinner support, for your washer. It is triangular, with three arms, and it is made of metal. The washer spinner supports and spins the tub or basket whi...

In Stock

Order within the next 7 hrs and your part ships today!

$14.48

The locking pin is used to hold the shock absorber on the washer. There is a pin used at the bottom and top of the shock absorber. Sold individually.

Special Order

$26.76

This replacement pump filter, also known as a filter assembly, is a genuine OEM part for your washer or washer/dryer combo. Before beginning this repair, turn off the power and water supply to your wa...

In Stock

Order within the next 7 hrs and your part ships today!

$8.04

This drain hose plug, also known as a hose cap, is a genuine OEM part for your washing machine. This plug caps the drain hose from the pump housing, and helps prevent leaks from your washer. Before be...

In Stock

Order within the next 7 hrs and your part ships today!

Questions and Answers

We're sorry, but our Q&A experts are temporarily unavailable.

Please check back later if you still haven't found the answer you need.

Common Problems and Symptoms for WM0742HGA

Viewing 16 of 16Will not drain

Fixed by these parts

How to fix it

Leaking

Fixed by these parts

How to fix it

Will Not Start

Fixed by these parts

How to fix it

Lid or door won’t close

Fixed by these parts

How to fix it

Will not agitate

Fixed by these parts

How to fix it

Draining Issues

Fixed by these parts

How to fix it

Not draining

Fixed by these parts

How to fix it

Engine runs but does not pump water

Fixed by these parts

How to fix it

Burning smell

Fixed by these parts

How to fix it

No hot or cold water

Fixed by these parts

How to fix it

Locking Issues

Fixed by these parts

How to fix it

Water Filling Issues

Fixed by these parts

How to fix it

Spinning Issues

Fixed by these parts

How to fix it

Noisy

Fixed by these parts

How to fix it

Spins slowly

Fixed by these parts

How to fix it

Noisy

Fixed by these parts

How to fix it

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

- Customer:

- Jorge from Apple Valley, CA

- Parts Used:

- 4681EA2001T

- Difficulty Level:

- Easy

- Total Repair Time:

- 1- 2 hours

- Tools:

- Screw drivers

Washing maching wouldn't drain

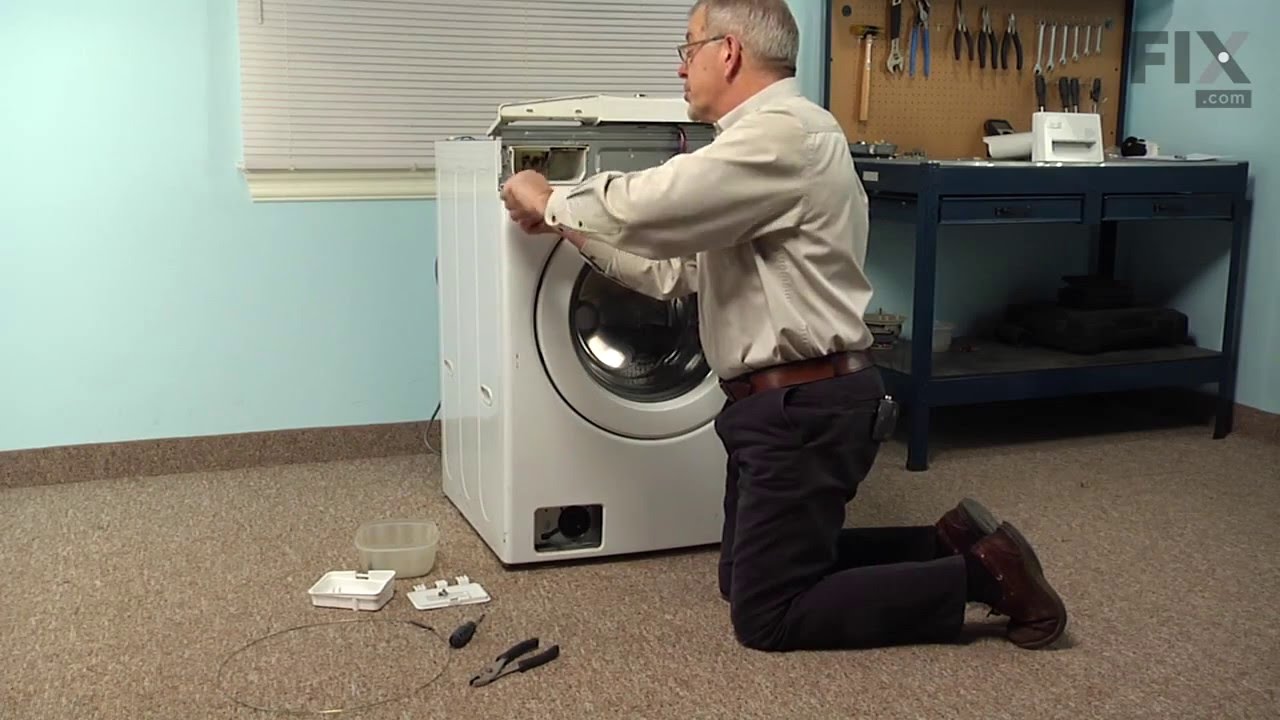

Removed the top of the washer by removing the 4 back screws and 2 small brackets. Then I removed the front panel, this was actually the hardest part, 2 screws and 8 tabs that you pop out carefully from the top of the panel. I only disconnected the power button and was able to rest the panel on top of the washer. The rest of the washer cam

... Read more

e apart quickly just moving down the front of the washer and removing the door, latch, tub gasket, drain cover. Removing the pump was just a mater of disconnecting the drain hoses, and one clip under the drain assembly. 3 screws attach the drain to assembly to the pump and only 2 wires that are clearly marked. Reassembly is just going back through in reverse order of disassenbly. The best thing about this is that it all comes apart with a standard phillips screwdriver.

Read less

Was this instruction helpful to you?

Thank you for voting!

- Customer:

- Mark from Harrisburg, PA

- Parts Used:

- 6501KW2002B

- Difficulty Level:

- Easy

- Total Repair Time:

- 30 - 60 mins

- Tools:

- Screw drivers, Socket set

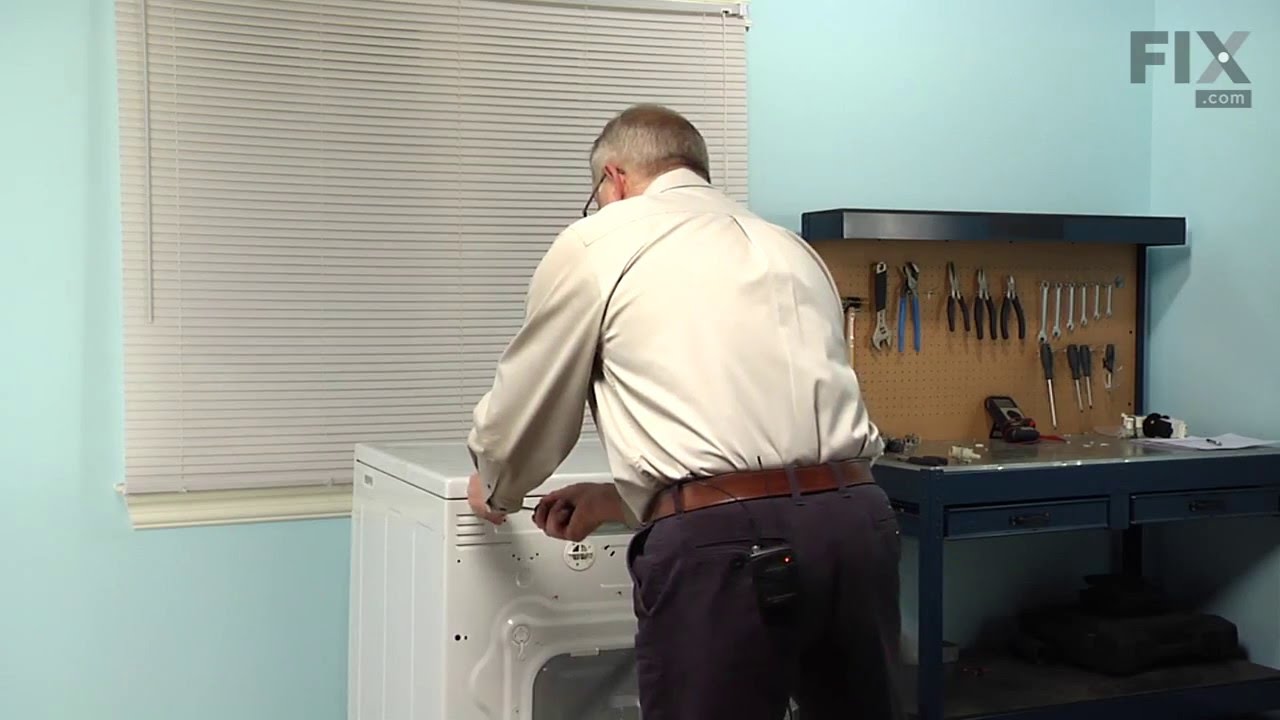

LE Error Message and won't spin drum properly

I first tested the motor per the service manual. I checked the resistance between the terminals of the 3 pin connector. It's supposed to be 5-15 ohms. The motor checked out so I replaced the main electrical board. It turns out that wasn't the problem. After a brief web search I found out that the hall sensor (which is attached to the

... Read more

motor stator) was the likely cause of the failure. I replaced that and everything works great now. And now I have a spare main board in case that ever fails. I also want to mention that I took the time to remove the dispenser box (where the water comes in and is directed to the different cleaning products) and cleaned it with a very strong bleach solution. It got rid of the mildew and funky smell. It seems that the fabric softener caused a lot of mildew to form inside the dispenser directly above the fabric softener tray. The bleach took care of that. This is probably something that should be done routinely to keep the mildew from forming.

Read less

Was this instruction helpful to you?

Thank you for voting!

- Customer:

- Anthony from Crystal Lake, IL

- Parts Used:

- 4036ER4001B, 383EER3001E

- Difficulty Level:

- Difficult

- Total Repair Time:

- More than 2 hours

- Tools:

- Pliers, Screw drivers, Socket set, Wrench (Adjustable), Wrench set

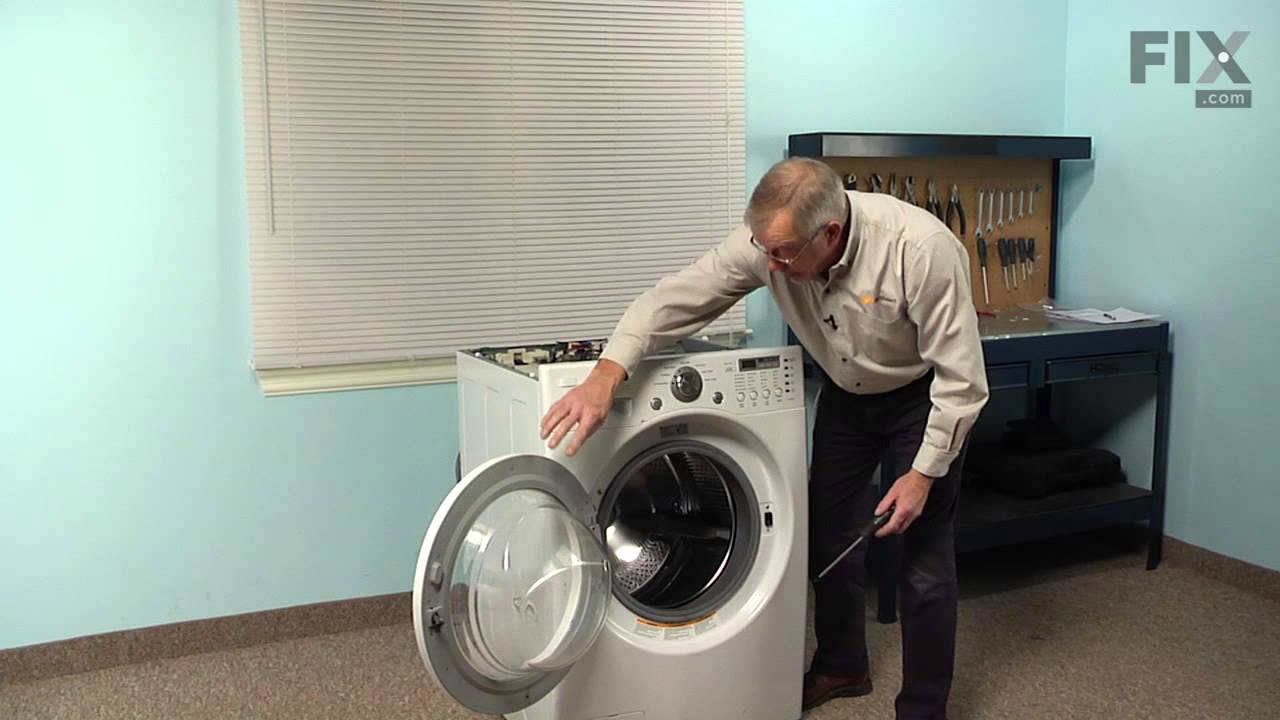

Worn bearings

To replace the bearings a complete disassembly of the washer was required. After pulling the tube assembly from the cabinet and separating the tube enclosure halves and removing the rotor and stator, since the washer uses direct drive, a gear puller was required to push the drive shaft through the old bearings since they didn’t separate e

... Read more

asily as seen in several YouTube videos. After removing the tube assembly it is recommended that you also separate from the spider, which contains the drive shaft, from the tube itself since a significant amount of sediment had caked inside the indentations on the inside of the spider. Since the front bearing, part number 4280FR4048D, was no longer available I used an NTN double sealed bearing, part number 6306LLUC3/L627. The only other tricky aspect of the repair was pushing the drive shaft through the new bearings since pushing it by hand did not produce enough force to get it through to expose enough of the shaft on the other side to be able to reconnect the rotor. The solution was to pull the shaft through rather than pushing it. To do this I placed a 1 3/4 inch drive socket over the outer ring of the rear bearing, and then I used a 3 inch 10mm x 1.50 mm bolt through the drive socket with enough large washers to use as spacers between the bolt head and the drive socket. I then threaded about a half inch of the bolt into the center of the drive shaft by hand to remove any gap between the bolt head and the washers. As I turned the bolt clockwise with a 17mm drive socket wrench the bolt pulled the drive shaft through the bearings with ease. I did follow the manufacturer’s recommendation to replace the seal between the two tube enclosure halves and the three dampers with new ones since they do eliminate much of the vibration during the spin cycle. I also replace the top bellows since I noticed that a large hole had been formed on it by rubbing against the inlet hoses which are situated directly above. The repair took a week only because I had to wait for parts.

Read less

Was this instruction helpful to you?

Thank you for voting!