Models

>

WCCB1030H1WC

WCCB1030H1WC General Electric Washer

Jump to:

Find Part by Name

Keep searches simple, eg. "belt" or "pump".

Diagrams for WCCB1030H1WC

Viewing 4 of 4Manuals & Guides for WCCB1030H1WC

Click to downloadKeep searches simple, eg. "belt" or "pump".

$9.61

This is a single tub dampening strap for a washer. It is recommended to replace all 4 tub dampening straps at the same time, to ensure even wear. This part supports the tub and minimizes vibration by ...

In Stock

Order within the next 1 hr and 13 mins and your part ships today!

$75.31

This is an authentic agitator for your washer, responsible for moving clothes inside the tub. Please note, it does not come with the fabric dispenser, so you will need to either transfer the old one t...

In Stock

Order within the next 1 hr and 13 mins and your part ships today!

This pump helps expel water from the washing machine and is activated after the spin speed is maintained for a specific period of time.

In Stock

Order within the next 1 hr and 13 mins and your part ships today!

$16.73

If your washer is leaking when it is filling or agitating, you may need to replace the tub seal. The tub seal is found between the transmission and the outer tub in your washing machine. This genuine ...

In Stock

Order within the next 1 hr and 13 mins and your part ships today!

$25.75

This is a 6-rib washer drive belt. It is sourced directly from the original manufacturer and constructed with a durable Poly V material. This part connects the drive motor to the drive system that tur...

In Stock

Order within the next 1 hr and 13 mins and your part ships today!

In Stock

Order within the next 1 hr and 13 mins and your part ships today!

In Stock

Order within the next 1 hr and 13 mins and your part ships today!

$27.53

The tub bearing secures the spin basket in the tub assembly of a washer. It is located on the bottom of the outer tub. A common symptom of a worn tub bearing is a very loud noise (including a grinding...

In Stock

Order within the next 1 hr and 13 mins and your part ships today!

$25.63

Bolt not included. This part connects the transmission drive shaft to the agitator base.

In Stock

Order within the next 1 hr and 13 mins and your part ships today!

$16.95

This replacement inlet drain hose connects your washer's water pump to its tub. This hose is seven and a half inches in length and only two inches wide.

In Stock

Order within the next 1 hr and 13 mins and your part ships today!

$12.61

This part is a replacement socket rod support for your washer. The socket rod support is found at the top of the washer frame in the front part of the washer. It supports the suspension rod, so the ro...

In Stock

Order within the next 1 hr and 13 mins and your part ships today!

$90.76

This part is the replacement inner tub base hub for your washer. It is made of metal and is approximately 15 inches in diameter. The inner tub base hub fits between the wash tub and the spin basket, a...

In Stock

Order within the next 1 hr and 13 mins and your part ships today!

Questions and Answers

We're sorry, but our Q&A experts are temporarily unavailable.

Please check back later if you still haven't found the answer you need.

Common Problems and Symptoms for WCCB1030H1WC

Viewing 8 of 8Leaking

Fixed by these parts

How to fix it

Will not drain

Fixed by these parts

How to fix it

Will not agitate

Fixed by these parts

How to fix it

Marks left on clothes

Fixed by these parts

How to fix it

Spins slowly

Fixed by these parts

How to fix it

Burning smell

Fixed by these parts

How to fix it

Shaking and Moving

Fixed by these parts

How to fix it

Noisy

Fixed by these parts

How to fix it

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

- Customer:

- Gerald from Midlothian, VA

- Parts Used:

- WH41X22935, WH23X10030

- Difficulty Level:

- Easy

- Total Repair Time:

- 30 - 60 mins

- Tools:

- Nutdriver, Pliers

Washing Machine was not draining water from tub.

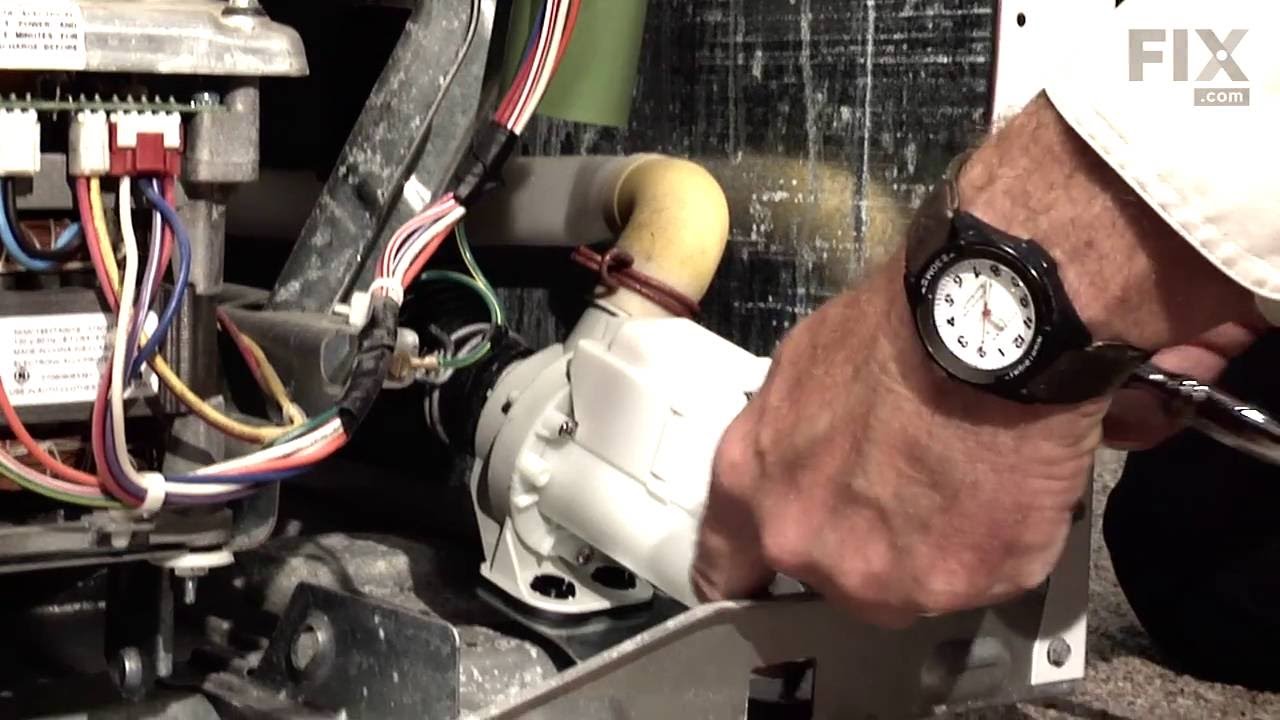

1. Drained the wash tub by taking the drain hose from the back of the washing machine and dropping it below the tub - water flowed out of hose a lot easier than trying to suck water out of tub using a pump (tried this on the first time I tried to fix washer). (Washing machine on 2nd floor of house and didn't want water running on floor)<

... Read more

br />2. Removed the 2 bolts holding the Pump/Motor assembly to the machine.

3. Removed both hose clamps on the Pump/Motor assembly and removed Pump.

4. Attached the new drain inlet hose to the pump and then to the tub with the original hose clamps.

5. Attached the drain hose to the pump and then plugged in the 2 wires for the pump.

6. Plugged in the washing machine and everything worked.

NOTES:

1. Hardest part was working with hose clamps (spring type clamps) in the tight space under the machine.

2. Easier to fix since I pulled machine apart a few days before - removing the clog in the pump/motor assembly only to get everything back together to find out that the motor was dead. Still well worth the time and effort due to not having to go out and buy a new Machine...

3. Removed both hose clamps on the Pump/Motor assembly and removed Pump.

4. Attached the new drain inlet hose to the pump and then to the tub with the original hose clamps.

5. Attached the drain hose to the pump and then plugged in the 2 wires for the pump.

6. Plugged in the washing machine and everything worked.

NOTES:

1. Hardest part was working with hose clamps (spring type clamps) in the tight space under the machine.

2. Easier to fix since I pulled machine apart a few days before - removing the clog in the pump/motor assembly only to get everything back together to find out that the motor was dead. Still well worth the time and effort due to not having to go out and buy a new Machine...

Read less

Was this instruction helpful to you?

Thank you for voting!

- Customer:

- douglas from danby, VT

- Parts Used:

- WH23X10030

- Difficulty Level:

- Easy

- Total Repair Time:

- 30 - 60 mins

- Tools:

- Socket set

machine would not drain all other functions seemed o.k

Aside from getting the wet clothes and most of the water out,the toughest part of the job for me was to figure out how to get inside the machine. I nearly wrecked the thing trying to lift the top panel. After some frustration I removed the star-type screws on back of the control panel and found, tucked away neatly, the documentation/parts

... Read more

list complete with instructions on how to remove the FRONT panel. Once I got inside it was easy to locate the pump. I ran the drain cycle for a moment to see if the pump turned at all. The original had an exposed fan so it was easy to see that indeed the motor was not turning. I inspected all the hose and electrical connections to make sure I had the tools I'd need and the savvy to replace the part(s) if I could locate them. I'm not much of a web-head, so I was a little surprised when I typed G.E. appliances and the search took me to partselect.com where I was pretty much coached through the procedure before I even ordered the part. The box arrived ahead of schedule (yay) and when I looked at the pump it didn't look much like the one I was replacing. But then I realized it was the same thing just ten years more advanced. I used a small pair of vise grips to pinch and lock the pipe clamps open. I know there is a plier made for this, but... Anyways, after loosening the clamps and sliding them away from the pump I pulled the hoses off and let the last of the rinse water still in them run down my shirt sleeve to my elbow. (optional, not recommended) Thus refreshed I then rummaged through my socket set and found what I needed to remove the 2 sheet metal mounting screws and disconnected the 2 power leads. I removed the faulty pump and proudly showed it to my wife. Unimpressed, she asked how much longer. I quickly reversed the procedure to install the new unit and confidently piled in a load of laundry. The cycle completed just fine and has done so since. I will and have recommmended partselect.com to friends and will use it again for sure.

Read less

Was this instruction helpful to you?

Thank you for voting!

- Customer:

- jon from barry, IL

- Parts Used:

- WH01X10302

- Difficulty Level:

- A Bit Difficult

- Total Repair Time:

- 15 - 30 mins

- Tools:

- Nutdriver

broken drive belt

To diagnose, first I unhooked the washer: power, water supply, and drain pipe. I then slid the washer out, laying it on its front. With nutdriver, I unscrewed two screws that held the other end of the drain tube and removed it completely. Then, again with the nutdriver removed 4 screws from the back near the legs, two in between the leg

... Read more

s in the middle, and approx. 4 to 6 on the bottom. This let me pull the bottom off partially to access the motor area. (I did did not take the bottom completely off, only about 2/3 off and let it bend over, as it was flexible tin) The belt was broken. After receiving the new belt, I positioned it between the pulley and the motor and between the drum and the big pulley. Then I rotated the big pulley, pulling the belt onto it as I rotated. At the same time, as I rotated, I pulled the other end of the belt on to the little pulley. Once it was on, I would put pressure on it as I turned the pulley, to jump the belt to the appropriate grooves on the little pulley. Note: the replacement belt had been modified, so it had one less groove than the pulley. I would have known this if I had read the insert that came with the belt first! Anyway, this was not a problem, only a design change. Also it was important to start the belt on the inside, so if it slipped, you didnt loose your bite. Total diagnostic, repair, and reassembly time: 30 minutes plus or minus. I had read other online forums that said you had to loosen the motor, etc. And I do know some type of a belt installation tool was offered on line, but I got along fine with my installation method. An extra set of hands would have been helpful, but not necessary.

Read less

Was this instruction helpful to you?

Thank you for voting!