Models

>

FWS6976FS1

FWS6976FS1 Frigidaire Washer

Jump to:

Find Part by Name

Keep searches simple, eg. "belt" or "pump".

Diagrams for FWS6976FS1

Viewing 6 of 6Manuals & Guides for FWS6976FS1

Click to downloadInstall

Installation Instructions

(0.19MB)

Care

Use and Care Manual

(0.12MB)

Wiring

Wiring Diagram

(0.36MB)

Keep searches simple, eg. "belt" or "pump".

$24.93

If your washer drum is not spinning, there may be an issue with your drive belt. The drive belt wraps around the motor pulley and helps the basket to spin. Other signs there are issues with the belt i...

In Stock

Order within the next 8 hrs and your part ships today!

In Stock

Order within the next 8 hrs and your part ships today!

In Stock

Order within the next 8 hrs and your part ships today!

This screw-in plastic leveling leg supports the washing machine. If your washer loses balance while it is tumbling, or makes loud noises, then it is best to replace the leveling leg to make sure the h...

In Stock

Order within the next 8 hrs and your part ships today!

$74.78

This seal helps prevent any leaking around the transmission of washing machines.

In Stock

Order within the next 8 hrs and your part ships today!

$11.21

This screw is designed to fit washers and dryers. Refer to the diagram provided by the manufacturer for further installation instructions and accurate application of screw in your tool.

In Stock

Order within the next 8 hrs and your part ships today!

In Stock

Order within the next 8 hrs and your part ships today!

$11.75

This is a screw and it is used with a variety of home appliances. It is less than 1/2 an inch long, and is #8-18 x 3/8. This part is a pan head, sheet metal, screw. It is made of metal.

In Stock

Order within the next 8 hrs and your part ships today!

Mounting bracket on this part replaces old style ( You may need to drill off old bracket before mounting new lock).

No Longer Available

In Stock

Order within the next 8 hrs and your part ships today!

In Stock

Order within the next 8 hrs and your part ships today!

Questions and Answers

We're sorry, but our Q&A experts are temporarily unavailable.

Please check back later if you still haven't found the answer you need.

Common Problems and Symptoms for FWS6976FS1

Viewing 9 of 9Leaking

Fixed by these parts

How to fix it

Will not agitate

Fixed by these parts

How to fix it

Burning smell

Fixed by these parts

How to fix it

Will not drain

Fixed by these parts

How to fix it

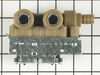

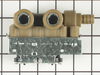

No hot or cold water

Fixed by these parts

How to fix it

Spins slowly

Fixed by these parts

How to fix it

Noisy

Fixed by these parts

How to fix it

Will Not Start

Fixed by these parts

How to fix it

Touchpad does not respond

Fixed by these parts

How to fix it

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

- Customer:

- rodney from fairfield bay, AR

- Parts Used:

- 134511600

- Difficulty Level:

- Really Easy

- Total Repair Time:

- 15 - 30 mins

- Tools:

- Screw drivers

replace broken drive belt

carefully pry up on front washer top to release plastic keeper pins,remove 2 phillips screws from beneath lower front washer panel,slightly lift upward on panel to release.remove old broken belt,push new belt beneath large tub pulley,put belt on small motor pulley,push back belt tension /idler arm,start belt on large tub pulley,turn tub p

... Read more

ulley by hand to run belt on,release tension on idler arm.replace front panel and lower top.WALAAH!!!! you are done.

Read less

Was this instruction helpful to you?

Thank you for voting!

- Customer:

- Rick from Walkerton, IN

- Parts Used:

- 5303279394, 131862900, 131545101, 131219900

- Difficulty Level:

- Really Easy

- Total Repair Time:

- 1- 2 hours

- Tools:

- Pliers, Screw drivers, Socket set

The primary problem was that the tub seal assembly was leaking.

1. I began by removing the two screws that hold the front panel in place. I then lifted the top free of the front panel and tilted it back to get it out of the way.

2. Using my fingers, I released the tabs that connect the tub cover to the tub. It took some effort to remove the cap("Mechanism") over the bolt connecting the ag ... Read more itator to the agitator drive block because I didn't want to break the tab. Once removed, I removed the bolt and the agitator. I then removed the two bolts that clamp the Trunnion to the agitator shaft.

3. It took a little more effort to remove the tub because of corrosion, however, by rocking the tub back and forth I was able to work it free and remove it. I then removed the bolts connecting the Trunnion to the tub. It took a hammer to remove the Trunnion from the tub, once again because of corrosion.

4. After removing the tub, the seal assembly was next and it was easy to remove. I cleaned the agitator shaft with steel wool before beginning the reassembly to remove the corrosion. Before installing the new seal, I lubricated the agitator shaft and the inside of the seal with a silicone grease that is normally used for water faucets. The seal installed easily although care was required to insure that the seal did not twist out of place when sliding it down the agitator shaft.

5. The rest of the reassembly went easily. Since my old filter on the bottom of the tub was clogged, I replaced it with a new one. It took a little time to get every tab on the filter aligned properly so that it could be rotated into place, but it went easily. Everything else reassembled with no problems.

6. It took considerable time to figure out how to replace the drive belt idler arm assembly because I could not figure out how to remove the pin that the idler arm pivots on. I finally reviewed the parts list on-line again and determined that there is a small C-clip that holds it together. Once I knew that. I was able to see the clip and remove it. From that point on, it was very easy to remove the old assembly and reinstall the new one. If I had to do it over again, I would have changed the sleeve at the same time that I changed the idler assembly because the assembly still wobbles on the pin more than I would like. However, it works fine so I won't worry about it until other repairs are needed.

The parts that I ordered from Parts Select were exact matches for the parts that I removed. They were in stock and were shipped the next business day. I would rate the repair as very easy.

2. Using my fingers, I released the tabs that connect the tub cover to the tub. It took some effort to remove the cap("Mechanism") over the bolt connecting the ag ... Read more itator to the agitator drive block because I didn't want to break the tab. Once removed, I removed the bolt and the agitator. I then removed the two bolts that clamp the Trunnion to the agitator shaft.

3. It took a little more effort to remove the tub because of corrosion, however, by rocking the tub back and forth I was able to work it free and remove it. I then removed the bolts connecting the Trunnion to the tub. It took a hammer to remove the Trunnion from the tub, once again because of corrosion.

4. After removing the tub, the seal assembly was next and it was easy to remove. I cleaned the agitator shaft with steel wool before beginning the reassembly to remove the corrosion. Before installing the new seal, I lubricated the agitator shaft and the inside of the seal with a silicone grease that is normally used for water faucets. The seal installed easily although care was required to insure that the seal did not twist out of place when sliding it down the agitator shaft.

5. The rest of the reassembly went easily. Since my old filter on the bottom of the tub was clogged, I replaced it with a new one. It took a little time to get every tab on the filter aligned properly so that it could be rotated into place, but it went easily. Everything else reassembled with no problems.

6. It took considerable time to figure out how to replace the drive belt idler arm assembly because I could not figure out how to remove the pin that the idler arm pivots on. I finally reviewed the parts list on-line again and determined that there is a small C-clip that holds it together. Once I knew that. I was able to see the clip and remove it. From that point on, it was very easy to remove the old assembly and reinstall the new one. If I had to do it over again, I would have changed the sleeve at the same time that I changed the idler assembly because the assembly still wobbles on the pin more than I would like. However, it works fine so I won't worry about it until other repairs are needed.

The parts that I ordered from Parts Select were exact matches for the parts that I removed. They were in stock and were shipped the next business day. I would rate the repair as very easy.

Read less

Was this instruction helpful to you?

Thank you for voting!

- Customer:

- alvaro from east hampton, NY

- Parts Used:

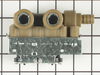

- 134190200

- Difficulty Level:

- Really Easy

- Total Repair Time:

- Less than 15 mins

- Tools:

- Pliers, Screw drivers

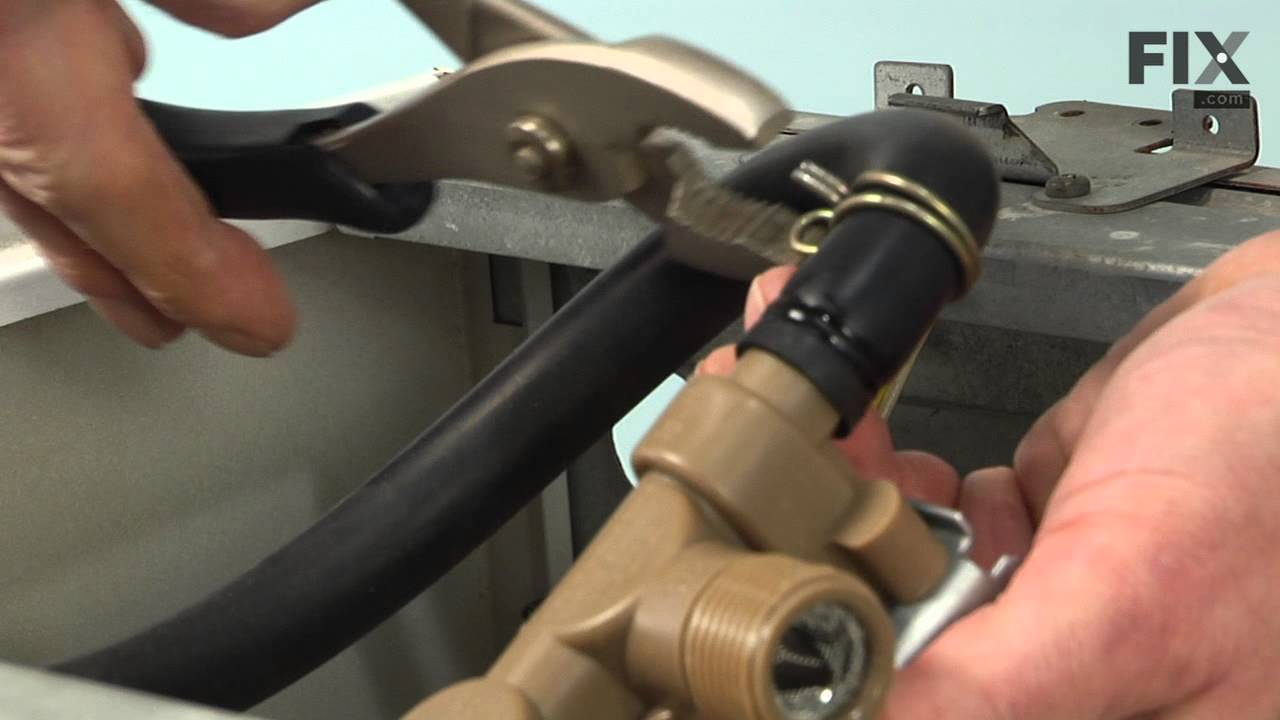

Washer Continued To Fill To Point Of Overflow

First I removed the top panel held by four screws at rear of panel, pulling the panel foward and up. Then disconnected the power and water connections. Then I removed the two screws holding the flow valve to the washer rear panel,pulled the valve foward ,removed the two electric connectors, pinched the water clamp with pliers and remo

... Read more

ved the water connection to the valve. Then replaced with the new valve followed the above steps in reverse order, finishing up by re placing the water connections and power. Then checked fo proper replacenent and leaks before replacing top panel.

Read less

Was this instruction helpful to you?

Thank you for voting!