Models

>

WLXG42RED1

WLXG42RED1 Westinghouse Washer Dryer Combo

Jump to:

Find Part by Name

Keep searches simple, eg. "belt" or "pump".

Diagrams for WLXG42RED1

Viewing 8 of 8Manuals & Guides for WLXG42RED1

Click to downloadKeep searches simple, eg. "belt" or "pump".

$62.48

This ball-and-socket style bearing kit is used in your dryer to support the rear of the drum as it tumbles through the dry cycle. The bearing attaches on the inside of the rear panel of the dryer cabi...

In Stock

$34.80

If your dryer is noisy while tumbling, you may need to replace the drum glides. This genuine OEM part is found attached to the front panel of your dryer. It is used to reduce friction and allows the d...

In Stock

$6.33

The drum support bearing is an authentic OEM replacement part for your dryer. The bearing is used to support the drum and allow it to rotate smoothly and quietly. If your dryer is excessively noisy wh...

In Stock

$24.93

If your washer drum is not spinning, there may be an issue with your drive belt. The drive belt wraps around the motor pulley and helps the basket to spin. Other signs there are issues with the belt i...

In Stock

In Stock

$51.85

This dryer lint screen is for laundry centers.

Dryer lint screen captures lint and debris from the exhaust air flowing from the dryer.

Follow the instructions in the owner's manual when installing this part.

In Stock

In Stock

$62.67

This door catch is an authentic OEM replacement part for your dryer. This part holds the door strike and ensures that the door stays closed while your dryer is running. This prevents hot air or laundr...

In Stock

In Stock

$21.45

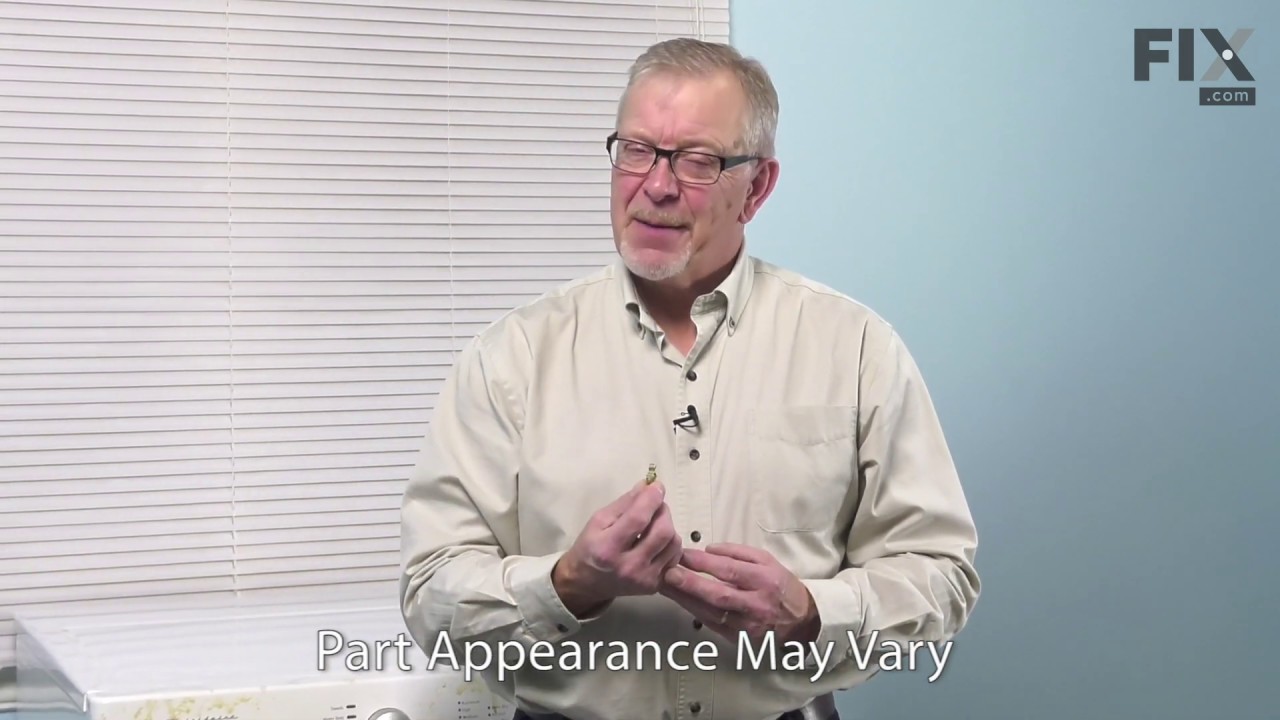

This coil ignition kit is used in dryers to open the gas valve when the dryer is on. This kit includes two coils. One is a two-wire secondary coil and the other is a three-wire booster coil. If your d...

In Stock

$10.64

This drum bearing bracket is for dryers. Drum bearing bracket holds and supports the drum bearing

In Stock

In Stock

Questions and Answers

We're sorry, but our Q&A experts are temporarily unavailable.

Please check back later if you still haven't found the answer you need.

Common Problems and Symptoms for WLXG42RED1

Viewing 13 of 13Noisy

Fixed by these parts

How to fix it

Marks left on clothes

Fixed by these parts

How to fix it

Door won’t close

Fixed by these parts

How to fix it

Leaking

Fixed by these parts

How to fix it

Will not agitate

Fixed by these parts

How to fix it

Burning smell

Fixed by these parts

How to fix it

Will not drain

Fixed by these parts

How to fix it

No hot or cold water

Fixed by these parts

How to fix it

Spins slowly

Fixed by these parts

How to fix it

Will Not Start

Fixed by these parts

How to fix it

Drum Not Spinning

Fixed by these parts

How to fix it

Not Heating

Fixed by these parts

How to fix it

Touchpad does not respond

Fixed by these parts

How to fix it

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

- Customer:

- Frank from Boyertown, PA

- Parts Used:

- 5303281153

- Difficulty Level:

- Easy

- Total Repair Time:

- 15 - 30 mins

- Tools:

- Nutdriver, Screw drivers

Loud Squeaking

1. Unplug dryer from outlet

2. Using Lg. flat screwdriver, pry under the front edge of the top and release two spring tabs

3. Lift up top and tilt back out of your way

4. Unscrew two phillips scews on inside of front panel

5. Lift up and out the front panel. Two spring clips at bottom.

6. Rlease tension on drum be ... Read more lt at the motor. Access panel at rear of dryer.

7.Unscrew 3 screws from inside, center rear of drum.

8. Remove drum through the front of the dryer. You may have to spread the sides apart a little bit for it to fit

9. Lift up on the rear drum bearing to remove it from the bearing retainer. ( U shaped plastic socket)

10. unsrew 2 screws and remove the bearing retainer, ground ball. Ball retainer is on outside of dryer.

11. Vacuum everything--duct, blower, lint trap, ect.

12. Intall new bearing retainer and grounding ball, an assistant is helpful at this time, one to hold ball retainer on rear of dryer, one to screw it in from the inside

13. reassemble remainder of parts in reverse order.

2. Using Lg. flat screwdriver, pry under the front edge of the top and release two spring tabs

3. Lift up top and tilt back out of your way

4. Unscrew two phillips scews on inside of front panel

5. Lift up and out the front panel. Two spring clips at bottom.

6. Rlease tension on drum be ... Read more lt at the motor. Access panel at rear of dryer.

7.Unscrew 3 screws from inside, center rear of drum.

8. Remove drum through the front of the dryer. You may have to spread the sides apart a little bit for it to fit

9. Lift up on the rear drum bearing to remove it from the bearing retainer. ( U shaped plastic socket)

10. unsrew 2 screws and remove the bearing retainer, ground ball. Ball retainer is on outside of dryer.

11. Vacuum everything--duct, blower, lint trap, ect.

12. Intall new bearing retainer and grounding ball, an assistant is helpful at this time, one to hold ball retainer on rear of dryer, one to screw it in from the inside

13. reassemble remainder of parts in reverse order.

Read less

Was this instruction helpful to you?

Thank you for voting!

- Customer:

- rodney from fairfield bay, AR

- Parts Used:

- 134511600

- Difficulty Level:

- Really Easy

- Total Repair Time:

- 15 - 30 mins

- Tools:

- Screw drivers

replace broken drive belt

carefully pry up on front washer top to release plastic keeper pins,remove 2 phillips screws from beneath lower front washer panel,slightly lift upward on panel to release.remove old broken belt,push new belt beneath large tub pulley,put belt on small motor pulley,push back belt tension /idler arm,start belt on large tub pulley,turn tub p

... Read more

ulley by hand to run belt on,release tension on idler arm.replace front panel and lower top.WALAAH!!!! you are done.

Read less

Was this instruction helpful to you?

Thank you for voting!

- Customer:

- William from Boise, ID

- Parts Used:

- 5303937139

- Difficulty Level:

- Easy

- Total Repair Time:

- 15 - 30 mins

- Tools:

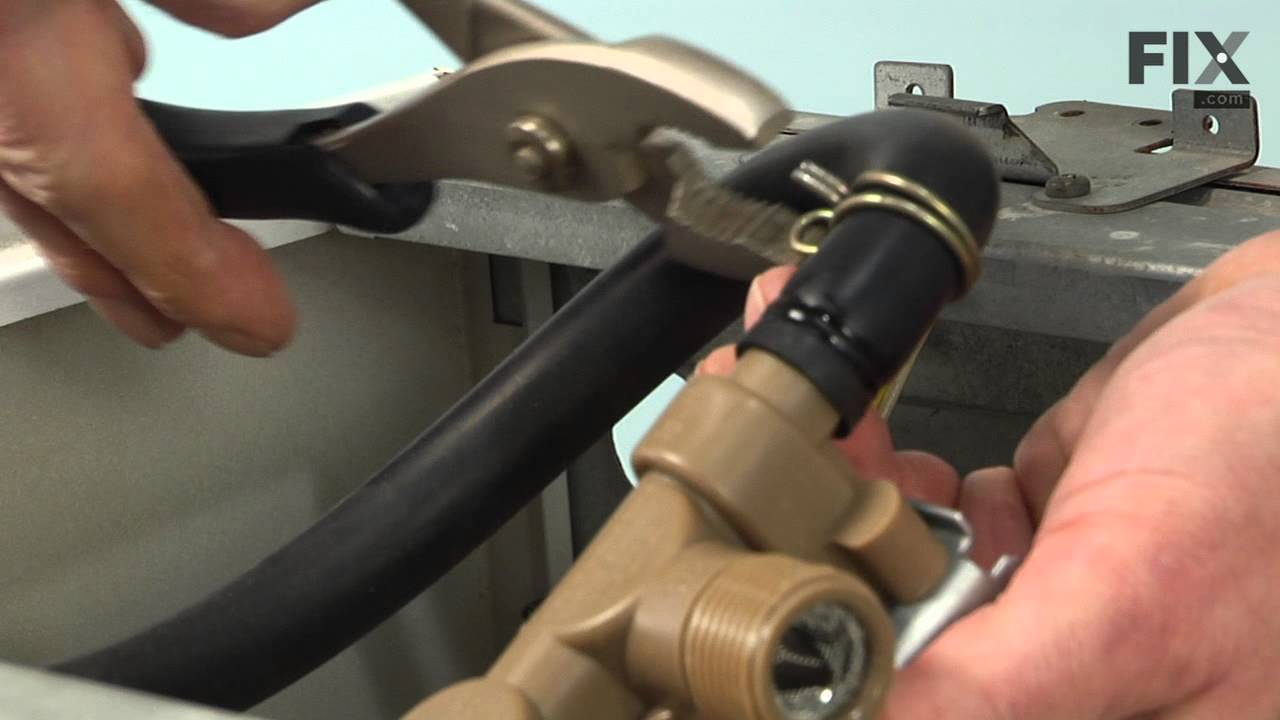

- Pliers, Screw drivers

Drum glide wore down and caused close to get stuck between drum and front panel.

Unpluged dryer. Removed the top of dryer by pushing in a retaining clip on both sides of the front lip with a screw driver. Remove the two screws on both sides of front panel. These screws are square head or phillips #2. Unplugged the wiring harness to front panel (make sure power has been disconnected). Support drum and lean front pa

... Read more

nel away from dryer body. Front panel will pull off of tabs at bottom. The old drum glide is fiberous and hard to remove. I removed most of it with the pliers, but had to carefully scrape the balance of the glide off with the wood chisel. The adhesive that comes with the repair part has an acetone base, so I used acetone (or you could use nail polish remover) to remove the old adhesive. Once the acetone has dried, I applied an 1/8" snaking bead of adhesive to the front panel. There is more adhesive in the tube than you need so do not use too much. Make sure that you get adhesive as close to the base of the lower seal as you can. Follow directions on adhesive tube and then attach the glide. I let it set up for about 30 seconds. Place the front panel back on the tabs of the dryer. Carefully lift the drum an fit it on the front panel and insert the two screws holding the panel to the base. Reconnect the wiring harness and make sure it is not in contact with the drum. Check to make sure that all of the electrical connectors on the timer are still in place. Reassemble the dryer. Reconnect power.

Read less

Was this instruction helpful to you?

Thank you for voting!