Models

>

WSM2420TAZAA

WSM2420TAZAA General Electric Washer Dryer Combo

Jump to:

Find Part by Name

Keep searches simple, eg. "belt" or "pump".

Keep searches simple, eg. "belt" or "pump".

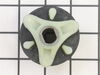

$27.87

This is an OEM direct drive motor coupling, which provides a cushioned connection between the transmission and the motor shaft. This is the newer version of this part, made with new metal sleeves for ...

In Stock

In Stock

$133.26

Used with washer/dryer combos. This part makes sure that the lid is shut before allowing the machine to start or agitate.

In Stock

$61.67

This fuse is made to trip at a higher temperature than the high limit thermostat. When this fuse trips, it will no longer work. You must replace it.

In Stock

In Stock

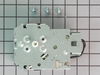

$288.95

The timer controls most of the operations of the washer: water level, tub filling and emptying, length of cycles, and cycle setting sequences.

In Stock

In Stock

In Stock

These parts help keep the washer from vigorous shaking during its cycles.

No Longer Available

In Stock

Special Order

Questions and Answers

We're sorry, but our Q&A experts are temporarily unavailable.

Please check back later if you still haven't found the answer you need.

Common Problems and Symptoms for WSM2420TAZAA

Viewing 9 of 9Will not agitate

Fixed by these parts

How to fix it

Spins slowly

Fixed by these parts

How to fix it

Will not drain

Fixed by these parts

How to fix it

Burning smell

Fixed by these parts

How to fix it

Will Not Start

Fixed by these parts

How to fix it

Spinning Issues

Fixed by these parts

How to fix it

Leaking

Fixed by these parts

How to fix it

Noisy

Fixed by these parts

How to fix it

Touchpad does not respond

Fixed by these parts

How to fix it

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

- Customer:

- Jeff from Wayne, NJ

- Parts Used:

- 285753A

- Difficulty Level:

- Easy

- Total Repair Time:

- 30 - 60 mins

- Tools:

- Pliers, Screw drivers, Socket set

No movement from Basket & agitator

The job looked intimidating but turned out to be very easy.

First take off the water pump by removing the two clips that hold it in place. Place a shallow pan under the pump to catch the water that is in the pump and hoses. Open the hose clamps with a pair of pliers or channel locks (better) and slide the hoses off of the water pum ... Read more p.

The motor comes off next. Unplug the electrical connector from the motor and two wires from the capacitor. Remove the two screws holding the clamps in place and then pop off the two clamps. You will need to hold up the motor with one hand while you remove the clamps or it will fall to the floor once the clamps are removed.

One piece of the coupling assemble will be attached to the motor and the other will be attached to the gearcase drive shaft. If you want to clean up the mess created by the shredded rubber center piece of the coupling assembly you will have to take off the motor mounting plate. It is held on by two bolts and removing it makes installing the coupling easier but probably not necessary.

Push the back half of the coupling on to the gearcase drive shaft until the shaft is flush with the face of the coupling. Install the new rubber center piece on to the coupling then re-install the motor mounting plate. Install the other half of the coupling on to the motor shaft and lift the motor up to the coupling. You have to rotate the motor shaft by spinning the fan blades until the coupling lines up so you can slide it into the other half of the coupling. Then just reattach the motor, connectors and water pump in the reverse order of disassembly.

First take off the water pump by removing the two clips that hold it in place. Place a shallow pan under the pump to catch the water that is in the pump and hoses. Open the hose clamps with a pair of pliers or channel locks (better) and slide the hoses off of the water pum ... Read more p.

The motor comes off next. Unplug the electrical connector from the motor and two wires from the capacitor. Remove the two screws holding the clamps in place and then pop off the two clamps. You will need to hold up the motor with one hand while you remove the clamps or it will fall to the floor once the clamps are removed.

One piece of the coupling assemble will be attached to the motor and the other will be attached to the gearcase drive shaft. If you want to clean up the mess created by the shredded rubber center piece of the coupling assembly you will have to take off the motor mounting plate. It is held on by two bolts and removing it makes installing the coupling easier but probably not necessary.

Push the back half of the coupling on to the gearcase drive shaft until the shaft is flush with the face of the coupling. Install the new rubber center piece on to the coupling then re-install the motor mounting plate. Install the other half of the coupling on to the motor shaft and lift the motor up to the coupling. You have to rotate the motor shaft by spinning the fan blades until the coupling lines up so you can slide it into the other half of the coupling. Then just reattach the motor, connectors and water pump in the reverse order of disassembly.

Read less

Was this instruction helpful to you?

Thank you for voting!

- Customer:

- Hugo from Frisco, TX

- Parts Used:

- 285753A

- Difficulty Level:

- Really Easy

- Total Repair Time:

- 30 - 60 mins

- Tools:

- Pliers, Screw drivers, Socket set

Broken Coupling

Very easy -

1. Removed hoses from the pump

2. Removed Wiring harness from the motor

3. Unscrewed saftey screws from both clamps which hold the motor against the motor bracket.

4. Using a screw driver I easily removed/pryed the clamps from the motor.

5. I then removed the broken plastic coupler from the motor sha ... Read more ft and installed the new one coupler.

6. I did the same thing on the clutch side.

7. I set the Rubber coupler in clutch side.

8. Put motor back on until couplers joined together.

9. Placed Brackets back on Motor (patience here).

10. screwed back saftey screws on clamps.

11. connected hoses back.

Thats it... 45 minutes at most .. Save me from having to buy a new easher. I was convinced I was going to have too until I peeked underneatch the washer and saw the rubber coupler on the ground...

1. Removed hoses from the pump

2. Removed Wiring harness from the motor

3. Unscrewed saftey screws from both clamps which hold the motor against the motor bracket.

4. Using a screw driver I easily removed/pryed the clamps from the motor.

5. I then removed the broken plastic coupler from the motor sha ... Read more ft and installed the new one coupler.

6. I did the same thing on the clutch side.

7. I set the Rubber coupler in clutch side.

8. Put motor back on until couplers joined together.

9. Placed Brackets back on Motor (patience here).

10. screwed back saftey screws on clamps.

11. connected hoses back.

Thats it... 45 minutes at most .. Save me from having to buy a new easher. I was convinced I was going to have too until I peeked underneatch the washer and saw the rubber coupler on the ground...

Read less

Was this instruction helpful to you?

Thank you for voting!

- Customer:

- Roger from Swainsboro, GA

- Parts Used:

- 285753A

- Difficulty Level:

- Really Easy

- Total Repair Time:

- 15 - 30 mins

- Tools:

- Screw drivers, Socket set

Wouldn't agitate or spin.

First, I removed two screws holding the bottom fiberboard panel in place, and the panel, to gain access to the motor, transmission, and pump. Unfortunately, I had the machine tilted to the front, and didn't have room to release the pump. I had to set the machine back up, and get manuvered around so I could lay it on it's back (I was worki

... Read more

ng in the confines of a small laundry room). Once on it's back, I released the two clips holding the pump with a flat head screwdriver, lifted it up and out of the way without having to disconnect any of the piping, then I released the two clips holding the motor, again with a flathead screwdriver, disconnected the wiring plugs, and capacitor wires, then lifted the motor up and out of the machine. I then removed the two bolts holding the motor mounting plate to the transmission. Then, again using a large flat head screwdriver, I pried the transmission coupling half off the transmission shaft, I had to work it up, while turning the shaft, and then the same for the motor half. I then wiped off both shafts, and gently tapped both coupling halves back onto the shafts,

( this is easier using a socket that is just large enough to go over the shafts). Then I reinstalled the motor mounting plate, slipped the rubber coupling onto the transmission coupling half, lifted the motor into place, and rotated from the pump end to line up with the remaining holes on the rubber coupling. I then reinstalled the clips used to hold the motor in place, reinstallation only took thumb pressure to snap back into place, then, I reinstalled the pump, using the same method, and reconnected the wiring plugs and copacitor leads. Lastly, I reinstalled the fiberboard panel into the bottom, and set the machine upright, slid back into place, and reconnected the hoses and electrical, and tested the machine. Worked perfectly.

In actually took longer to disconnect the machine, and get it out and back in, than it did to replace the coupling.

( this is easier using a socket that is just large enough to go over the shafts). Then I reinstalled the motor mounting plate, slipped the rubber coupling onto the transmission coupling half, lifted the motor into place, and rotated from the pump end to line up with the remaining holes on the rubber coupling. I then reinstalled the clips used to hold the motor in place, reinstallation only took thumb pressure to snap back into place, then, I reinstalled the pump, using the same method, and reconnected the wiring plugs and copacitor leads. Lastly, I reinstalled the fiberboard panel into the bottom, and set the machine upright, slid back into place, and reconnected the hoses and electrical, and tested the machine. Worked perfectly.

In actually took longer to disconnect the machine, and get it out and back in, than it did to replace the coupling.

Read less

Was this instruction helpful to you?

Thank you for voting!