Models

>

SST25CE

SST25CE Weed Eater Trimmer

Jump to:

Find Part by Name

Keep searches simple, eg. "belt" or "pump".

Diagrams for SST25CE

Viewing 2 of 2Keep searches simple, eg. "belt" or "pump".

$4.99

This fuel filter is for lawn and garden equipment engines.

Fuel filter cleans the fuel before it reaches the carburetor.

Work in a well-ventilated area when installing this part. Drain the fuel...

In Stock

Order within the next 9 hrs and your part ships today!

$6.62

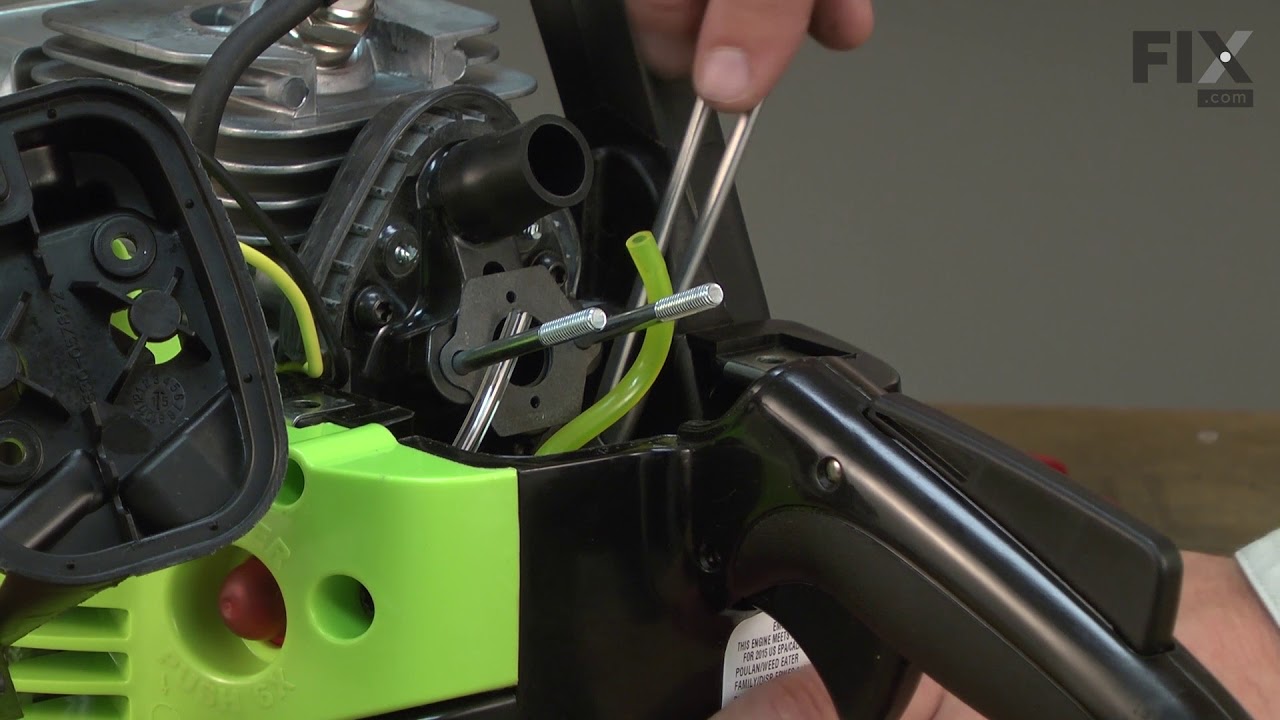

This chainsaw fuel line kit carries fuel from the tank into the carburetor and from the primer bulb to the fuel system. This part is mostly used on gas trimmers and blowers. The fuel lines are made fr...

In Stock

Order within the next 9 hrs and your part ships today!

$6.21

This is a tank purge line, also known as a fuel line kit, and it is used with various lawn equipment. The line connects fuel from the tank into the carburetor, and from the primer bulb back into the f...

In Stock

Order within the next 9 hrs and your part ships today!

This is a spark plug for your lawn equipment. This part ignites the air and fuel mixture in the cylinder of the engine to power your machine. If the tip of the spark plug is burnt out or damaged it is...

No Longer Available

In Stock

Order within the next 9 hrs and your part ships today!

$17.43

This fuel tank is for lawn and garden equipment engines.

Fuel tank holds the gas that's needed by the engine.

Work in a well-ventilated area when installing this part. Drain the existing fuel f...

In Stock

Order within the next 9 hrs and your part ships today!

On Order

In Stock

Order within the next 9 hrs and your part ships today!

In Stock

Order within the next 9 hrs and your part ships today!

In Stock

Order within the next 9 hrs and your part ships today!

In Stock

Order within the next 9 hrs and your part ships today!

Questions and Answers

We're sorry, but our Q&A experts are temporarily unavailable.

Please check back later if you still haven't found the answer you need.

Common Problems and Symptoms for SST25CE

Viewing 2 of 2Will Not Start

Fixed by these parts

How to fix it

Engine stops after a few seconds or minutes

Fixed by these parts

How to fix it

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Weak spark. Multiple fuel leaks/ no start.

Pull #25 torx 4mm screws until you find the ignition module. Replace it, use lock tight, gap with a paper credit card. Reassemble. Replace cap and fuel lines. Pump and pull till it blows the carb cleaner and Blaster out and starts.

Was this instruction helpful to you?

Thank you for voting!

Both the Fuel line and the Engine fuel line, where dry rotted.

1) While still attached to the fuel tank, I first sized up the old fuel lines with the newer fuel lines.

2) With a pair of needle nose players, I then removed the old dry rotted fuel ?? lines, from the fuel tank.

3) I cleaned the fuel tank and around the carburetor area, to insure that there was no debris, that could possibly fa ... Read more ll into the path of the new fuel lines installation.

4) I then installed the smaller one of the fuel lines, so that it would be out of the way, of the larger fuel line. I Pulled the fuel line through the smaller hole in the fuel tank, with needle nose players. I pulled the smaller fuel line out through the fuel tank filler hole, attached the fuel filter to the smaller fuel line. I Made sure that the fuel filter was extended to the furthest end of the fuel tank bottom. Six inches in all. I then attached the smaller fuel line to the carburetor.

5) I Installed the larger fuel line, followed the same procedures as the smaller fuel line.

6) Both fuel lines where cut on an angle for easy installation. No lubricant was necessary.

7) I filled up the fuel tank with fresh fuel and oil, new air filter and spark plug. It started on the first pull. Amazing.

2) With a pair of needle nose players, I then removed the old dry rotted fuel ?? lines, from the fuel tank.

3) I cleaned the fuel tank and around the carburetor area, to insure that there was no debris, that could possibly fa ... Read more ll into the path of the new fuel lines installation.

4) I then installed the smaller one of the fuel lines, so that it would be out of the way, of the larger fuel line. I Pulled the fuel line through the smaller hole in the fuel tank, with needle nose players. I pulled the smaller fuel line out through the fuel tank filler hole, attached the fuel filter to the smaller fuel line. I Made sure that the fuel filter was extended to the furthest end of the fuel tank bottom. Six inches in all. I then attached the smaller fuel line to the carburetor.

5) I Installed the larger fuel line, followed the same procedures as the smaller fuel line.

6) Both fuel lines where cut on an angle for easy installation. No lubricant was necessary.

7) I filled up the fuel tank with fresh fuel and oil, new air filter and spark plug. It started on the first pull. Amazing.

Read less

Was this instruction helpful to you?

Thank you for voting!

Fuel and Purge lines had disintegrated

Disassembled it and cleaned fuel tank. Cut and ran new fuel lines, installed filter and reassembled. Parts fit perfectly and got running after not running for over 20 years.

Was this instruction helpful to you?

Thank you for voting!