Models

>

JXT8036ADS

JXT8036ADS Jenn-Air Range Hood

Jump to:

Find Part by Name

Keep searches simple, eg. "belt" or "pump".

Diagrams for JXT8036ADS

Viewing 2 of 2Manuals & Guides for JXT8036ADS

Click to downloadKeep searches simple, eg. "belt" or "pump".

Questions and Answers

We're sorry, but our Q&A experts are temporarily unavailable.

Please check back later if you still haven't found the answer you need.

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

- Customer:

- Robert from Costa Mesa, CA

- Parts Used:

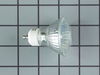

- 49001053

- Difficulty Level:

- A Bit Difficult

- Total Repair Time:

- 15 - 30 mins

- Tools:

- Pliers, Screw drivers

The range hood lights could not be turned OFF!

This turned out to be a two stage repair.

First attempt: Power off to hood. Removed the switch assembly thinking the problem was with the off/on button (two phillips screws and a gentle lift of the bracket to free the assembly). A sevice loop allowed me to lower the switch assembly and inspect the circuit board (CB) inside. ... Read more I tried to operate the switch directly on the CB (i.e. bypassing the button hoping it might be something mechanical with the button, but still could not turn the lights off. Believing the CB was bad, I ordered a new one.

Power off to hood. I installed the new CB but I still could not turn the hood lights off.

I then ordered the next higher assembly circuit board (looking at the PartsSelect.com drawing).

Second attempt: Received the new CB. Power off to the hood. Getting this CB down so that I could replace it was a problem, as it was higher up in the hood and was very space limited, and having to work upside down, looking up into the hood. I used a double ended phillips screwdrive with 90 deg bends on both ends for the four screws holding the cover on the housing with the CB inside. The screws were recessed in the cover. Once I got the head exposed, I used pliers to turn the screws out a bit faster. We're talking a quarter turn at a time here. Once the cover was off, I dopped the CB down using the service loop. I removed the old CB and installed the new one, carefully changing out each connection one at a time. This required the loosening of two very small terminal screws in a cconnection block mounted on the CB for the power lines .You need a very small good quality screwdriver that fits the screws good to get them loose, as they were very tight and it would be possible to damage the CB if you twisted the block on the board (be very careful here). There are also four other slip on connector and one multi-pinned connector (care required here also to avoid bending any of the very small pins). No soldering required. I tested the system with the CB dangling from the hood and everything worked. I put the CB back up in the housing, making sure the wires would not be pinched by the cover (which only goes on one way in order to "clamp" the wires in place), carefully put the cover in place, and put the four screws back in, I then tucked the service loop back up out of the way, and put the hood filters back in place.

Power back on and a final test.... All good.

One other thing. The CBs should be handled with care reqarding static discharge. Touching the hood and handling the boards by their edges is probably a good idea.

I hope this helps someone.

Thanks PartSelect. com

P.S. Any chance of returning the first CB which I didn't need?

First attempt: Power off to hood. Removed the switch assembly thinking the problem was with the off/on button (two phillips screws and a gentle lift of the bracket to free the assembly). A sevice loop allowed me to lower the switch assembly and inspect the circuit board (CB) inside. ... Read more I tried to operate the switch directly on the CB (i.e. bypassing the button hoping it might be something mechanical with the button, but still could not turn the lights off. Believing the CB was bad, I ordered a new one.

Power off to hood. I installed the new CB but I still could not turn the hood lights off.

I then ordered the next higher assembly circuit board (looking at the PartsSelect.com drawing).

Second attempt: Received the new CB. Power off to the hood. Getting this CB down so that I could replace it was a problem, as it was higher up in the hood and was very space limited, and having to work upside down, looking up into the hood. I used a double ended phillips screwdrive with 90 deg bends on both ends for the four screws holding the cover on the housing with the CB inside. The screws were recessed in the cover. Once I got the head exposed, I used pliers to turn the screws out a bit faster. We're talking a quarter turn at a time here. Once the cover was off, I dopped the CB down using the service loop. I removed the old CB and installed the new one, carefully changing out each connection one at a time. This required the loosening of two very small terminal screws in a cconnection block mounted on the CB for the power lines .You need a very small good quality screwdriver that fits the screws good to get them loose, as they were very tight and it would be possible to damage the CB if you twisted the block on the board (be very careful here). There are also four other slip on connector and one multi-pinned connector (care required here also to avoid bending any of the very small pins). No soldering required. I tested the system with the CB dangling from the hood and everything worked. I put the CB back up in the housing, making sure the wires would not be pinched by the cover (which only goes on one way in order to "clamp" the wires in place), carefully put the cover in place, and put the four screws back in, I then tucked the service loop back up out of the way, and put the hood filters back in place.

Power back on and a final test.... All good.

One other thing. The CBs should be handled with care reqarding static discharge. Touching the hood and handling the boards by their edges is probably a good idea.

I hope this helps someone.

Thanks PartSelect. com

P.S. Any chance of returning the first CB which I didn't need?

Read less

Was this instruction helpful to you?

Thank you for voting!

- Customer:

- Michael from Big sky, MT

- Parts Used:

- 49001053

- Difficulty Level:

- Easy

- Total Repair Time:

- 15 - 30 mins

- Tools:

- Screw drivers

The on/off button stopped working, although fan controls worked fine.

I removed the face of the lower located plastic box. I wrote down a description of current wire locations so I could duplicate that with the new control board. The switch out required a head lamp and a strong, small flat screw driver. This screwdriver is not a common size, and needed to be stronger than the eyeglass screwdriver I initi

... Read more

ally tried. Minus the time to borrow that screwdriver from a neighbor, the fix took about 10 mins. I was upset I've waited 6 mos. to attempt this simple fix.

Read less

Was this instruction helpful to you?

Thank you for voting!

- Customer:

- Jorge from Saginaw, MI

- Parts Used:

- 49001053

- Difficulty Level:

- Easy

- Total Repair Time:

- 15 - 30 mins

- Tools:

- Screw drivers

Hood lights and fans would not work.

Could not have been any easier thanks to INSTANT REPAIRMAN on PartSelect. The site indicated the electronic board was the problem in 99% of cases. The Maytag repairman had come by earlier indicating the problem could be fixed for $500 or we could have a new hood installed for $2500. Fortunately, I decided to give it a try myself. We order

... Read more

ed the part as per the recommendation on this site, turned off the electricity, switched the electronic board with the new one taking care that all wires matched (actually drew a little diagram), and flipped the switch. It worked! 20 minute installation, personal gratification and $500 richer. Priceless! Thanks PartSelect and thanks Instant Repairman!!!

Read less

Was this instruction helpful to you?

Thank you for voting!