Models

>

DDE7900NCL

DDE7900NCL Hotpoint Dryer

Jump to:

Find Part by Name

Keep searches simple, eg. "belt" or "pump".

Keep searches simple, eg. "belt" or "pump".

In Stock

The lint filter and frame for your dryer traps unwanted lint and debris so your dryer can effectively dry your clothes. If the old lint filter is cracked or clogged, or the dryer takes too long to dry...

No Longer Available

$18.69

This part is the rear dryer drum bearing only. This part helps keep your dryer running smoothly as possible with as little noise as possible.

In Stock

This front drum slide kit comes with two slides with the apppropriate mounting hardware.

No Longer Available

$31.03

This white idler pulley is used for many clothes dryers. A dryer's idler pulley wheel serves to help the belt to rotate the drum.

In Stock

This restring coil kit is used to replace the existing coil in a dryer's heating element.

No Longer Available

$32.09

With this high limit/safety thermostat, a dryer's heating element will cut out if the internal temperature reaches 260 degrees Fahrenheit. This element is meant as a safety device, will kick back in w...

In Stock

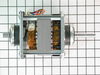

$348.87

Replaces "T" and "V" style motors. Includes two motor pulleys. If you have an older model dryer, the pulley may be pressed on or held on with a set screw. If pulley is pressed on, a new motor pulley must be ordered.

In Stock

This part has three terminals. Note: Use the two smaller terminals for models that only have two wires to the switch.

No Longer Available

In Stock

Questions and Answers

We're sorry, but our Q&A experts are temporarily unavailable.

Please check back later if you still haven't found the answer you need.

Common Problems and Symptoms for DDE7900NCL

Viewing 2 of 2Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

- Customer:

- Matt from La Belle, MO

- Parts Used:

- WE12X10014

- Difficulty Level:

- A Bit Difficult

- Total Repair Time:

- 15 - 30 mins

- Tools:

- Nutdriver, Screw drivers, Socket set

dryer belt broke

first I took the dryer apart 1st thing i did was unplug the power supply (safety first) then I removed the top of the unit then removed the front cleaned all the lint from the inside of the cabinet I found the proper belt size on part select.com the next day I had my dryer belt delivered (which cost 1/3 the price of the local repair shop

... Read more

price)

then I placed the belt over the dryer drum and made sure it was in the general location it should be I then replaced the front cover and the top. then I removed the rear cover which was held on by six 5/16 sheet metal screws which gave me access to the drive pulley and belt tensioner the belt goes on by going under the tensioner then around the drive pulley

Then i rotated the drum by hand to make sure everything had clearance I then buttend everything up plugged it and started it up it workd fine and I figure Ill get another 8 years out of it

Thank you partselect.com

then I placed the belt over the dryer drum and made sure it was in the general location it should be I then replaced the front cover and the top. then I removed the rear cover which was held on by six 5/16 sheet metal screws which gave me access to the drive pulley and belt tensioner the belt goes on by going under the tensioner then around the drive pulley

Then i rotated the drum by hand to make sure everything had clearance I then buttend everything up plugged it and started it up it workd fine and I figure Ill get another 8 years out of it

Thank you partselect.com

Read less

Was this instruction helpful to you?

Thank you for voting!

- Customer:

- Todd from Clarksburg, OH

- Parts Used:

- WE11X260

- Difficulty Level:

- A Bit Difficult

- Total Repair Time:

- More than 2 hours

- Tools:

- Nutdriver, Pliers, Screw drivers, Socket set, Wrench (Adjustable), Wrench set

dryer would run but no heat

first had to troubleshoot... used multimeter to check all switches, they were good.

then checked thermostats, good again.

then checked motor centrifugal switch.. good.

with multimeter i found continuity between heating coil leads and heater housing. coil had broken and welded itself to housing.

... Read more changed coil in short time with restring kit (which got here amazingly fast) and everything is great.

ps: PartsSelect got me the part super fast and it was what i needed. also at a great price. would order from them again.

added note: if i were to do this again i would order the porcelain insulators that insulate the leads to the coils, they were old and very fragile and i experienced some fragmentation.

thanks to PartsSelect

then checked thermostats, good again.

then checked motor centrifugal switch.. good.

with multimeter i found continuity between heating coil leads and heater housing. coil had broken and welded itself to housing.

... Read more changed coil in short time with restring kit (which got here amazingly fast) and everything is great.

ps: PartsSelect got me the part super fast and it was what i needed. also at a great price. would order from them again.

added note: if i were to do this again i would order the porcelain insulators that insulate the leads to the coils, they were old and very fragile and i experienced some fragmentation.

thanks to PartsSelect

Read less

Was this instruction helpful to you?

Thank you for voting!

- Customer:

- Robert from Virginia Beach, VA

- Parts Used:

- WE4X197

- Difficulty Level:

- Really Easy

- Total Repair Time:

- Less than 15 mins

- Tools:

- Screw drivers

replqce bad switch

pried old switch assembly from front of machine with screw driver. removed 2 electrical connections. shorted terminals to verify problem. inserted wiring terminals to new switch. verified operation and then pushed switch assembly into machine opening.

Was this instruction helpful to you?

Thank you for voting!