Models

>

DLB2650WAL

DLB2650WAL Hotpoint Dryer

Jump to:

Find Part by Name

Keep searches simple, eg. "belt" or "pump".

Keep searches simple, eg. "belt" or "pump".

$88.17

This rear drum bearing kit is a genuine OEM replacement for your dryer. The kit includes a shaft, ground strap, bracket, bearing and seven screws for installation. The bearing supports that back of th...

In Stock

$18.69

This part is the rear dryer drum bearing only. This part helps keep your dryer running smoothly as possible with as little noise as possible.

In Stock

This restring coil kit is used to replace the existing coil in a dryer's heating element.

No Longer Available

$32.09

With this high limit/safety thermostat, a dryer's heating element will cut out if the internal temperature reaches 260 degrees Fahrenheit. This element is meant as a safety device, will kick back in w...

In Stock

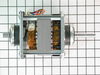

$348.87

Replaces "T" and "V" style motors. Includes two motor pulleys. If you have an older model dryer, the pulley may be pressed on or held on with a set screw. If pulley is pressed on, a new motor pulley must be ordered.

In Stock

This dryer drum belt goes around the dryer drum and the pulleys to rotate the drum once motor is activate.

No Longer Available

This heating element coil restring kit is intended for use with many of GE's brands of electric clothes dryers. It carries 250 volts, and includes two coils.

No Longer Available

Questions and Answers

We're sorry, but our Q&A experts are temporarily unavailable.

Please check back later if you still haven't found the answer you need.

Common Problems and Symptoms for DLB2650WAL

Viewing 3 of 3Noisy

Fixed by these parts

How to fix it

Too hot

Fixed by these parts

How to fix it

Marks left on clothes

Fixed by these parts

How to fix it

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

- Customer:

- Todd from Clarksburg, OH

- Parts Used:

- WE11X260

- Difficulty Level:

- A Bit Difficult

- Total Repair Time:

- More than 2 hours

- Tools:

- Nutdriver, Pliers, Screw drivers, Socket set, Wrench (Adjustable), Wrench set

dryer would run but no heat

first had to troubleshoot... used multimeter to check all switches, they were good.

then checked thermostats, good again.

then checked motor centrifugal switch.. good.

with multimeter i found continuity between heating coil leads and heater housing. coil had broken and welded itself to housing.

... Read more changed coil in short time with restring kit (which got here amazingly fast) and everything is great.

ps: PartsSelect got me the part super fast and it was what i needed. also at a great price. would order from them again.

added note: if i were to do this again i would order the porcelain insulators that insulate the leads to the coils, they were old and very fragile and i experienced some fragmentation.

thanks to PartsSelect

then checked thermostats, good again.

then checked motor centrifugal switch.. good.

with multimeter i found continuity between heating coil leads and heater housing. coil had broken and welded itself to housing.

... Read more changed coil in short time with restring kit (which got here amazingly fast) and everything is great.

ps: PartsSelect got me the part super fast and it was what i needed. also at a great price. would order from them again.

added note: if i were to do this again i would order the porcelain insulators that insulate the leads to the coils, they were old and very fragile and i experienced some fragmentation.

thanks to PartsSelect

Read less

Was this instruction helpful to you?

Thank you for voting!

- Customer:

- Jason from Cary, NC

- Parts Used:

- WE25M40

- Difficulty Level:

- A Bit Difficult

- Total Repair Time:

- More than 2 hours

- Tools:

- Screw drivers, Socket set

Squeaking Dryer - Rear Drum bearing gone bad

First, I loosened the the top control panel and then loosened the top flat roof panel which allowed me access to the inside of the dryer. Then, I removed the front panel which allowed access to the drum. I was amazed at the amount of lint that was inside the dryer itself. Most of my time was spent in the disassembly and cleaning of the in

... Read more

ternal cavity around the drum. I reached below the drum and removed the belt from the pulley wheels and then unscrewed the drum (from the inside) from the back of the dryer and bearing kit. I removed the diffuser and cleaned it thoroughly. Then I replaced the entire drum bearing kit - the old one was almost completely dissentigrated. I probably should have applied some kind of non-flammable lubricant to the new bearing kit - the instructions did not include this step but after about 3 loads a slight squeak (different). I put everything back together - applying the new drum kit will require 2 sets of hands (my 9-year old daughter did great at this). I re-assembled the dryer and it works great, again except for the slight squeak that's still there. I may disassemble it again and apply some lubricant but I do not know what kind to get; I need to check that out.

Read less

Was this instruction helpful to you?

Thank you for voting!

- Customer:

- Mark from Garrett, IN

- Parts Used:

- WE25M40

- Difficulty Level:

- A Bit Difficult

- Total Repair Time:

- More than 2 hours

- Tools:

- Nutdriver, Screw drivers, Socket set

Dryer squeaked when running

Everything is cleaned as it is removed.

Remove the two screws holding the top down.

Disconnect two wires from door switch.

Remove the two hex screws holding the front on.

Remove the 4 screws holding the access panel on the back and disengage idler pulley to loosen the belt.

Remove the drum.

Label the wi ... Read more res then remove the heating element.

Check orientation of ground strap before disassembling rear bearing.

Remove four screws holding rear bearing to back of heating element.

Install rear bearing and ground strap on to heating element.

Reinstall heating element.

Reconnect wires.

Most Important : Get help putting parts back on drum! I didn't and that's why it took over 2 hours.

I will describe how I did it.

Unscrew bearing from inside of drum.

Wrap screwdriver with tape to a little larger than the screw hole.

Use small screwdriver to line up the drum, shim and deflector.

Don't forget the brass shim. It wasn't on the parts diagram.

Start two screws don't tighten them yet.

Remove Screwdriver and start third screw. Tighten all three down.

Put belt on drum.

Install drum and belt.

Reverse disassembly.

When putting the front on make sure drum rests in the felt.

I rated this a bit difficult because I did it myself. With help this is a fairly easy repair.

Remove the two screws holding the top down.

Disconnect two wires from door switch.

Remove the two hex screws holding the front on.

Remove the 4 screws holding the access panel on the back and disengage idler pulley to loosen the belt.

Remove the drum.

Label the wi ... Read more res then remove the heating element.

Check orientation of ground strap before disassembling rear bearing.

Remove four screws holding rear bearing to back of heating element.

Install rear bearing and ground strap on to heating element.

Reinstall heating element.

Reconnect wires.

Most Important : Get help putting parts back on drum! I didn't and that's why it took over 2 hours.

I will describe how I did it.

Unscrew bearing from inside of drum.

Wrap screwdriver with tape to a little larger than the screw hole.

Use small screwdriver to line up the drum, shim and deflector.

Don't forget the brass shim. It wasn't on the parts diagram.

Start two screws don't tighten them yet.

Remove Screwdriver and start third screw. Tighten all three down.

Put belt on drum.

Install drum and belt.

Reverse disassembly.

When putting the front on make sure drum rests in the felt.

I rated this a bit difficult because I did it myself. With help this is a fairly easy repair.

Read less

Was this instruction helpful to you?

Thank you for voting!