Models

>

MZF34X18FW00

MZF34X18FW00 Maytag Freezer

Jump to:

Find Part by Name

Keep searches simple, eg. "belt" or "pump".

Diagrams for MZF34X18FW00

Viewing 6 of 6Keep searches simple, eg. "belt" or "pump".

$20.79

This is a screw and it is made for multiple appliances in your home. This model is called a sheet metal screw because it has sharp points, and the threads are closer together. This screw is designed t...

In Stock

$8.00

This 18 ml bottle of white appliance touch-up paint is used to cover scratches or marks on your appliance. The white touch-up paint can be used on refrigerators, microwaves, ranges, clothes dryers, an...

In Stock

In Stock

$48.72

This is a genuine replacement light bulb for a refrigerator. The inside of your refrigerator should illuminate when you open the door. If your fridge does not illuminate, you may need to replace this ...

On Order

$37.20

If your refrigerator or freezer is too warm, or making noises, you may need to replace the fan blade. The fan blade attaches to the evaporator motor, which is in the freezer section, to help circulate...

In Stock

This temperature sensor is for refrigerators.

The temperature sensor senses the temperature inside the refrigerator and sends information to the electronic control.

Unplug the refrigerator and s...

In Stock

In Stock

In Stock

In Stock

In Stock

In Stock

In Stock

Questions and Answers

We're sorry, but our Q&A experts are temporarily unavailable.

Please check back later if you still haven't found the answer you need.

Common Problems and Symptoms for MZF34X18FW00

Viewing 6 of 6Noisy

Fixed by these parts

How to fix it

Fridge too warm

Fixed by these parts

How to fix it

Freezer not defrosting

Fixed by these parts

How to fix it

Frost buildup

Fixed by these parts

How to fix it

Will Not Start

Fixed by these parts

How to fix it

Fridge and Freezer are too warm

Fixed by these parts

How to fix it

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

- Customer:

- Michelle from Richardson, TX

- Parts Used:

- 72017

- Difficulty Level:

- Really Easy

- Total Repair Time:

- Less than 15 mins

Scratches in Surface

This product comes in a bottle with a brush like Liquid Paper. It goes on incredibly easy. A second coat might be needed. I wanted to prevent rust from setting in so I covered the scratches and dings. The paint is a little brighter since my washer is 10 years old but it still looks great.

Was this instruction helpful to you?

Thank you for voting!

- Customer:

- Ken from HOLLAND, MI

- Parts Used:

- W10873801, WPW10350564

- Difficulty Level:

- Very Easy

- Total Repair Time:

- 15 - 30 mins

- Tools:

- Nutdriver, Screw drivers

Compressor would not run. My daughter was told that compressor was bad and needed to be replaced. Cost would be $550 labor plus parts. I could hear a clicking sound I believe was made by the starter relay. I ordered the parts from part select and had them in three days.

I took the screws out of back panel and slid water line and panel off to the right side while I removed the capacitor and starter relay. Relay was probably the only problem, but I replaced capacitor too while I was doing the repair. Finished removal and replacement in about 20 minutes. While I had panel off I cleaned coils that I coul

... Read more

d see from behind and then did the same on front side. Cost was $136 for both parts. I could have done it for $71 if I did not replace the capacitor too. Saved my daughter from being taken advantage of.

Read less

Was this instruction helpful to you?

Thank you for voting!

- Customer:

- Daniel from BOCA RATON, FL

- Parts Used:

- WPW10515763, WPW10141622

- Difficulty Level:

- A Bit Difficult

- Total Repair Time:

- 30 - 60 mins

- Tools:

- Nutdriver, Screw drivers, Socket set

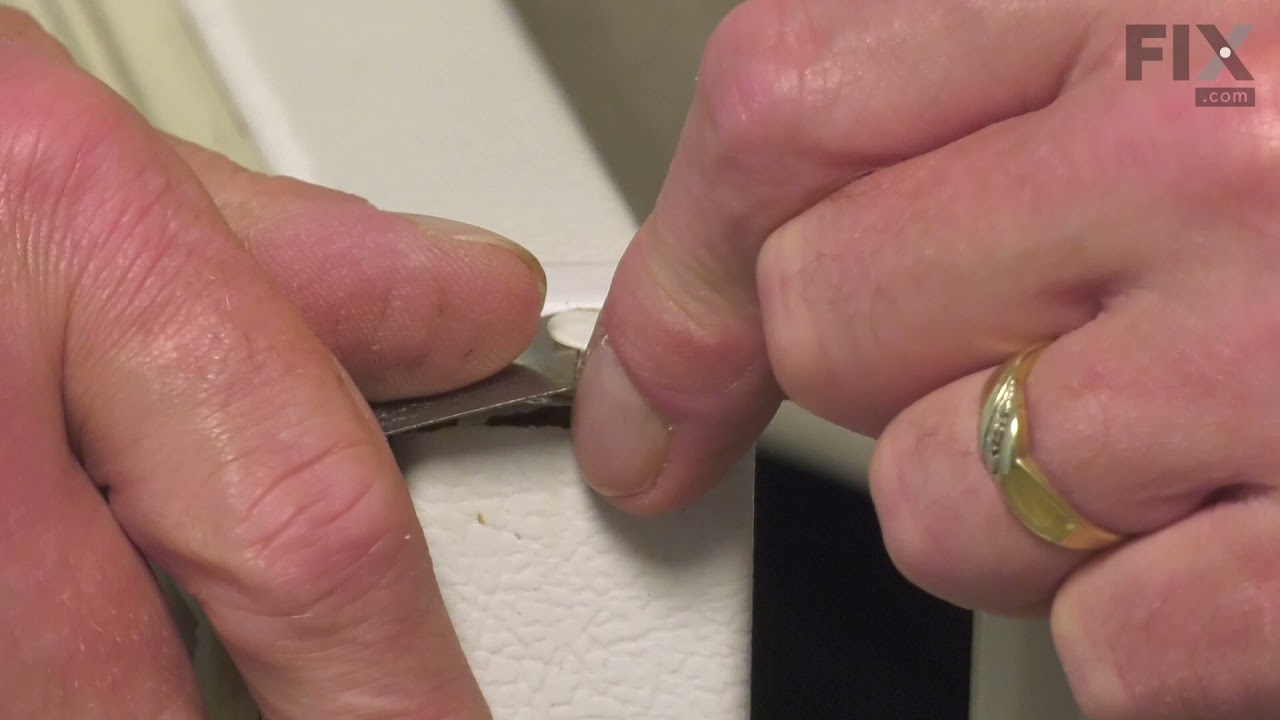

Original bracket foot brake screw hole was stripped and foot brake would not extend

The repair seemed simple, I just needed to remove the old bracket -- 4 screws -- and slip the new one on.

The tricky bit is that the roller bracket holds the weight of the fridge. So in order to make sure that the fridge did not fall over, and to keep the installation point off the ground so that I could align the screw holes, ... Read more I needed to shim up the side of the fridge that I was working on.

To tap in the shims, I used a hammer and a spare chunk of wood. I ultimately used 3 shims, and kept tapping until the roller wheel could roll freely. Then I knew that the fridge was high enough. After that, it was pretty easy to remove the 4 screws, align the new bracket, and replace the screws. After that, in order to get the shims out I could just extend the foot brake as it was designed, and that lifted the fridge enough for me to easily slide out the shims. After that I just had to level out the fridge by adjusting the two feet.

The tricky bit is that the roller bracket holds the weight of the fridge. So in order to make sure that the fridge did not fall over, and to keep the installation point off the ground so that I could align the screw holes, ... Read more I needed to shim up the side of the fridge that I was working on.

To tap in the shims, I used a hammer and a spare chunk of wood. I ultimately used 3 shims, and kept tapping until the roller wheel could roll freely. Then I knew that the fridge was high enough. After that, it was pretty easy to remove the 4 screws, align the new bracket, and replace the screws. After that, in order to get the shims out I could just extend the foot brake as it was designed, and that lifted the fridge enough for me to easily slide out the shims. After that I just had to level out the fridge by adjusting the two feet.

Read less

Was this instruction helpful to you?

Thank you for voting!