Models

>

4GWED5500YW3

4GWED5500YW3 Whirlpool Dryer

Jump to:

Find Part by Name

Keep searches simple, eg. "belt" or "pump".

Diagrams for 4GWED5500YW3

Viewing 5 of 5Keep searches simple, eg. "belt" or "pump".

$19.63

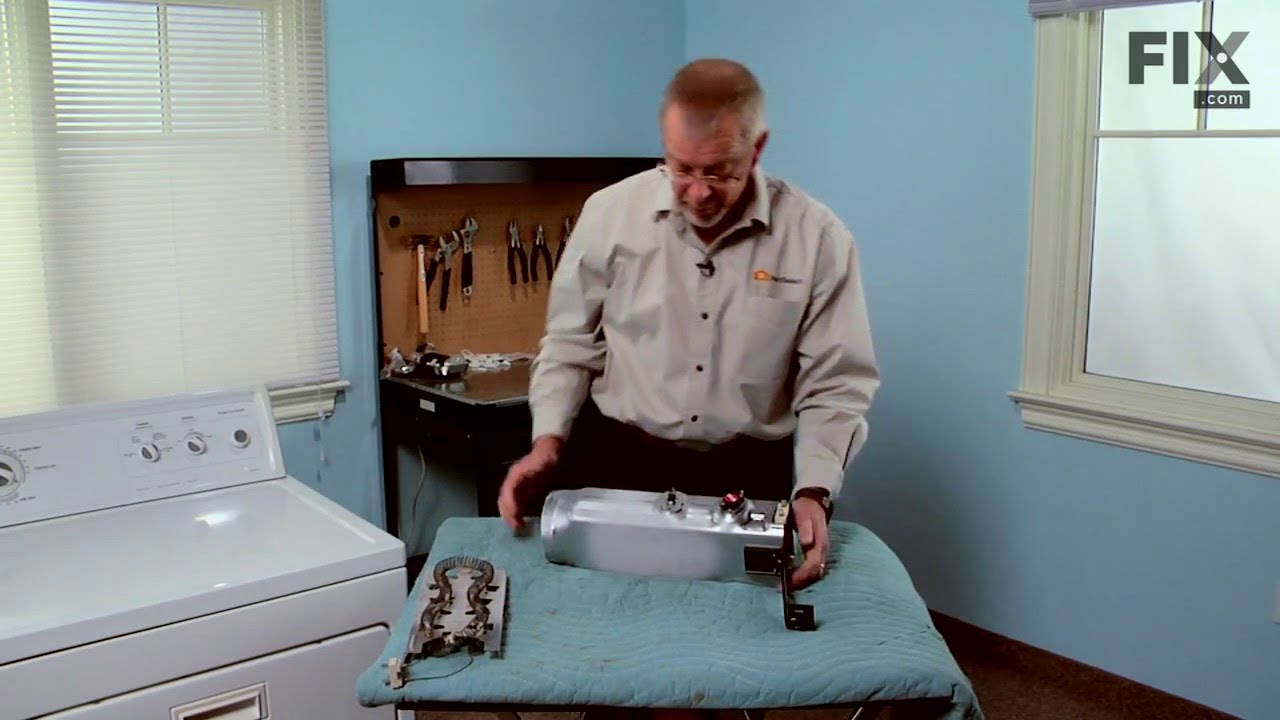

The dryer thermal fuse, also sometimes referred to as the thermal cut off or temperature fuse, is a 2 by 1/2-inch, white, plastic safety mechanism that halts the flow of electricity to the motor circu...

In Stock

$94.64

When connected to electricity the dryer heating element glows red hot and generates heat. When air is blown over it, it heats the air which is used to dry the clothes. The heating element fits inside ...

In Stock

$26.95

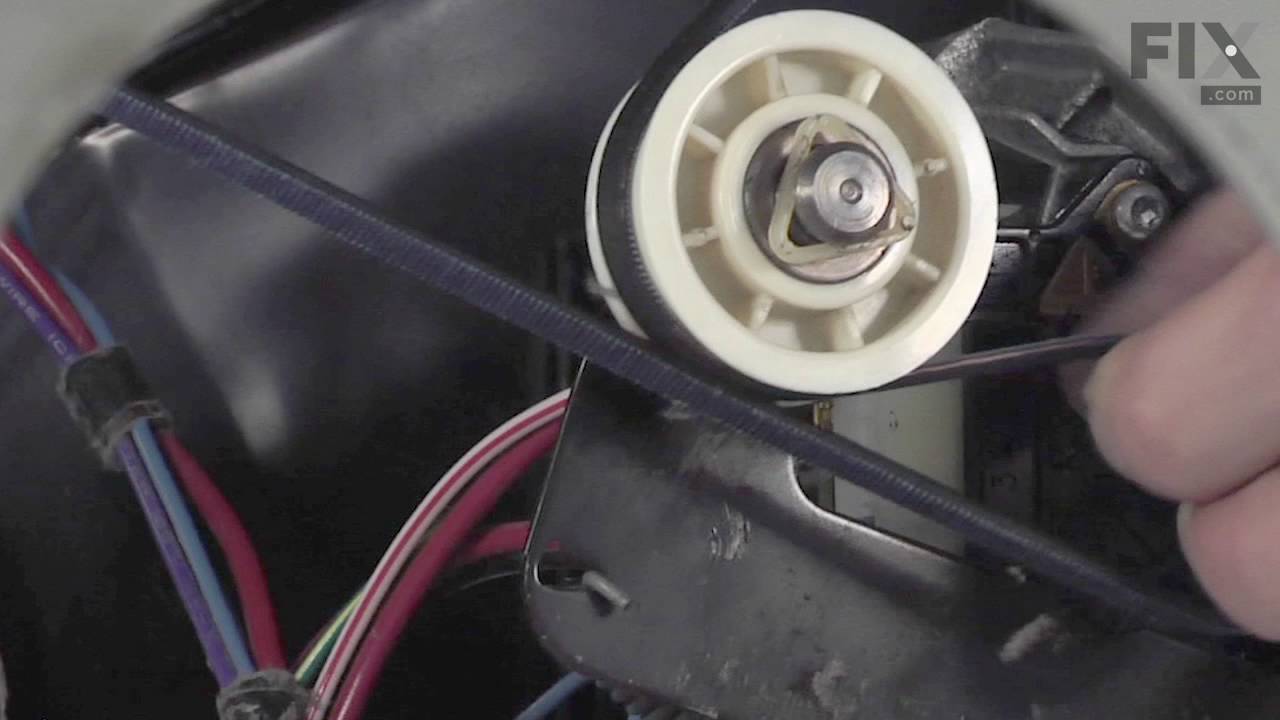

Often referred to as a dryer belt tension pulley wheel, this idler pulley is an OEM approved replacement part for a variety of dryer models. The idler pulley puts tension on the drive belt, and if the...

In Stock

$61.46

If the lint filter in your dryer has become damaged and unusable, it is important to replace it as soon as possible. The filter traps lint and other debris from your laundry, keeping it out of your ai...

In Stock

$22.69

This drum support roller is sold individually. Most dryers require two. The tri-rings are included. This is a drum support roller for a dryer. It is a genuine replacement part. The part includes the d...

In Stock

$53.59

This dryer repair kit consists of five commonly replaced dryer parts: one multi-rib belt (part #661570V and measures 93 1/2 inches long), four drum support rollers, one idler assembly, nine tri-rings,...

In Stock

This is a single dryer drum belt that measures 93.5 inches. The belt rotates the dryer drum and is a common wear part that can become brittle over time. It can also stretch and change shape, so keep t...

No Longer Available

$13.42

This small but mighty OEM piece is called a tri-ring and is used to support the drum roller shaft and the idler pulley shaft in your dryer. It helps to provide a tight seal between components by evenl...

In Stock

$47.74

The internal-bias thermostat, also know as a thermistor, is used to prevent the dryer from overheating. It does this by monitoring and controlling the temperature of the inside of the dryer drum. If ...

In Stock

$11.40

It is important for your dryer to be properly leveled, as an unleveled one can cause excessive vibration and noise when operating, may not drain properly, and can cause excessive wear on various parts...

In Stock

This thermal cut-off kit includes a genuine OEM replacement high limit thermostat and a fuse. The thermostat is a safety device used to prevent the dryer from overheating, and the fuse serves as a bac...

In Stock

$26.79

If your dryer is not tumbling, will not start, or is excessively noisy while operating, there may be an issue with your idler pulley. The idler pulley works by maintaining a constant tension on the dr...

In Stock

Questions and Answers

We're sorry, but our Q&A experts are temporarily unavailable.

Please check back later if you still haven't found the answer you need.

Common Problems and Symptoms for 4GWED5500YW3

Viewing 11 of 11Noisy

Fixed by these parts

How to fix it

Too hot

Fixed by these parts

How to fix it

Not Heating

Fixed by these parts

How to fix it

Door won’t close

Fixed by these parts

How to fix it

Marks left on clothes

Fixed by these parts

How to fix it

Won’t Start

Fixed by these parts

How to fix it

Drum Not Spinning

Fixed by these parts

How to fix it

Touchpad does not respond

Fixed by these parts

How to fix it

Will Not Start

Fixed by these parts

How to fix it

Heat stays on after drum has stopped

Fixed by these parts

How to fix it

Door Pops Open

Fixed by these parts

How to fix it

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

- Customer:

- ANTHONY from CHESHIRE, CT

- Parts Used:

- WP3392519

- Difficulty Level:

- Easy

- Total Repair Time:

- 15 - 30 mins

- Tools:

- Nutdriver, Pliers, Screw drivers

Dryer was working, but no heat.

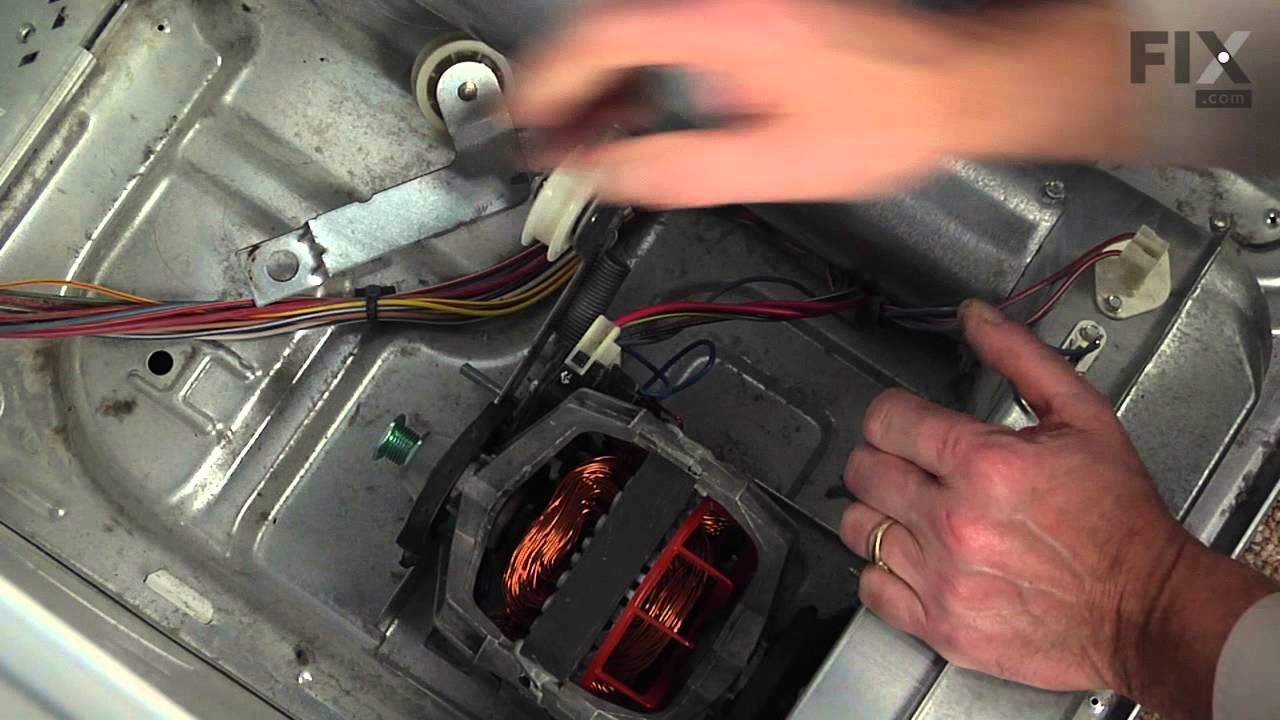

First I unplugged the dryer, then removed the back panel, this exposed most all of the wiring and I could see the heater coils.

Not knowing what the problem was I started looking at the coils and could not see any broken parts.

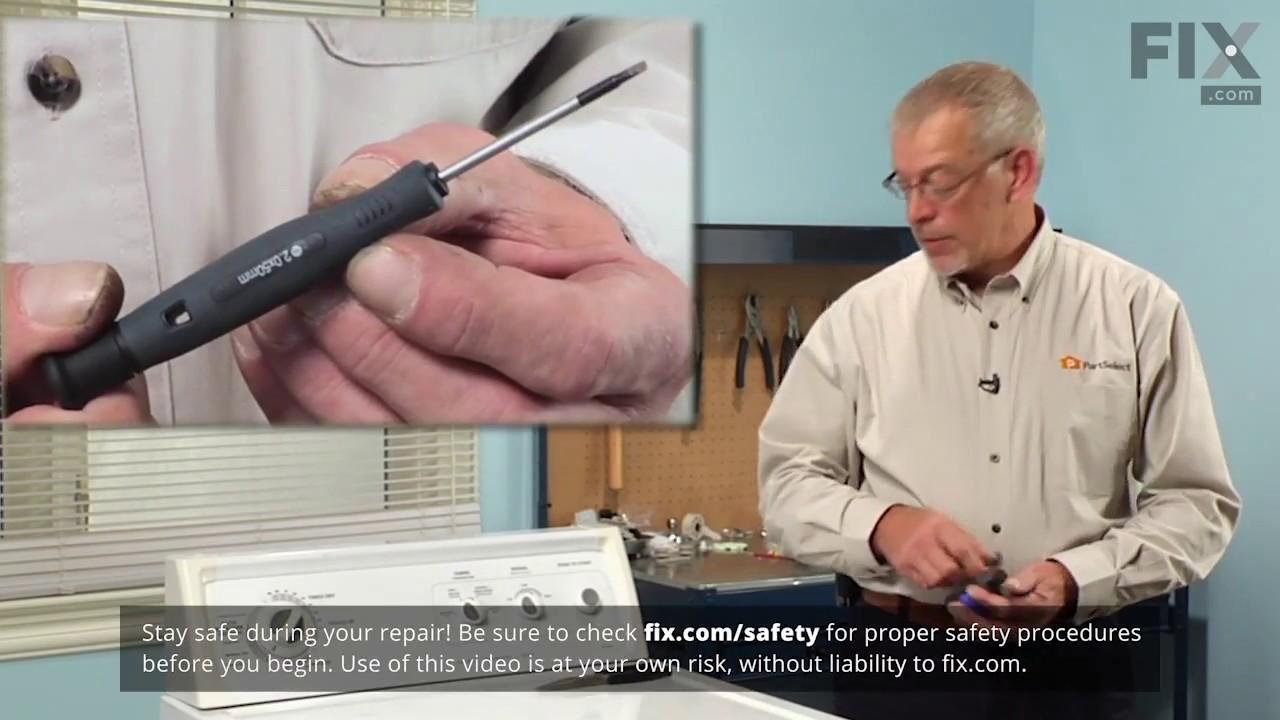

So then checked the thermal fuse for continuity I removed the two wires from it with a small pair of ... Read more needle nose pliers, it was held in place by two screws, once they were removed the fuse came out easily, I checked continuity with a volt meter placing the meter on X1 Ohms and could not get a reading.

I replaced with a new one and put it all back together the way I took it apart.

Then I plugged it in and it worked first time, I now have warm dry clothes.

Not knowing what the problem was I started looking at the coils and could not see any broken parts.

So then checked the thermal fuse for continuity I removed the two wires from it with a small pair of ... Read more needle nose pliers, it was held in place by two screws, once they were removed the fuse came out easily, I checked continuity with a volt meter placing the meter on X1 Ohms and could not get a reading.

I replaced with a new one and put it all back together the way I took it apart.

Then I plugged it in and it worked first time, I now have warm dry clothes.

Read less

Was this instruction helpful to you?

Thank you for voting!

- Customer:

- Dana from Grassvally, CA

- Parts Used:

- WP3392519

- Difficulty Level:

- A Bit Difficult

- Total Repair Time:

- More than 2 hours

- Tools:

- Screw drivers

No heat but would run otherwise

Cleaning the lint out of the whole machine took quite a bit of time--it was everywhere. Underneath the lint trap was a collection that ultimately ruined the thermal fuse where it restricted the air flow considerably.

Ascertaining the problem was the most time consuming part.

The actual repair was quite simple and did ... Read more n't take but 15-20 minutes.

Ascertaining the problem was the most time consuming part.

The actual repair was quite simple and did ... Read more n't take but 15-20 minutes.

Read less

Was this instruction helpful to you?

Thank you for voting!

- Customer:

- Alan from Brooksville, FL

- Parts Used:

- WP3387747

- Difficulty Level:

- Easy

- Total Repair Time:

- 30 - 60 mins

- Tools:

- Socket set

Burned out heater element

Remove the kick plate from the bottom of the dryer by sliding a putty knife along the top edge to release the plastic clamps, one on each side about 4" in from the edges. The kick plate folds out and down. You will see the heat shield on the right, held in by one hex head screw. Remove screw and heat shield. The element is positioned in a

... Read more

n open-front housing and is fastened to the left side of the housing by two hex head screws, located on the "rail" of the element and right near the two wires. Remove the hex-head screws that hold the element in place and disconnected the two wires by pulling them out by hand or with needle nose pliers. The only difficulty here is the cramped working area...I recommend a stubby socket driver for these two screws. Most of this I had to do by feel because I could not see the screw heads. Once the screws are out and the wires have been disconnected, slide the old element straight out toward you. You may need to disconnect a small plastic hose located to the left front of the element, but this hose just pulls right off. Vacume the dust & lint build-up out of the whole area, wipe out the element housing and clean up the whole underside of the dryer prior to installing the new element. Installation is reverse of removal. It also might be a good opportunity to clean out your exhaust duct and the vent to the outside. (Never use the aluminum foil-accordian-type duct.) If the exterior dryer vent has any kind of screen over it, remove it and get rid of it. Screens collect lint, lint builds up and burns out elements.

Read less

Was this instruction helpful to you?

Thank you for voting!