Models

>

MED8630HC1

MED8630HC1 Maytag Dryer

Jump to:

Find Part by Name

Keep searches simple, eg. "belt" or "pump".

Diagrams for MED8630HC1

Viewing 5 of 5Keep searches simple, eg. "belt" or "pump".

$94.64

When connected to electricity the dryer heating element glows red hot and generates heat. When air is blown over it, it heats the air which is used to dry the clothes. The heating element fits inside ...

In Stock

Order within the next 9 hrs and your part ships today!

$26.95

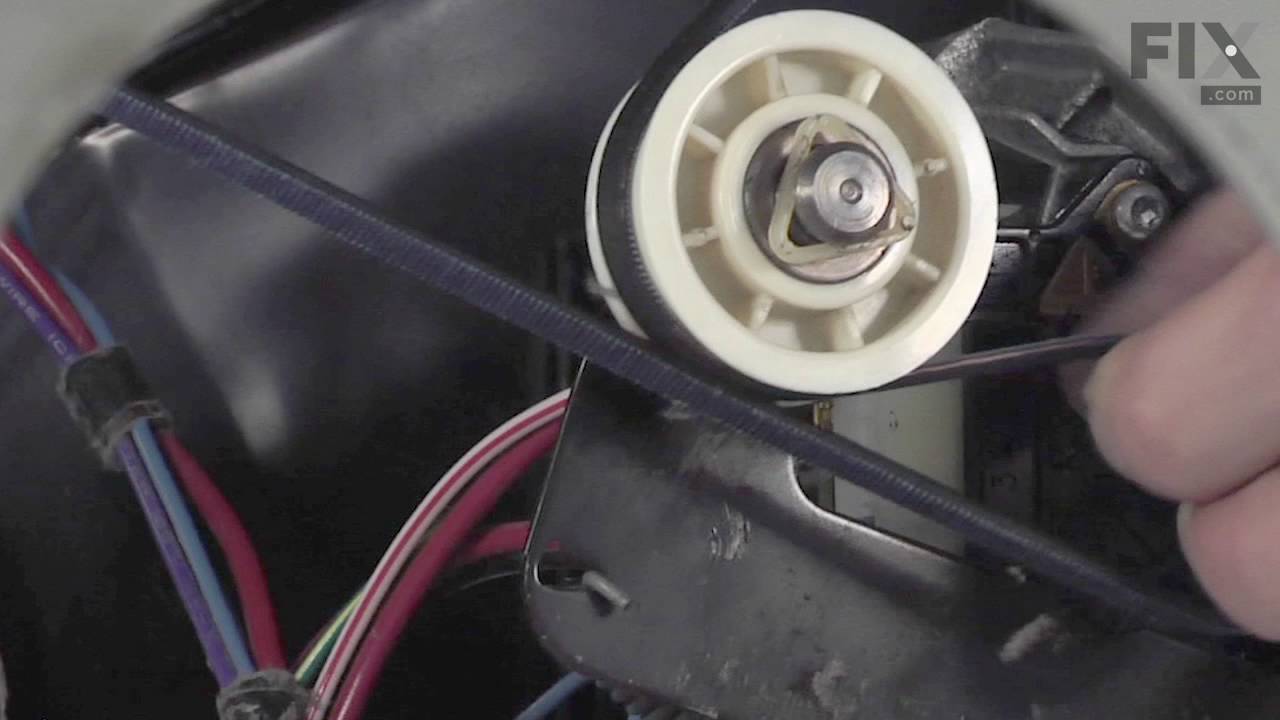

Often referred to as a dryer belt tension pulley wheel, this idler pulley is an OEM approved replacement part for a variety of dryer models. The idler pulley puts tension on the drive belt, and if the...

In Stock

Order within the next 9 hrs and your part ships today!

$22.69

This drum support roller is sold individually. Most dryers require two. The tri-rings are included. This is a drum support roller for a dryer. It is a genuine replacement part. The part includes the d...

In Stock

Order within the next 9 hrs and your part ships today!

$53.59

This dryer repair kit consists of five commonly replaced dryer parts: one multi-rib belt (part #661570V and measures 93 1/2 inches long), four drum support rollers, one idler assembly, nine tri-rings,...

In Stock

Order within the next 9 hrs and your part ships today!

This is a single dryer drum belt that measures 93.5 inches. The belt rotates the dryer drum and is a common wear part that can become brittle over time. It can also stretch and change shape, so keep t...

No Longer Available

$13.42

This small but mighty OEM piece is called a tri-ring and is used to support the drum roller shaft and the idler pulley shaft in your dryer. It helps to provide a tight seal between components by evenl...

In Stock

Order within the next 9 hrs and your part ships today!

$47.74

The internal-bias thermostat, also know as a thermistor, is used to prevent the dryer from overheating. It does this by monitoring and controlling the temperature of the inside of the dryer drum. If ...

In Stock

Order within the next 9 hrs and your part ships today!

$11.40

It is important for your dryer to be properly leveled, as an unleveled one can cause excessive vibration and noise when operating, may not drain properly, and can cause excessive wear on various parts...

In Stock

Order within the next 9 hrs and your part ships today!

$26.79

If your dryer is not tumbling, will not start, or is excessively noisy while operating, there may be an issue with your idler pulley. The idler pulley works by maintaining a constant tension on the dr...

In Stock

Order within the next 9 hrs and your part ships today!

$10.72

This is an authentic OEM replacement moisture sensor for your dryer. The sensor detects the moisture levels in your clothing while the appliance is operating, and once the appropriate level has been r...

In Stock

Order within the next 9 hrs and your part ships today!

This heating element connection wire kit is a genuine OEM replacement for your electric dryer. The kit is used to connect the thermostat to the heater element. The kit comes with a yellow wire nut and...

In Stock

Order within the next 9 hrs and your part ships today!

This part seals the drum to prevents air from escaping. This includes silicone rubber adhesive.

In Stock

Order within the next 9 hrs and your part ships today!

Questions and Answers

We're sorry, but our Q&A experts are temporarily unavailable.

Please check back later if you still haven't found the answer you need.

- < Prev

- 1

- Next >

Sort by:

Search filter:

Clear Filter

Your search term must have 3 or more characters.

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Sorry, we couldn't find any existing answers that matched.

Try using some different or simpler keywords, or submit your new question by using the "Ask a Question" button above!

Try using some different or simpler keywords, or submit your new question by using the "Ask a Question" button above!

Lee

February 18, 2023

How do i remove the front panel for this Maytag dryer

For model number MED8630HC1

Hi Lee, thank you for reaching out. According to our research, to remove the front panel, first, access the back of the unit. Stop before beginning any repair, and always be sure to disconnect the power. There are two screws, that will have to be removed on the back to take the top off. Then, slide it back and wiggle it. Pull off the top and set it aside. Now the top panel is removed, you can gain access and try to remove the console. To remove your console, use two quarter-inch screws that have to be taken off. Remove the strain reliever to give you a little more room, then remove the screws, but be careful because they are mounted in very durable plastic. Now the front panel on this one is attached at the bottom, inside, and on top. To begin, slide the bit case underneath it, push the side up, and then drop it down. There are four screws underneath that are only a quarter inch long; set your screws aside, then lift it back up. Remove whatever object you propped it up with. Next, open the door. Remove the two Phillips screws right next to the duct. Close the door and switch back over to your quarter inch. Remove these three-quarter-inch screws across the top; now the front panel is kind of hooked on. So, it shouldn't drop right off, but if you feel more comfortable, when you're removing these, make sure you hold them in place. Pull forward on the front panel and lift; there is one strain reliever at the front; smash it with a pair of needle-nose pliers. Push it through, this will create a little more room to reach in. You will have to detach the wiring harness from the top. It will feed through the bottom. Lift your front panel and set the panel aside. Now, the front panel has been removed. We hope this information helps!

Was this helpful?

Thank you for voting!

Common Problems and Symptoms for MED8630HC1

Viewing 10 of 10Noisy

Fixed by these parts

How to fix it

Too hot

Fixed by these parts

How to fix it

Door won’t close

Fixed by these parts

How to fix it

Not Heating

Fixed by these parts

How to fix it

Marks left on clothes

Fixed by these parts

How to fix it

Drum Not Spinning

Fixed by these parts

How to fix it

Lid or door won’t close

Fixed by these parts

How to fix it

Won’t Start

Fixed by these parts

How to fix it

Leaking

Fixed by these parts

How to fix it

Touchpad does not respond

Fixed by these parts

How to fix it

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

- Customer:

- Alan from Brooksville, FL

- Parts Used:

- WP3387747

- Difficulty Level:

- Easy

- Total Repair Time:

- 30 - 60 mins

- Tools:

- Socket set

Burned out heater element

Remove the kick plate from the bottom of the dryer by sliding a putty knife along the top edge to release the plastic clamps, one on each side about 4" in from the edges. The kick plate folds out and down. You will see the heat shield on the right, held in by one hex head screw. Remove screw and heat shield. The element is positioned in a

... Read more

n open-front housing and is fastened to the left side of the housing by two hex head screws, located on the "rail" of the element and right near the two wires. Remove the hex-head screws that hold the element in place and disconnected the two wires by pulling them out by hand or with needle nose pliers. The only difficulty here is the cramped working area...I recommend a stubby socket driver for these two screws. Most of this I had to do by feel because I could not see the screw heads. Once the screws are out and the wires have been disconnected, slide the old element straight out toward you. You may need to disconnect a small plastic hose located to the left front of the element, but this hose just pulls right off. Vacume the dust & lint build-up out of the whole area, wipe out the element housing and clean up the whole underside of the dryer prior to installing the new element. Installation is reverse of removal. It also might be a good opportunity to clean out your exhaust duct and the vent to the outside. (Never use the aluminum foil-accordian-type duct.) If the exterior dryer vent has any kind of screen over it, remove it and get rid of it. Screens collect lint, lint builds up and burns out elements.

Read less

Was this instruction helpful to you?

Thank you for voting!

- Customer:

- jason from HOLDEN, MA

- Parts Used:

- 4392067

- Difficulty Level:

- Really Easy

- Total Repair Time:

- 30 - 60 mins

- Tools:

- Socket set

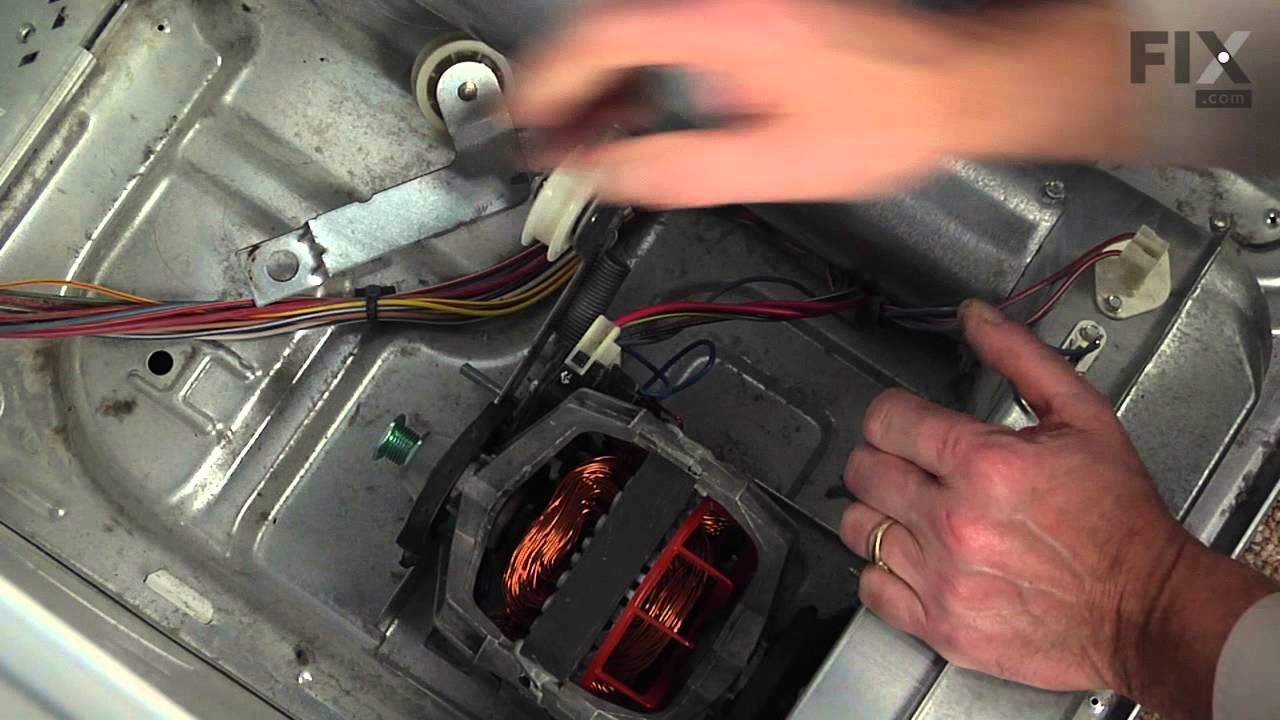

very loud squeeling sound

The issue was the idler pulley. First I began opening up the front panel based on a youtube video but soon realized the model was slightly different and required a lot more items to remove. I saw the pulley in the back with nothing in the way so I put the front panel crap back on and removed the rear panel. There it was, very simple to re

... Read more

move and replace. I'm not looking forward to drum rollers though. Hopefully they're aren't as difficult as they appear.

Read less

Was this instruction helpful to you?

Thank you for voting!

- Customer:

- Jerry from Everett, WA

- Parts Used:

- 280114

- Difficulty Level:

- Easy

- Total Repair Time:

- 30 - 60 mins

- Tools:

- Screw drivers, Socket set

Rear tub seal failure

I removed the top cover and then the back cover, released the belt tensioner and removed the drive belt. Then slid the tub out of the unit and onto the back dack. Sanded the remnents of the old seal off. Wiped the tub lip with laquer thinner and applied the "fast" drying glue supplied with the kit. Installed the seal and re-assembled the

... Read more

unit...works fine

Read less

Was this instruction helpful to you?

Thank you for voting!