Models

>

PSXH43GV1WW

PSXH43GV1WW General Electric Dryer

Jump to:

Find Part by Name

Keep searches simple, eg. "belt" or "pump".

Diagrams for PSXH43GV1WW

Viewing 5 of 5Keep searches simple, eg. "belt" or "pump".

$62.48

This ball-and-socket style bearing kit is used in your dryer to support the rear of the drum as it tumbles through the dry cycle. The bearing attaches on the inside of the rear panel of the dryer cabi...

In Stock

Order within the next 5 hrs and your part ships today!

In Stock

Order within the next 5 hrs and your part ships today!

In Stock

Order within the next 5 hrs and your part ships today!

The upper felt seal for your dryer is attached to the top edge of the drum support area, and is held there by a high temperature adhesive. It creates a seal where the dryer door opens and closes, so t...

In Stock

Order within the next 5 hrs and your part ships today!

$116.35

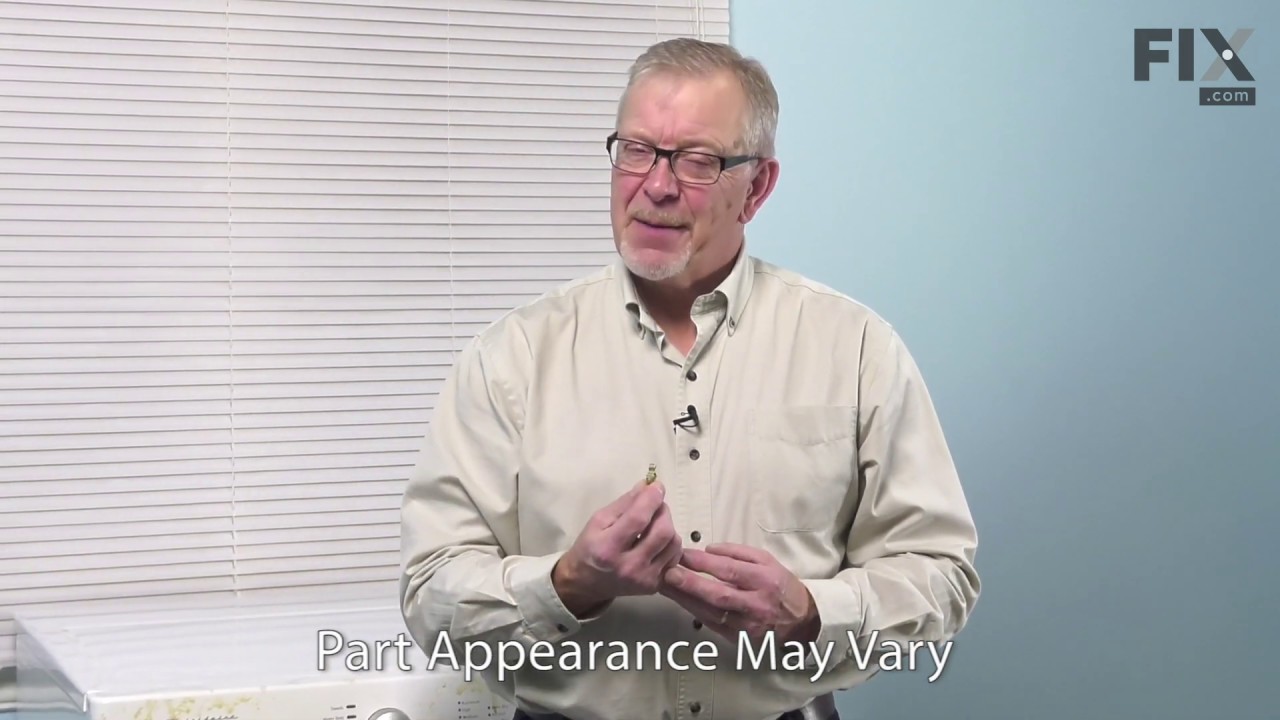

***Please Note: This part is a substituted part by the manufacturer. It may appear different, but should still work with your appliance.

In Stock

Order within the next 5 hrs and your part ships today!

In Stock

Order within the next 5 hrs and your part ships today!

In Stock

Order within the next 5 hrs and your part ships today!

In Stock

Order within the next 5 hrs and your part ships today!

On Order

Questions and Answers

We're sorry, but our Q&A experts are temporarily unavailable.

Please check back later if you still haven't found the answer you need.

Common Problems and Symptoms for PSXH43GV1WW

Viewing 3 of 3Noisy

Fixed by these parts

How to fix it

Door won’t close

Fixed by these parts

How to fix it

Marks left on clothes

Fixed by these parts

How to fix it

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

- Customer:

- Frank from Boyertown, PA

- Parts Used:

- 5303281153

- Difficulty Level:

- Easy

- Total Repair Time:

- 15 - 30 mins

- Tools:

- Nutdriver, Screw drivers

Loud Squeaking

1. Unplug dryer from outlet

2. Using Lg. flat screwdriver, pry under the front edge of the top and release two spring tabs

3. Lift up top and tilt back out of your way

4. Unscrew two phillips scews on inside of front panel

5. Lift up and out the front panel. Two spring clips at bottom.

6. Rlease tension on drum be ... Read more lt at the motor. Access panel at rear of dryer.

7.Unscrew 3 screws from inside, center rear of drum.

8. Remove drum through the front of the dryer. You may have to spread the sides apart a little bit for it to fit

9. Lift up on the rear drum bearing to remove it from the bearing retainer. ( U shaped plastic socket)

10. unsrew 2 screws and remove the bearing retainer, ground ball. Ball retainer is on outside of dryer.

11. Vacuum everything--duct, blower, lint trap, ect.

12. Intall new bearing retainer and grounding ball, an assistant is helpful at this time, one to hold ball retainer on rear of dryer, one to screw it in from the inside

13. reassemble remainder of parts in reverse order.

2. Using Lg. flat screwdriver, pry under the front edge of the top and release two spring tabs

3. Lift up top and tilt back out of your way

4. Unscrew two phillips scews on inside of front panel

5. Lift up and out the front panel. Two spring clips at bottom.

6. Rlease tension on drum be ... Read more lt at the motor. Access panel at rear of dryer.

7.Unscrew 3 screws from inside, center rear of drum.

8. Remove drum through the front of the dryer. You may have to spread the sides apart a little bit for it to fit

9. Lift up on the rear drum bearing to remove it from the bearing retainer. ( U shaped plastic socket)

10. unsrew 2 screws and remove the bearing retainer, ground ball. Ball retainer is on outside of dryer.

11. Vacuum everything--duct, blower, lint trap, ect.

12. Intall new bearing retainer and grounding ball, an assistant is helpful at this time, one to hold ball retainer on rear of dryer, one to screw it in from the inside

13. reassemble remainder of parts in reverse order.

Read less

Was this instruction helpful to you?

Thank you for voting!

- Customer:

- Gerald from Cumming, GA

- Parts Used:

- 5303281153, 131775600

- Difficulty Level:

- Easy

- Total Repair Time:

- 1- 2 hours

- Tools:

- Nutdriver, Pliers, Screw drivers, Socket set, Wrench (Adjustable)

Had 2-seperate problems; 1st was a high pitch squeel, 2nd was the cover overheating

The high pitch squeel was the result of a failing drum bearing. It was particularly evident when first turning on the dryer, but became softer as the dryer heated up. In order to replace the drum bearing, I removed the top panel and front door panel.

The top panel was easily taken off by removing 2-screws from the back edge o ... Read more f the panel, and sliding it back to release it from the front panel seam.

The front panel is more involved, but still relatively easy for your average "do-it-yourselfer". I removed the front door panel by first removing the control panel (4-screws; 2 on top and 2 from the back of the panel). I removed 2 cable assemblies from the control panel via connecters (different sizes so didn't need to mark) and 2-wires attached to the large control panel mode selector (I marked these 2-wires). I set aside the control panel. I removed the front door panel by taking off 6-screws (2 on top, 2 on the bottom, and the remaining 2 on the inside of the panel on either side of the drum). After removing these 6-screws, I carefully pulled the front door panel away from the front of the dryer, carefully releasing 4-alignment latches (2 on either side). The front door panel was still electrically attached to the machine so I had to disconnect a couple more wires. I carefully disconnected 2-wires from the door light assembly and 3 more wires from the door switch (I marked the 3-wires on the door switch). I set aside the front door panel.

From the back of the dryer, I removed the small motor access panel on the bottom left corner. This panel also provides access to the drum belt. I released the drum belt from the motor drive wheel by releasing spring tension at the tensioner. The belt can easily be disconnected from the motor drive wheel and tensioner assemblies.

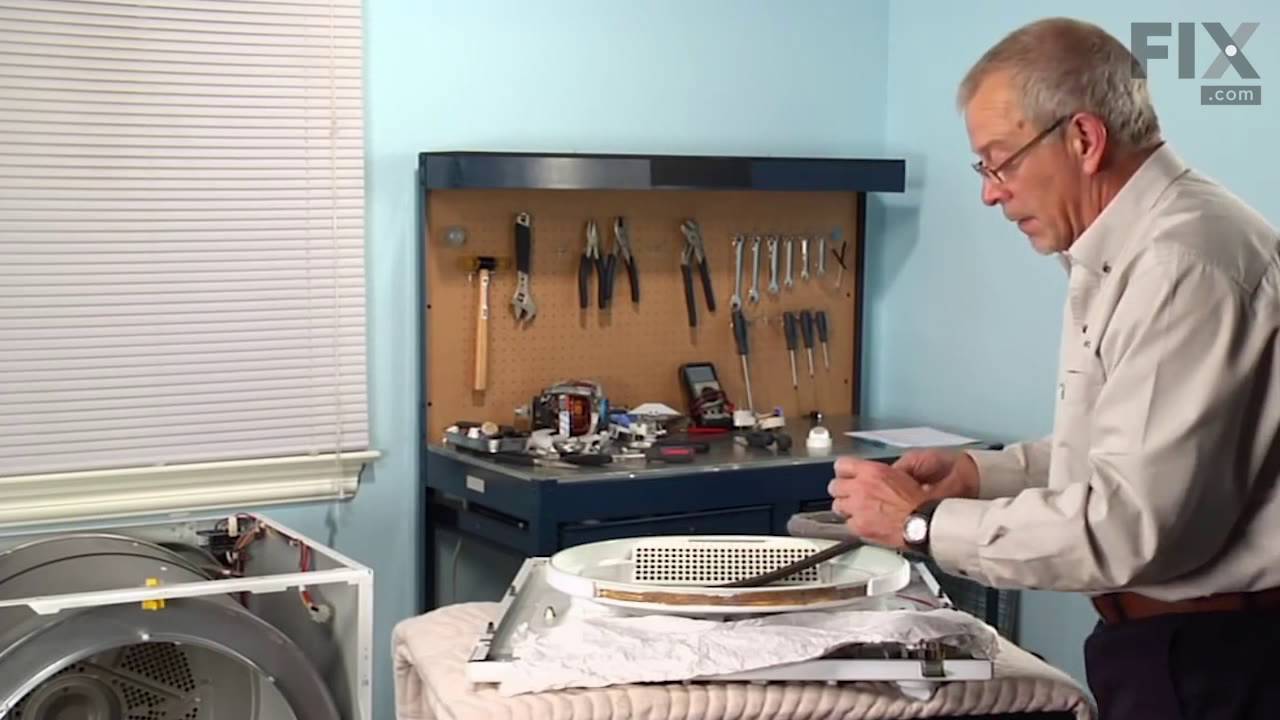

Removal of the drum was now possible. With the front door panel removed, the front of the drum is maintained in place via a small plastic stop on the top crossmember. I removed this stop prior to removing the drum. With one hand, carefully grabbing the belt that is was loosely draped across the back of the drum, and the other hand holding the front lip of the drum, I provided a quick and forceful upward motion to the back of the drum in order to dislodge the drum shaft from the bearing housing assembly. Once this was accomplished, I simple pulled the drum out of the dryer housing via the front of the machine.

The drum bearing repair kit ordered came with the replacement ball bearing, bearing housing, drum shaft, high-temperature grease, and attaching hardware.

I replaced the drum shaft on the drum via the 4-screws accessed on the drum rear panel.

I removed the old bearing/bearing housing via the 2-screws holding it in place. I wasn't too concerned about loosing the small ball bearing as the kit provided me a new one. I generously applied some high-temperature grease to coat the interior lining of the new bearing housing. I also placed a dab on the back seat where the new ball bearing sits. This helped hold the bearing in place while reattaching it. I reinstalled the bearing housing to finish replacing the repair parts.

Reassembly of the drum is in the reverse order. I paid particular attention to making sure the new drum shaft properly seated with the new drum bearing housing.

After reinstalling the drum and while the front door panel was still off the dryer, it was easy to inspect the blower housing. I found the squirrel cage had broken loose from the molded nut that attaches it to the motor shaft. That would explain the heat problem; the heat was not being exhausted through the duct.

THE SQUIRREL CAGE IS REVERSE THREADED. I was unable to remove the nut from the motor shaft as the design encompasses a metal bushing molded into a plastic nut shaped form. The plastic would not hold up to the force I was applying trying to loosen the squirrel cage. So I ended up removing the entire motor and blower housing assembly from the base

The top panel was easily taken off by removing 2-screws from the back edge o ... Read more f the panel, and sliding it back to release it from the front panel seam.

The front panel is more involved, but still relatively easy for your average "do-it-yourselfer". I removed the front door panel by first removing the control panel (4-screws; 2 on top and 2 from the back of the panel). I removed 2 cable assemblies from the control panel via connecters (different sizes so didn't need to mark) and 2-wires attached to the large control panel mode selector (I marked these 2-wires). I set aside the control panel. I removed the front door panel by taking off 6-screws (2 on top, 2 on the bottom, and the remaining 2 on the inside of the panel on either side of the drum). After removing these 6-screws, I carefully pulled the front door panel away from the front of the dryer, carefully releasing 4-alignment latches (2 on either side). The front door panel was still electrically attached to the machine so I had to disconnect a couple more wires. I carefully disconnected 2-wires from the door light assembly and 3 more wires from the door switch (I marked the 3-wires on the door switch). I set aside the front door panel.

From the back of the dryer, I removed the small motor access panel on the bottom left corner. This panel also provides access to the drum belt. I released the drum belt from the motor drive wheel by releasing spring tension at the tensioner. The belt can easily be disconnected from the motor drive wheel and tensioner assemblies.

Removal of the drum was now possible. With the front door panel removed, the front of the drum is maintained in place via a small plastic stop on the top crossmember. I removed this stop prior to removing the drum. With one hand, carefully grabbing the belt that is was loosely draped across the back of the drum, and the other hand holding the front lip of the drum, I provided a quick and forceful upward motion to the back of the drum in order to dislodge the drum shaft from the bearing housing assembly. Once this was accomplished, I simple pulled the drum out of the dryer housing via the front of the machine.

The drum bearing repair kit ordered came with the replacement ball bearing, bearing housing, drum shaft, high-temperature grease, and attaching hardware.

I replaced the drum shaft on the drum via the 4-screws accessed on the drum rear panel.

I removed the old bearing/bearing housing via the 2-screws holding it in place. I wasn't too concerned about loosing the small ball bearing as the kit provided me a new one. I generously applied some high-temperature grease to coat the interior lining of the new bearing housing. I also placed a dab on the back seat where the new ball bearing sits. This helped hold the bearing in place while reattaching it. I reinstalled the bearing housing to finish replacing the repair parts.

Reassembly of the drum is in the reverse order. I paid particular attention to making sure the new drum shaft properly seated with the new drum bearing housing.

After reinstalling the drum and while the front door panel was still off the dryer, it was easy to inspect the blower housing. I found the squirrel cage had broken loose from the molded nut that attaches it to the motor shaft. That would explain the heat problem; the heat was not being exhausted through the duct.

THE SQUIRREL CAGE IS REVERSE THREADED. I was unable to remove the nut from the motor shaft as the design encompasses a metal bushing molded into a plastic nut shaped form. The plastic would not hold up to the force I was applying trying to loosen the squirrel cage. So I ended up removing the entire motor and blower housing assembly from the base

Read less

Was this instruction helpful to you?

Thank you for voting!

- Customer:

- Brian from Venice, FL

- Parts Used:

- 131264905

- Difficulty Level:

- Really Easy

- Total Repair Time:

- Less than 15 mins

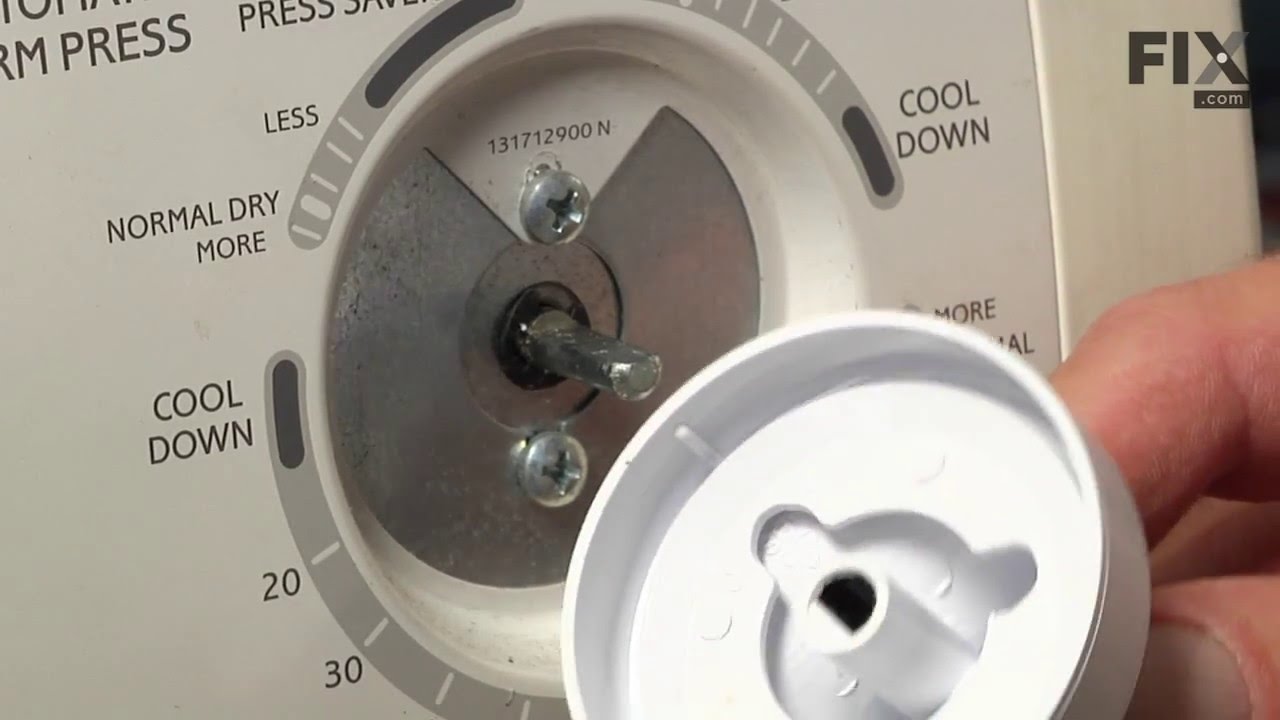

The knob was broken.

I positioned myself directly in front of the malfunctioning Frididaire dryer. Carefully griping the defective knob, I applied precisely the correct lateral pull to cause the offending appliance component to come away in my hand. Being ever mindful of the possibility of mixing up the two identical parts, old and new, and recognizing the po

... Read more

tentially catastrophic results of such carelessness, I segregated the old part from the new one by immediately placing it in a convenient waste basket. Having applied due diligence to the safe and proper disassembly process, I secured the new knob in my right hand, and being extremely careful to achieve correct alignment, I positioned the replacement in such a way as to require only a moderately firm push to slide the knob onto the switch shaft. Once the installation was complete, I tested the apparatus by turning the knob 360 degrees in a clockwise direction. Satisfied that all new components were functioning nominally, and that the planets of our solar system were still in synchronous orbit around the sun, I rewarded myself with a cold Miller Lite. Since any job worth doing, is worth doing right, I reflected upon the difficulties of the task I had just completed and reveled in a self-congratulatory moment. I hope my experience will serve as inspiration to others, and help them overcome the great challenges in their own lives.

Read less

Was this instruction helpful to you?

Thank you for voting!