Models

>

DDG7200LB

DDG7200LB General Electric Dryer

Jump to:

Find Part by Name

Keep searches simple, eg. "belt" or "pump".

Keep searches simple, eg. "belt" or "pump".

$31.09

This white idler pulley is used for many clothes dryers. A dryer's idler pulley wheel serves to help the belt to rotate the drum.

In Stock

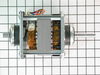

$349.53

Replaces "T" and "V" style motors. Includes two motor pulleys. If you have an older model dryer, the pulley may be pressed on or held on with a set screw. If pulley is pressed on, a new motor pulley must be ordered.

In Stock

In Stock

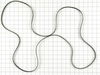

$24.28

This dryer drum belt has three ridges. The belt has been updated by the manufacture and is now thinner.

In Stock

Questions and Answers

We're sorry, but our Q&A experts are temporarily unavailable.

Please check back later if you still haven't found the answer you need.

Common Problems and Symptoms for DDG7200LB

Viewing 1 of 1Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

- Customer:

- Owen from Virginia Beach, VA

- Parts Used:

- WE17X10010, WE12X41

- Difficulty Level:

- Easy

- Total Repair Time:

- 1- 2 hours

- Tools:

- Pliers, Screw drivers, Socket set, Wrench (Adjustable)

Dryer made excessively loud noise when running.

I initially opened the front of the dryer and noticed that the drum slides that the drum rides on in the front of the dryer were excessively worn. I then removed the drum and noticed that the plastic bearing that supported the drum in the rear was cracked and the washer(?) appered to be disintigrating. I ordered and replaced the drum sl

... Read more

ides and rear bearing. The dryer was still making too much noise. I ran the motor with the drum removed and realized that they motor was the remaining source of the excessive noise. I then ordered and replaced the motor with a new one and this solved the problem. Total cost was around $140. Note that when ordering a new motor, the instructions on the web site indicate that you need to order the motor pulley if your existing motor has a pressed on pulley. The new motor was a kit that came with the pulley included, and therefore the additional part was not needed, and had to be returned. The instructional videos and parts schematics on the web site were very helpful.

Read less

Was this instruction helpful to you?

Thank you for voting!

- Customer:

- John from Grand Rapids, MI

- Parts Used:

- WE17X10010, WE12X41

- Difficulty Level:

- A Bit Difficult

- Total Repair Time:

- 1- 2 hours

- Tools:

- Nutdriver, Pliers, Screw drivers, Wrench set

main motor bearings frozen

Having recently replaced the heating elements and main bearing on the dryer I knew how to take the thing apart, getting to the motor was easy. However, the fan side of the shaft was longer than the original so I had to bend out the metal front panel where the fan is located so it would spin without grinding against the front of the dryer

... Read more

. That done, the rest was easy to finish, mounting bolts on the motor tightened, one last test before putting it back together and all was well. The dryer now works better than it has for a long time.

Read less

Was this instruction helpful to you?

Thank you for voting!

- Customer:

- Pauline from South Portland, ME

- Parts Used:

- WE17X10010, WE12X41

- Difficulty Level:

- Easy

- Total Repair Time:

- More than 2 hours

- Tools:

- Nutdriver, Screw drivers

Wouldn't start

Removed the front panel,tiped up the top panel ,removed the drum, drive belt,motor and exaust tube assembly. cleaned and vaccumed all lint from every were. Removed motor from fan blade and houseing. Reinstalled moter and pulley that came with the moter and fan blade. reinstalled all of the rest of the parts and plugedin the wires. once al

... Read more

l back together pluged into outlet and turned on and prasto works great.

Read less

Was this instruction helpful to you?

Thank you for voting!