Models

>

CGDS563SQ0

CGDS563SQ0 Crosley Dryer

Jump to:

Find Part by Name

Keep searches simple, eg. "belt" or "pump".

Diagrams for CGDS563SQ0

Viewing 4 of 4Manuals & Guides for CGDS563SQ0

Click to downloadKeep searches simple, eg. "belt" or "pump".

$19.63

The dryer thermal fuse, also sometimes referred to as the thermal cut off or temperature fuse, is a 2 by 1/2-inch, white, plastic safety mechanism that halts the flow of electricity to the motor circu...

In Stock

$17.19

This multi rib belt is an OEM replacement part for a dryer. It attaches to the drum, idler pulley, and motor pulley, and is responsible for spinning the drum. Over time, the belt can become frayed, br...

In Stock

$27.97

This thermostat is an OEM replacement part for a dryer. It is sold individually. It measures approximately 2-inches by 1.5-inches, is black and silver, and constructed of plastic and metal material. Y...

In Stock

$32.99

This OEM dryer door switch is an on/off mechanism that detects when the door is open to prevent the dryer from operating. If your dryer will turn on but will not start or continues working while the d...

In Stock

$30.89

This OEM kit comes with two ignition coils (one three-terminal boost/hold coil, and one two-terminal secondary coil). Usually only one of them burns out, but you should replace them as a set as both h...

In Stock

$37.48

This is an authentic drum support roller kit for 29-inch-wide dryers. It includes 1 belt, 2 roller wheels and an idler pulley. The parts in this kit allow the dryer to tumble properly by supporting th...

In Stock

$14.37

This is a rear drum support roller kit for your dryer. The 2 rollers come with 4 tri-rings, and 1 palnut. We recommend that you replace both rollers at once. This kit stabilizes the drum cylinder, whi...

In Stock

$17.64

The idler pulley is found in your dryer and provides tension to the belt in order to rotate the drum. If your clothes are taking a long time to dry, the machine is noisy while operating, or the dryer ...

In Stock

$40.54

This is a genuine OEM replacement igniter kit for your gas-heated clothes dryer. The silicon carbide igniter is used to light the gas that creates the heat in order to dry your clothes. If your dryer ...

In Stock

$13.42

This small but mighty OEM piece is called a tri-ring and is used to support the drum roller shaft and the idler pulley shaft in your dryer. It helps to provide a tight seal between components by evenl...

In Stock

$11.40

It is important for your dryer to be properly leveled, as an unleveled one can cause excessive vibration and noise when operating, may not drain properly, and can cause excessive wear on various parts...

In Stock

$47.91

This genuine OEM part is a radiant flame sensor for your gas dryer. It is used to determine when the temperature of the igniter is hot enough to ignite the gas. Once the igniter is hot enough, it allo...

In Stock

Questions and Answers

We're sorry, but our Q&A experts are temporarily unavailable.

Please check back later if you still haven't found the answer you need.

Common Problems and Symptoms for CGDS563SQ0

Viewing 12 of 12Noisy

Fixed by these parts

How to fix it

Too hot

Fixed by these parts

How to fix it

Drum Not Spinning

Fixed by these parts

How to fix it

Not Heating

Fixed by these parts

How to fix it

Marks left on clothes

Fixed by these parts

How to fix it

Door won’t close

Fixed by these parts

How to fix it

Won’t Start

Fixed by these parts

How to fix it

Heat stays on after drum has stopped

Fixed by these parts

How to fix it

Touchpad does not respond

Fixed by these parts

How to fix it

Running With Door Open

Fixed by these parts

How to fix it

Will Not Start

Fixed by these parts

How to fix it

Door Pops Open

Fixed by these parts

How to fix it

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

- Customer:

- ANTHONY from CHESHIRE, CT

- Parts Used:

- WP3392519

- Difficulty Level:

- Easy

- Total Repair Time:

- 15 - 30 mins

- Tools:

- Nutdriver, Pliers, Screw drivers

Dryer was working, but no heat.

First I unplugged the dryer, then removed the back panel, this exposed most all of the wiring and I could see the heater coils.

Not knowing what the problem was I started looking at the coils and could not see any broken parts.

So then checked the thermal fuse for continuity I removed the two wires from it with a small pair of ... Read more needle nose pliers, it was held in place by two screws, once they were removed the fuse came out easily, I checked continuity with a volt meter placing the meter on X1 Ohms and could not get a reading.

I replaced with a new one and put it all back together the way I took it apart.

Then I plugged it in and it worked first time, I now have warm dry clothes.

Not knowing what the problem was I started looking at the coils and could not see any broken parts.

So then checked the thermal fuse for continuity I removed the two wires from it with a small pair of ... Read more needle nose pliers, it was held in place by two screws, once they were removed the fuse came out easily, I checked continuity with a volt meter placing the meter on X1 Ohms and could not get a reading.

I replaced with a new one and put it all back together the way I took it apart.

Then I plugged it in and it worked first time, I now have warm dry clothes.

Read less

Was this instruction helpful to you?

Thank you for voting!

Dryer tub belt broke

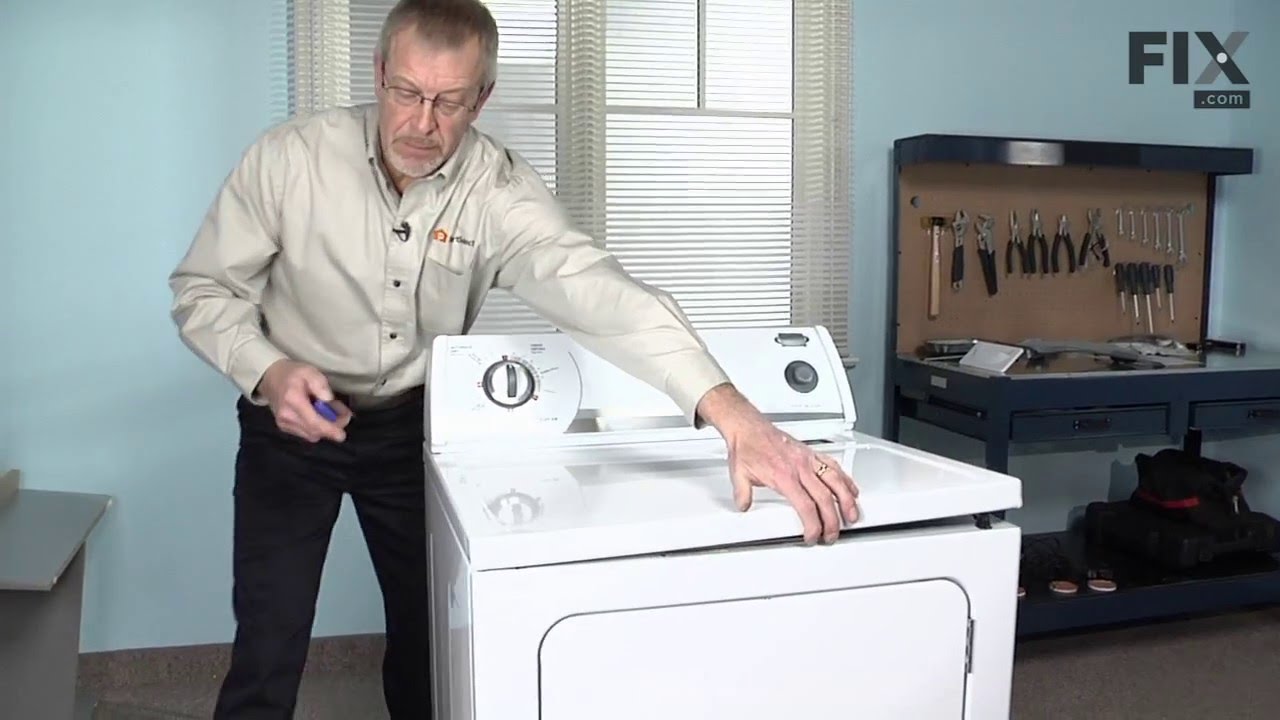

Removed the two screws that attatch the lent channel to the top of the dryer, then lifted the top of the dryer by pushing in on the two locking tabs located at the front , left and right , corners of the dryer top with a small flat head screw driver. The top of the dryer will fold back out of the way. At this point I removed the two 1/4 i

... Read more

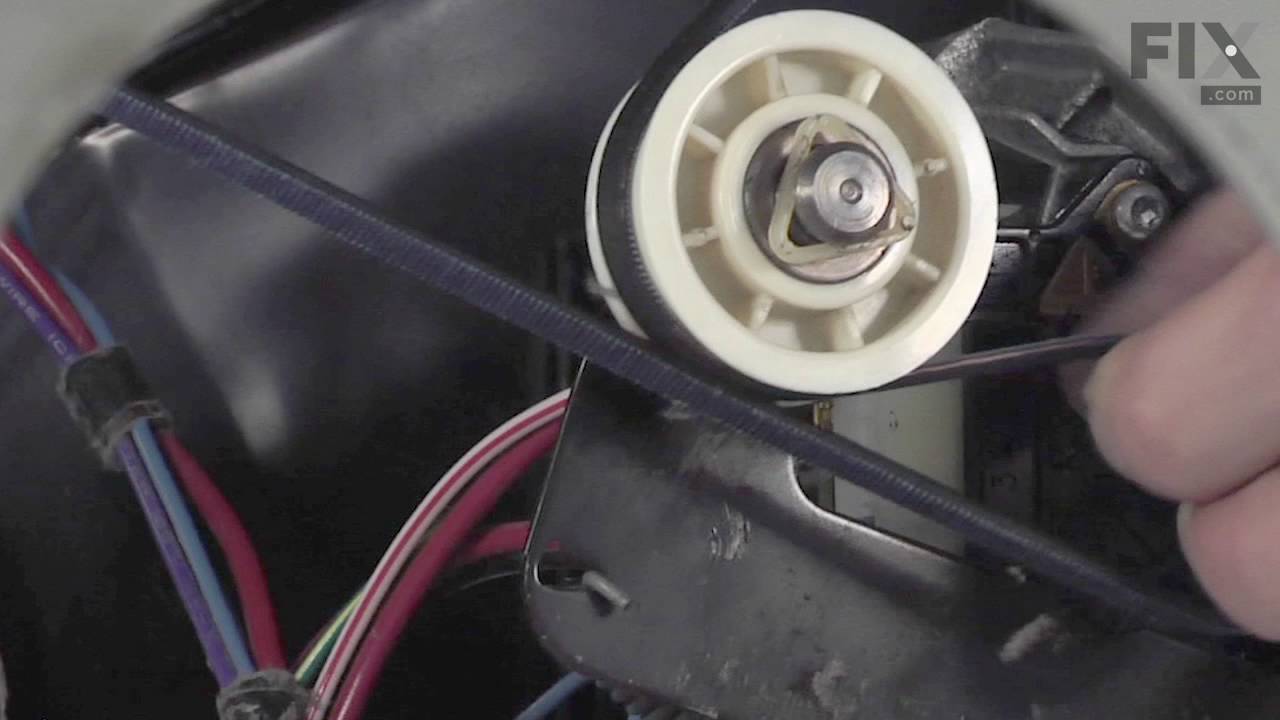

nch screws that are located on the inside of the dryer front left and right corners that hold the front panel/door to the two side panels. Now I was able to lift the front panel up and set it to the side. The bottom of the front panel that contains the dryer door that I just removed was held on the bottom by two clips that slide into slots on the front panel and did not require any removal to disconnect the bottom of the front panel, just pull up on the front panel. Since the tub was held in place by floating on a seal at the back of the dryer and a seal on the front panel , which I just removed the tub is now free floating except for the two alignment roller wheels at the bottom of the tub. It is easier if you lay the dryer on its back at this point with front of the tub pointing up. I pulled the tub out and cleaned the years of built up lent and removed all the pieces of the old , destroyed, belt. Note, the belt tentioner is located at the front of the motor which on the bottom right hand side. If your belt is broke like mine the tensioner may/will fall to the back of the dryer when you tilt it back, but do not worry. Once the dryer was cleaned up I put the tub back in place , still on its back and made sure the two alignment rollers were in place and rolled freely when the tub was turned by hand. Another note, my original belt tensioner did not have a rolling wheel that the belt rode on , but was a semi-circle smooth surface that the belt remained in constant friction with when the dyer was running, so I made sure the replacement tensioner I ordered with my new belt did have a rolling wheel that the belt would ride on, which I believe will reduce wear and extend the belt life. The new belt came with a diagram of the belt and tensioner routing which was helpful. Note: do not take the tensioner wheel off/apart when trying to route the belt. Follow the instructions routing diagram. The tensioner is held in palce by inserting the bottom back half into the slot in the bottom floor of the dryer making sure it is aligned with the belt pully on the shaft of the dryer motor. The dryer is still on its back side. Now, it was easier for me to route the belt around the center of the tub, following the marks from the original belt, and hold in in place in a few spots with masking tape and then route it thru the tensioner and onto the front pully of the motor. Make sure you have the grooves of the belt against the tub and the grooves are aligned with the pully on the motor. Now you can remove the masking tape that was holding the belt around the tub and spin the tub by hand watching the belt making sure it is not in a bind and is traveling around the motor pully , tensioner and tub freely. Make sure the tub is still sealed on the back side wall. As you turn the tub by hand you can adjust the belt by hand so that is following the original marks around the tub left by the orignal belt. Also double check the two alingment rollers and make sure they are spinning and on track. Now put the front panel with the door on by sliding it onto the two clips that are one the bottom at each side and put the two screws in that hold the front panel to the two side panels. Now stand the dryer back up and spin the tub by hand again making sure it has a good seal on the back side and on the front panel. Pull the top back down and put the two screws in that hold the lent channle to the top. I am not sure when the belt started failing on my dryer, but was amazed at how quiet it runs now. Guess I was use to the extra noise made by a dryer that was about to die. This was a cheap and easy repair and glad I did it myself.

Read less

Was this instruction helpful to you?

Thank you for voting!

- Customer:

- pat from lisbon,, OH

- Parts Used:

- WP3406107

- Difficulty Level:

- Really Easy

- Total Repair Time:

- 15 - 30 mins

- Tools:

- Screw drivers, Wrench set

door switch was bad

i was able to go on line with your company , find my dryer, order the part and had it the next day. fast , great , service

Was this instruction helpful to you?

Thank you for voting!