Models

>

AEM407W2

AEM407W2 (PAEM402W2) Amana Dryer

Jump to:

Find Part by Name

Keep searches simple, eg. "belt" or "pump".

Diagrams for AEM407W2

Viewing 18 of 18Keep searches simple, eg. "belt" or "pump".

$30.89

This OEM kit comes with two ignition coils (one three-terminal boost/hold coil, and one two-terminal secondary coil). Usually only one of them burns out, but you should replace them as a set as both h...

In Stock

$20.95

If your dryer is not tumbling, takes a long time to dry, or is noisy while tumbling, it may be time to replace the drum support rollers. These hold the drum in place while it rotates, so if they have ...

In Stock

$9.44

The multi rib belt, which may also be called a dryer drum belt or a multi-v belt, helps to rotate the drum of the dryer. The belt wraps completely around the drum, around a tension pulley, and then ar...

In Stock

$14.17

Located in the front bulkhead of your dryer are two drum glides, which help to ensure that the drum rotates smoothly and quietly while the dryer is operating. When the glides wear down, it can cause a...

In Stock

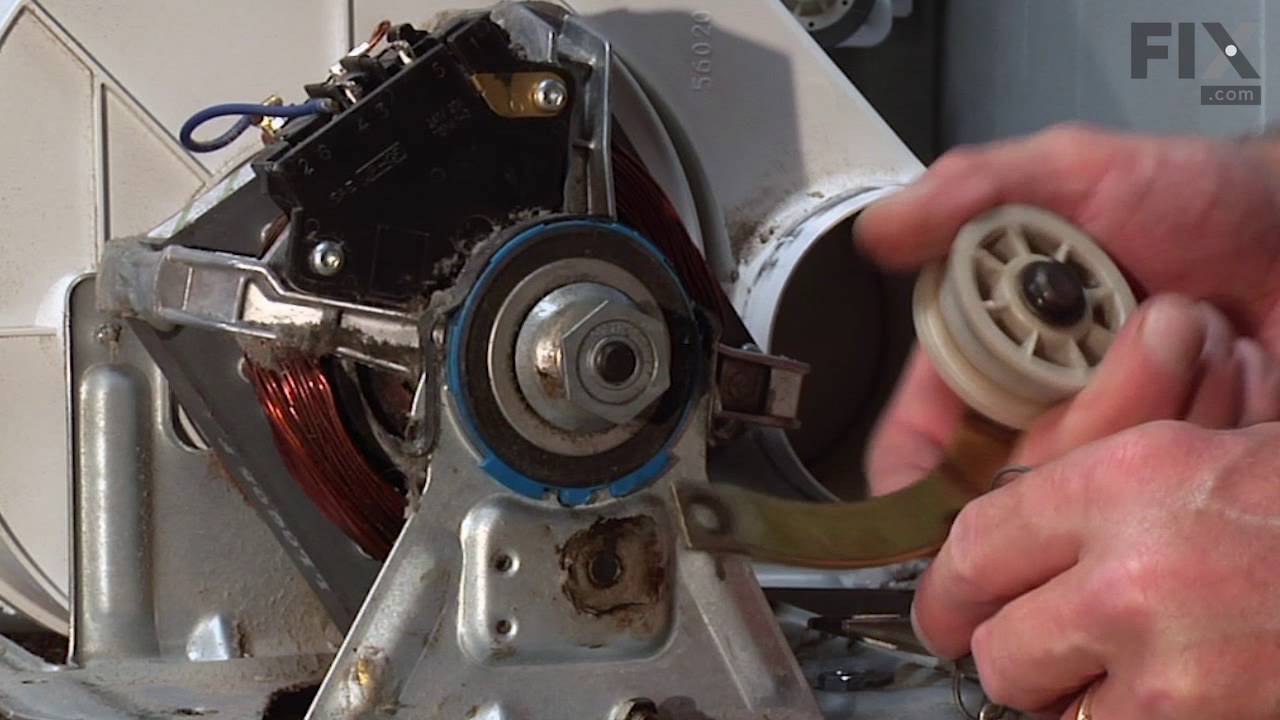

This two inch wide idler pulley wheel is beige in color and is made of plastic. This pulley wheel comes with its own metallic bearing in its center.

In Stock

In Stock

$12.97

Meant as a backup to a high limit thermostat, this fuse is typically set to trip at a higher temperature than that of a high limit thermostat. This is a one-time use fuse, so when it does trip, you do...

In Stock

$47.91

This genuine OEM part is a radiant flame sensor for your gas dryer. It is used to determine when the temperature of the igniter is hot enough to ignite the gas. Once the igniter is hot enough, it allo...

In Stock

In Stock

$35.69

The spring for this part is sold separately.

This idler assembly is for dryers.

Idler assembly includes the idler arm and the idler pulley that maintains tension on the drive belt, allowing the ...

In Stock

$13.58

This metal retaining ring is well under an inch long. Use it for your Maytag brand clothes washer or your clothes dryer.

In Stock

In Stock

Questions and Answers

We're sorry, but our Q&A experts are temporarily unavailable.

Please check back later if you still haven't found the answer you need.

Common Problems and Symptoms for AEM407W2

Viewing 9 of 9Noisy

Fixed by these parts

How to fix it

Door won’t close

Fixed by these parts

How to fix it

Too hot

Fixed by these parts

How to fix it

Marks left on clothes

Fixed by these parts

How to fix it

Not Heating

Fixed by these parts

How to fix it

Drum Not Spinning

Fixed by these parts

How to fix it

Will not agitate

Fixed by these parts

How to fix it

Burning smell

Fixed by these parts

How to fix it

Spins slowly

Fixed by these parts

How to fix it

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

- Customer:

- Chris from Hopedale, MA

- Parts Used:

- WP37001042, WP233520

- Difficulty Level:

- Easy

- Total Repair Time:

- 15 - 30 mins

- Tools:

- Pliers, Screw drivers

Drum not centered , clothes getting stuck in dryer

The first thing I did was to unplug the dryer from the wall. Then I removed the bottom two screws and slid the bottom cover off so i could see all the way to the back, I tipped the dryer back against the wall and searched for the problem with a flashlight. I noticed that one of the guide wheels that held the drum in place was sheared of

... Read more

f. I took the new drum support roller out and carefully slid it over the shaft, I had to jiggle it around for a bit, but then it finally was seated correctly. I replaced the washer and then the clip using a pair of needle nose pliers and a regular screw driver and then turned the dryer by hand to see if the wheel came off. After confirming that it worked, I put the cover back on, and plugged it in and tested it.

Read less

Was this instruction helpful to you?

Thank you for voting!

- Customer:

- Steven from Holderness, NH

- Parts Used:

- WP40113601, WP37001287, WP37001042, WP500121

- Difficulty Level:

- Easy

- Total Repair Time:

- 1- 2 hours

- Tools:

- Screw drivers, Socket set

Squeeling and grinding noise

Wasn't the belt!! Changed it anyway. Should have come here earlier. That mistake added several days to the repair waiting for a second batch of the right parts. Became a pro at taking the dryer apart and reassembling, though! Easy job, just take your time and mark your wires, if you need to.

Followed other people's excellent instru ... Read more ctions. Clean out all the dust bunnies. Schematics were a great resource. Those and the prices made me a repeat customer.

The shaft of the Idler Lever wheel was the cause, but decided, since I had it apart, to spend a little more money and replace both Drum Support Rollers and the Roller Bracket and Shaft Assembly. They showed some wear, and the parts were very inexpensive. Make sure you have snap ring pliers with prongs that are smaller than the standard 0.40 to save some aggravation with the Drum Rollers. $5 tool. Total parts were less than $60. Probably saved $150+ in labor. Quieter than ever now. Thanks!

Followed other people's excellent instru ... Read more ctions. Clean out all the dust bunnies. Schematics were a great resource. Those and the prices made me a repeat customer.

The shaft of the Idler Lever wheel was the cause, but decided, since I had it apart, to spend a little more money and replace both Drum Support Rollers and the Roller Bracket and Shaft Assembly. They showed some wear, and the parts were very inexpensive. Make sure you have snap ring pliers with prongs that are smaller than the standard 0.40 to save some aggravation with the Drum Rollers. $5 tool. Total parts were less than $60. Probably saved $150+ in labor. Quieter than ever now. Thanks!

Read less

Was this instruction helpful to you?

Thank you for voting!

- Customer:

- Michael from Kirkwood, MO

- Parts Used:

- 489P3, WP37001308, 279834, 279834, WP338906

- Difficulty Level:

- Easy

- Total Repair Time:

- 30 - 60 mins

- Tools:

- Nutdriver, Pliers, Screw drivers

Gas Dryer would not ignite

1. Removed lint screen and holder frame. Unplugged the electrical cord and closed the gas valve in the line before it goes into the dryer.

2. Removed two bolts at bottom front of machine and took off the bottom front panel.

3. Removed three bolts from black plastic exit vent and took it out to give more room to access everything ... Read more .

4. removed two wires and screws on the limit thermostat. Did the reverse to place the new one.

5. Removed wires (remembering placement), then holder screw. rotated the Gas Dryer Sensor counter clockwise to release the bottom tab so the sensor can be taken off the flame tube. Did the reverse to place the new one on.

6. Removed the one screw on the gas/flame tube that holds the bracket and igniter inside the flame tube. Removed the wires fro the igniter (remember placement) Slid the whole assembly toward the back of the machine to get the tube off the gas valve then rotated the whole assembly counter-clocwise to release the tab on the left side of the bracket. This was a little tight and had to work with it a bit to get the tab out and slide the whole piece out of the flame tube.

7. Once the tube and igniter were out i removed the scree that holds the igniter and replaced with the new one. Made sure no dust, etc. was in the piece.

8. Did the reverse to place the tube/igniter back into the flame tube.

9. Carefully and forcefully removed the wire connectors to the two coils. These were tough to get off. Removed the two screws that hold the bracket that holds the two coils in place. Slid the coils off the spindles remembering which one has the two wire connection and which one has the three wire connection and the way they went on. Replaced the old with the new. Placed the bracket onto the new coils and made sure the little bumps on the top are in the holes in the bracket. Tightened the screws to hold the coil bracket. Reattached the wire connectors to the coils making sure they go ALL the way back on.

10. Vaccumed everything I could to get lint, dust, etc. out.

11.Replaced the black vent plastic.

12 Made sure the exit vent on the back was not crimped or clogged. Checked the little flap door where the vent goes outside to make sure it opens and closes super easy to no air flow is restricted.

13. For testing I left the bottom panel open. Make sure you closed the door, reconnect the plug and turn the gas valve back on. Hit the go button on autodry or timed dry. The door must be closed to create the closed circulation of the system so the fan sucks the flame into the tube otherwise the flame will not fire deep into the tube and will set off one fo the overheat sensors. After hitting the go button your drum will start to rotate, then a few seconds later you'll hear a click and your igniter will start to burn bright orange. Another click and the gas should flow and ignite.

14. This shows that you've fixed the ignition problem. I just replaced everything I thought that could be wrong in stead of hunting and trial and error. All the parts were about $137 so I thought it was worth making sure.

15. IMPORTANT: If during your test the flame turns off after a little while then turns back on only to turn off again, don't panic. This happened to me as well. I found that you need to run the dryer with wet clothes in the dryer. The wetness in the clothes will keep the autodry sensor from shutting off the dryer since there will be moisture in the exhaust. If it's on timed dry the wet clothes will cool the exhaust air and keep the overheat sensors from turning the heat off. So no heating of dry clothes to get out wrinkles. Just dry the wet clothes. This is all I did and it's been working great so far. Good Luck!

2. Removed two bolts at bottom front of machine and took off the bottom front panel.

3. Removed three bolts from black plastic exit vent and took it out to give more room to access everything ... Read more .

4. removed two wires and screws on the limit thermostat. Did the reverse to place the new one.

5. Removed wires (remembering placement), then holder screw. rotated the Gas Dryer Sensor counter clockwise to release the bottom tab so the sensor can be taken off the flame tube. Did the reverse to place the new one on.

6. Removed the one screw on the gas/flame tube that holds the bracket and igniter inside the flame tube. Removed the wires fro the igniter (remember placement) Slid the whole assembly toward the back of the machine to get the tube off the gas valve then rotated the whole assembly counter-clocwise to release the tab on the left side of the bracket. This was a little tight and had to work with it a bit to get the tab out and slide the whole piece out of the flame tube.

7. Once the tube and igniter were out i removed the scree that holds the igniter and replaced with the new one. Made sure no dust, etc. was in the piece.

8. Did the reverse to place the tube/igniter back into the flame tube.

9. Carefully and forcefully removed the wire connectors to the two coils. These were tough to get off. Removed the two screws that hold the bracket that holds the two coils in place. Slid the coils off the spindles remembering which one has the two wire connection and which one has the three wire connection and the way they went on. Replaced the old with the new. Placed the bracket onto the new coils and made sure the little bumps on the top are in the holes in the bracket. Tightened the screws to hold the coil bracket. Reattached the wire connectors to the coils making sure they go ALL the way back on.

10. Vaccumed everything I could to get lint, dust, etc. out.

11.Replaced the black vent plastic.

12 Made sure the exit vent on the back was not crimped or clogged. Checked the little flap door where the vent goes outside to make sure it opens and closes super easy to no air flow is restricted.

13. For testing I left the bottom panel open. Make sure you closed the door, reconnect the plug and turn the gas valve back on. Hit the go button on autodry or timed dry. The door must be closed to create the closed circulation of the system so the fan sucks the flame into the tube otherwise the flame will not fire deep into the tube and will set off one fo the overheat sensors. After hitting the go button your drum will start to rotate, then a few seconds later you'll hear a click and your igniter will start to burn bright orange. Another click and the gas should flow and ignite.

14. This shows that you've fixed the ignition problem. I just replaced everything I thought that could be wrong in stead of hunting and trial and error. All the parts were about $137 so I thought it was worth making sure.

15. IMPORTANT: If during your test the flame turns off after a little while then turns back on only to turn off again, don't panic. This happened to me as well. I found that you need to run the dryer with wet clothes in the dryer. The wetness in the clothes will keep the autodry sensor from shutting off the dryer since there will be moisture in the exhaust. If it's on timed dry the wet clothes will cool the exhaust air and keep the overheat sensors from turning the heat off. So no heating of dry clothes to get out wrinkles. Just dry the wet clothes. This is all I did and it's been working great so far. Good Luck!

Read less

Was this instruction helpful to you?

Thank you for voting!