Models

>

2513

2513 Hoover Cooktop

Jump to:

Find Part by Name

Keep searches simple, eg. "belt" or "pump".

Diagrams for 2513

Viewing 3 of 3Keep searches simple, eg. "belt" or "pump".

This 6 inch surface burner with reinforced delta frame carries 1250 watts and 240 volts. It has four turns and is compatible with many electric ranges. Its center medallion is all black in color.

In Stock

$64.35

This trim ring is used with many electric ranges. It is a chrome trim ring that is intended for use with eight inch surface burner elements.

In Stock

$53.89

This trim ring is intended for use with many electric ranges. It is a chrome trim ring that is used with six inch surface burner elements. Notes The matching eight inch chrome trim ring is available w...

In Stock

$363.94

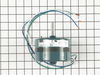

This part is used with down-draft models. It helps draw the steam and odors through the vent when the fan switch is activated.

In Stock

$92.66

This exhaust vent blower wheel is almost seven inches in diameter, and just under four inches deep. It is made entirely of metal and is used with a range's venting system.

In Stock

Special Order

Questions and Answers

We're sorry, but our Q&A experts are temporarily unavailable.

Please check back later if you still haven't found the answer you need.

Common Problems and Symptoms for 2513

Viewing 2 of 2Element will not heat

Fixed by these parts

How to fix it

Will Not Start

Fixed by these parts

How to fix it

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

- Customer:

- Richard from Beverly Hills, CA

- Parts Used:

- 715230K

- Difficulty Level:

- Easy

- Total Repair Time:

- 15 - 30 mins

- Tools:

- Pliers, Screw drivers, Wrench set

bad element control switch

1. Turn off power to range at circuit breaker

2. Remove grate

3 Remove control knobs

4, Remove two screws holding control panel

5. With wrench, remove locking nuts from control switches

6. Lift panel, exposing switches

7. With new switch in hand, unattach old switch one terminal at a time, attaching new swi ... Read more tch exactly as old switch, terminal by terminal.

8. Replace everything in reverse order

9.Turn on power

2. Remove grate

3 Remove control knobs

4, Remove two screws holding control panel

5. With wrench, remove locking nuts from control switches

6. Lift panel, exposing switches

7. With new switch in hand, unattach old switch one terminal at a time, attaching new swi ... Read more tch exactly as old switch, terminal by terminal.

8. Replace everything in reverse order

9.Turn on power

Read less

Was this instruction helpful to you?

Thank you for voting!

- Customer:

- Wade from CARMINE, TX

- Parts Used:

- 707704K

- Difficulty Level:

- Really Easy

- Total Repair Time:

- 1- 2 hours

- Tools:

- Nutdriver, Screw drivers

Motor bearing failure after 34 years.

Important: Down load the helpful assembly diagram for the fan motor and study it for a few minutes. It's very straight forward. Also a good idea is to remove the bottom panel which comes off easy before starting.

My only problem was removing the existing blower/fan wheel without damaging it once I had the assembly on the work b ... Read more ench. It was rusted on tight and managed to remove after a few tries using penetrating oil. The wheel is in stock and I'd suggest buying a new one along with the new motor if I had to do the job again.

Bottom line; the fan motor fit perfect but did have to re-use part of the old existing electric pig tail because the motor does not come with the factory type motor terminal connectors. By using three twist on wire connectors was back in business. The down draft vent works like new.

Wife is happy...

Wade

My only problem was removing the existing blower/fan wheel without damaging it once I had the assembly on the work b ... Read more ench. It was rusted on tight and managed to remove after a few tries using penetrating oil. The wheel is in stock and I'd suggest buying a new one along with the new motor if I had to do the job again.

Bottom line; the fan motor fit perfect but did have to re-use part of the old existing electric pig tail because the motor does not come with the factory type motor terminal connectors. By using three twist on wire connectors was back in business. The down draft vent works like new.

Wife is happy...

Wade

Read less

Was this instruction helpful to you?

Thank you for voting!

- Customer:

- Marjorie from Indianapolis, IN

- Parts Used:

- WPY04100165

- Difficulty Level:

- Really Easy

- Total Repair Time:

- Less than 15 mins

stove top burner would not heat

new element plugged into burner connection- an easy fix

Was this instruction helpful to you?

Thank you for voting!