Models

>

2175

2175 (Type 7) Poulan Chainsaw

Jump to:

Find Part by Name

Keep searches simple, eg. "belt" or "pump".

Diagrams for 2175

Viewing 3 of 3Keep searches simple, eg. "belt" or "pump".

$4.99

This fuel filter is for lawn and garden equipment engines.

Fuel filter cleans the fuel before it reaches the carburetor.

Work in a well-ventilated area when installing this part. Drain the fuel...

In Stock

$6.62

This chainsaw fuel line kit carries fuel from the tank into the carburetor and from the primer bulb to the fuel system. This part is mostly used on gas trimmers and blowers. The fuel lines are made fr...

In Stock

$6.21

This is a tank purge line, also known as a fuel line kit, and it is used with various lawn equipment. The line connects fuel from the tank into the carburetor, and from the primer bulb back into the f...

In Stock

$6.21

This part is the replacement fuel cap assembly for your chainsaw. It is made of black plastic and is sold individually. The fuel cap prevents fuel from spilling out of the chainsaw and prevents debris...

In Stock

$8.71

This is a single OEM purge bulb, also sometimes referred to as a primer bulb. It is usually located close to the starter rope. By pressing down on the purge bulb, this forces fuel into the fuel line f...

In Stock

$4.99

This is a foam air filter for small engines, used in various types of outdoor lawn and garden equipment. This genuinely sourced air filter is sold individually. This is a very important part to add to...

In Stock

In Stock

In Stock

In Stock

In Stock

In Stock

$7.46

This is a 3ft rope for a variety of power tools, most commonly chainsaws. It twists around the pulley of the recoil starter, which will allow you to pull-start the engine. This part is made of a durab...

In Stock

Questions and Answers

We're sorry, but our Q&A experts are temporarily unavailable.

Please check back later if you still haven't found the answer you need.

Common Problems and Symptoms for 2175

Viewing 2 of 2Will Not Start

Fixed by these parts

How to fix it

Engine stops after a few seconds or minutes

Fixed by these parts

How to fix it

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

Deterioration of fuel line system

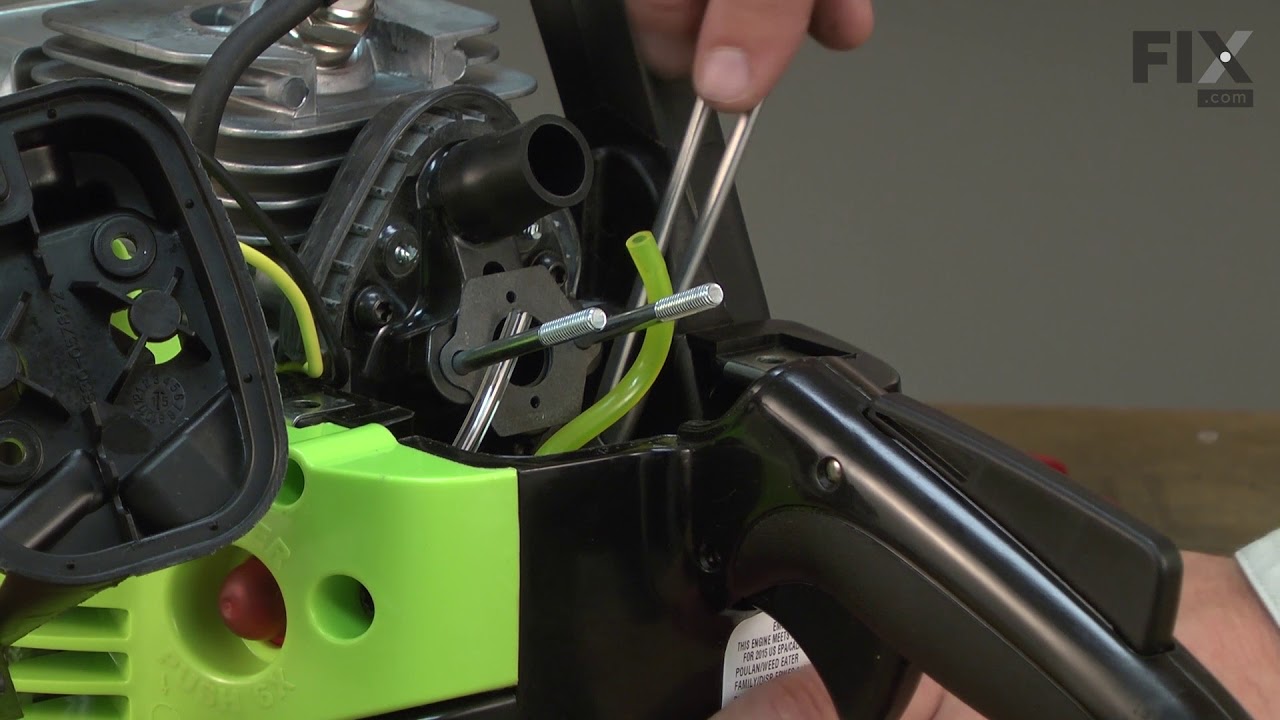

Removed the top cover (T25 torx), and side cover (T25 torx) with recoil starter. Drained all fuel, and removed all pieces of fuel old fuel line and the weighted filter from inside the tank by shaking out and the (long forceps). A spot headlamp makes it easier to see inside the tank for much of the procedure. Remove the foam filter to find

... Read more

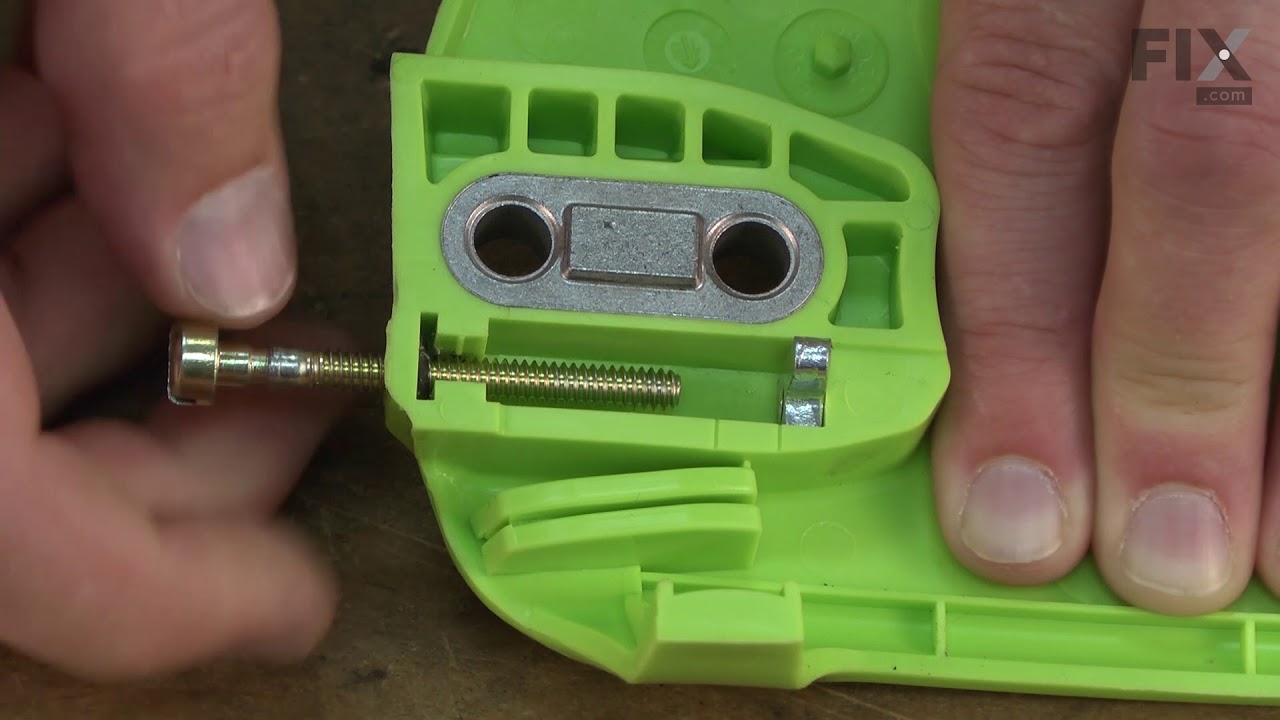

the two 8mm nuts and remove the air filter housing and carburetor (nut driver, 8mm socket) the choke lever slides out of its slot with some wiggling and moving the carb back off the mounting studs. Leave the throttle cable attached to the filter housing and move both assemblies out of the way to access the top wall of the fuel tank. There is a cover over the carb adjust screws that wiggles out also. The fuel line and purge line both pass through the wall of the tank and need to be pulled out with some effort (long curved forceps) from inside the tank through the fuel fill port. They are a tight fit. Pay attention to the lines size and location. Large line is in the position away from the recoil starter with the little plastic fitting hanging near the top of the tank. The smaller line is closest to the recoil starter. Both new lines will need to pass through the tank wall (this is the most difficult part). To facilitate the initial entry through the wall of the tank, cut a tapered end on your new lines. Use a very slippery lube to coat the end of the line and push it into the tank as far as you can from the top (forceps or soft grip pliers) help. Look inside the tank and pull the lines through fully out of the tank fill (long curved forceps and head spot light). Don't pull all the way through the fuel fill, just enough to install the new fuel line fitting in the return purge line and the new weighted filter on the fuel line and pull the lines back inside the tank. The return line with fitting close to the top of the tank and the filter hanging so it lays at the bottom of the tank, and able to swing around so it keeps contact with fuel at all times. Remove the old purge/primer bulb two screws (Phillips). The short stem is suction, long stem is pressure. Don't mix them up and connect lines backwards, don't ask me how I know! Lol! If you have such a saw like mine, that has no fuel lines intact, it is difficult to vision the line routes. There are helpful schematics on the internet. Just remember that the purge bulb long fuel stem sends pressure back to the tank through the return line (larger line in the tank with the line fitting away from the recoil). That line can now be cut to length and pushed on the bulb long stem. The suction side of the bulb short stem, connects to the purge line on the side of the carburetor (short line). You need to cut that line to the same length as the old one. It has to curve twice to get to the suction side of the purge bulb without kinking. The only other line left is the fuel line with the filter attached hanging inside the tank. Be sure you have the filter able to lay on the floor of the tank and move around. That line connects to the carburetor opposit side from the purge bulb. Dont cut that one until the carb is installed for proper length. The fuel routes from that filtered line into the carb, then out of the carb to the purge bulb suction side, then out to the return line in the tank with the fitting end. That fitting installed into the line serves only to keep the line from pulling back out of the tank, nothing attaches to it. Make sure all lines are clear of the mounting area of the carb, and throttle function. Pass the bulb lines through the slot in the side of the case being sure the lines don't kink. Secure the bulb with the two phillips screws. Position the carb on the studs and slide the choke lever into its place in the case as you go. Place the filter housing on the studs and push the carb and housing down watching the fuel lines for any kinks, especially where the throttle cable is in close proximity to the short carb purge line. Check the throttle function for interferance, and Install the two 8mm nuts. Now route the fuel line around the throttle mechanism out of the way, hold it to the barb on the side of the carb and cut it to length and install. Put some fuel mix in the tank (dont fill it) to test. Press the primer bulb, tilting the saw with fill cap removed, and see if anything leaks, also watch fuel flow back to the tank inside as you press the bulb. You should see fuel and air bubbles from the purge line. When all air bubbles are gone the system is purged. Install the new foam filter in the housing and then the top and side cases. I did not reinstall the cover of the carb adjust needle screws so I could adjust the fuel/ air mixture to run at peak performance. Hope this helps! The kit that I got was perfect and there are some useful instructions included. Thank you! Respectfully Mark

Read less

Was this instruction helpful to you?

Thank you for voting!

Both the Fuel line and the Engine fuel line, where dry rotted.

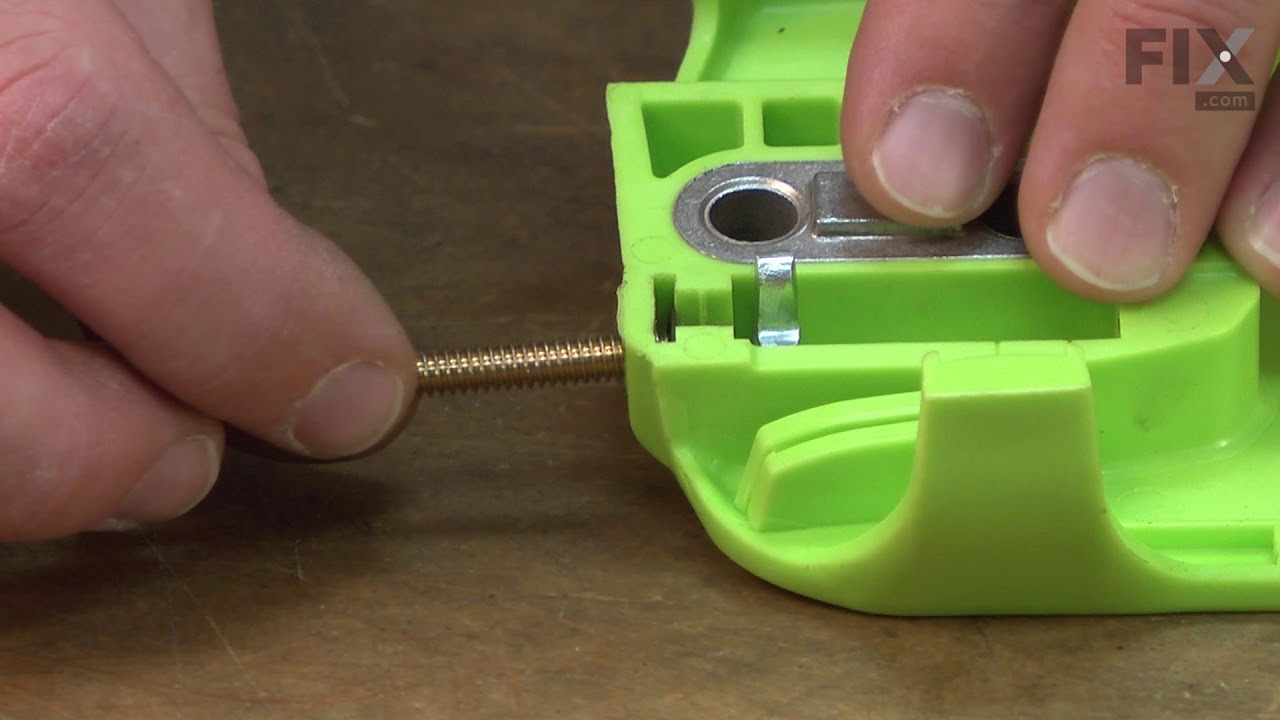

1) While still attached to the fuel tank, I first sized up the old fuel lines with the newer fuel lines.

2) With a pair of needle nose players, I then removed the old dry rotted fuel ?? lines, from the fuel tank.

3) I cleaned the fuel tank and around the carburetor area, to insure that there was no debris, that could possibly fa ... Read more ll into the path of the new fuel lines installation.

4) I then installed the smaller one of the fuel lines, so that it would be out of the way, of the larger fuel line. I Pulled the fuel line through the smaller hole in the fuel tank, with needle nose players. I pulled the smaller fuel line out through the fuel tank filler hole, attached the fuel filter to the smaller fuel line. I Made sure that the fuel filter was extended to the furthest end of the fuel tank bottom. Six inches in all. I then attached the smaller fuel line to the carburetor.

5) I Installed the larger fuel line, followed the same procedures as the smaller fuel line.

6) Both fuel lines where cut on an angle for easy installation. No lubricant was necessary.

7) I filled up the fuel tank with fresh fuel and oil, new air filter and spark plug. It started on the first pull. Amazing.

2) With a pair of needle nose players, I then removed the old dry rotted fuel ?? lines, from the fuel tank.

3) I cleaned the fuel tank and around the carburetor area, to insure that there was no debris, that could possibly fa ... Read more ll into the path of the new fuel lines installation.

4) I then installed the smaller one of the fuel lines, so that it would be out of the way, of the larger fuel line. I Pulled the fuel line through the smaller hole in the fuel tank, with needle nose players. I pulled the smaller fuel line out through the fuel tank filler hole, attached the fuel filter to the smaller fuel line. I Made sure that the fuel filter was extended to the furthest end of the fuel tank bottom. Six inches in all. I then attached the smaller fuel line to the carburetor.

5) I Installed the larger fuel line, followed the same procedures as the smaller fuel line.

6) Both fuel lines where cut on an angle for easy installation. No lubricant was necessary.

7) I filled up the fuel tank with fresh fuel and oil, new air filter and spark plug. It started on the first pull. Amazing.

Read less

Was this instruction helpful to you?

Thank you for voting!

Fuel and Purge lines had disintegrated

Disassembled it and cleaned fuel tank. Cut and ran new fuel lines, installed filter and reassembled. Parts fit perfectly and got running after not running for over 20 years.

Was this instruction helpful to you?

Thank you for voting!