Getting the Most from your Combination Square

A combination square is such a ubiquitous tool that many woodworkers take it for granted and do not get the most from it.

Let’s take a look at some of the more interesting uses for this tool.

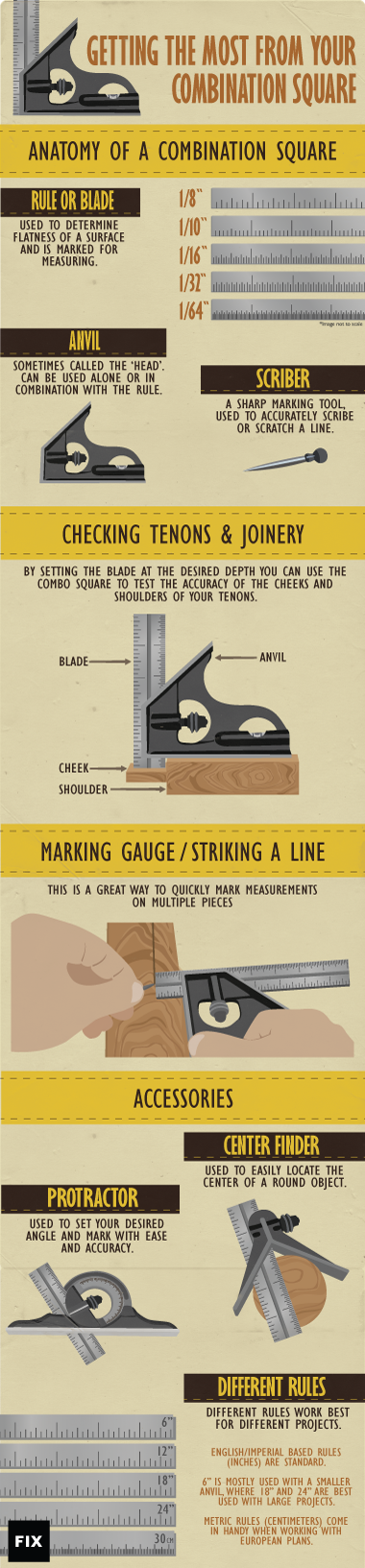

Anatomy of a Combination Square

The Rule or Blade

This straight edge is used to determine flatness of a surface.

Better-quality rules are hardened steel and accurately etched.

The Anvil

Sometimes called the "head", the anvil can

be used alone or in combination with the rule. The anvil

contains a draw bolt that secures the rule and is tightened via a

thumbscrew. This innovation is the primary driver of the combination

square’s popularity: it allowed the user to adjust the rule,

something you could not do with a traditional fixed-blade try square.

The Scriber

This sharp marking device is built into the anvil.

It is used to accurately scribe or scratch a line. This tool-within-a-tool

comes in handy in the field if you don’t have a marking knife, or need more

accuracy than a pencil can provide. The scratched-in scribe lines also have

the advantage of not smearing.

Common Uses

A combination square is most often used for striking a perpendicular line relative to the edge the anvil is touching,

and measuring short distances, but this barely scratches the surface of what this versatile tool can do.

In woodworking, the ability to do work faster and more efficiently is often crucial to success.

Historically, a bench carpenter would need several dedicated tools – try square, marking gauge, miter square,

level, etc. – to carry out the same jobs a single modern combination square is able to tackle with ease.

Let’s take a look at some of the ways a combo-square can help you de-clutter your workbench.

Determining Level

The built-in spirit level in the anvil can be used as a simple level.

When the bubble is centered between the two lines on the vial you know

the piece you are checking is level at that location.

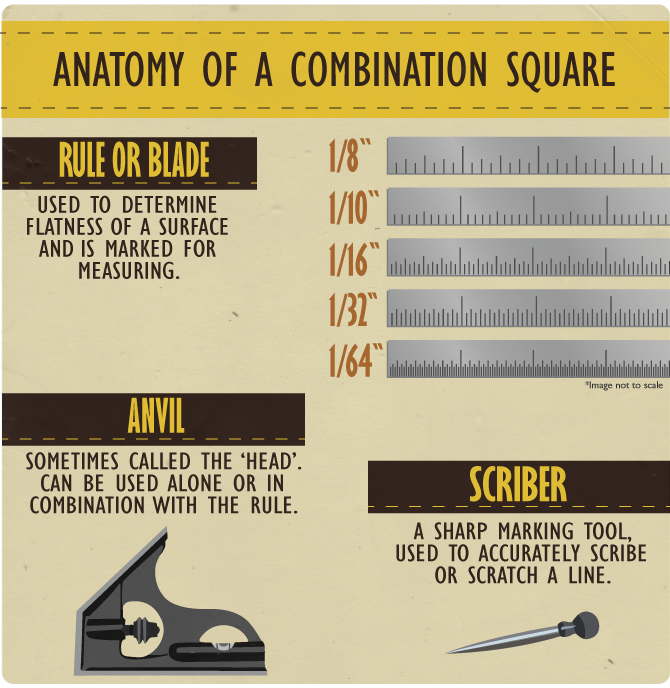

Checking Tenons and Similar Joinery

By setting the blade at the desired depth you can use the

combo square to test the accuracy of the cheeks and

shoulders of your tenons.

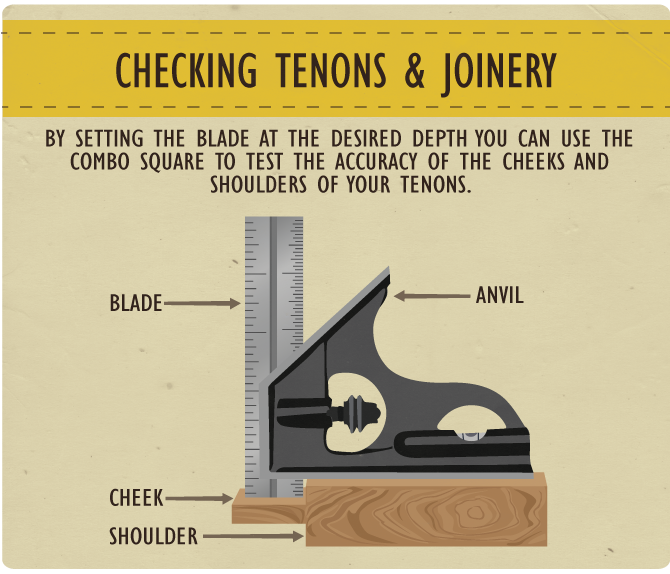

Marking Gauge/Striking a Line

When laying out joinery, it is often useful to strike

a line parallel to the edge of the piece you are working on. Normally this would

be accomplished with a dedicated marking gauge. You can achieve this by setting the

square to the desired offset and running the square down the side of the piece with

one hand while striking the line with the scriber or a marking knife pressed up

against the rule. This process is also a great way to quickly and accurately

transfer measurements to multiple work pieces.

Depth Gauge

When plowing a groove or cutting a mortise you’ll need to check the depth.

Similar to how we checked a tenon for square we can plunge the blade of a combo square

into a dado or mortise and check the depth. By moving the square around you can also

feel any high spots or crumbs that need to be removed.

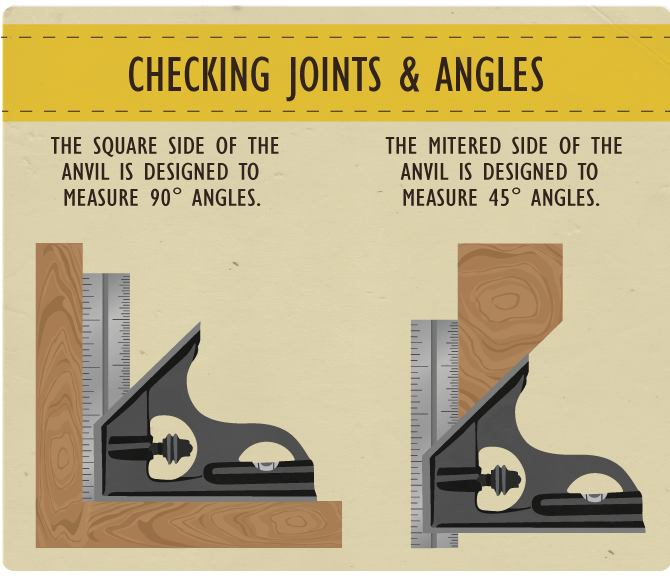

Checking for Square (Inside and Outside)

With the blade fully retracted you can also test inside and

outside corners of a piece for square. This comes in

handy when testing a cabinet carcass or frame.

Checking a 45-degree Miter

So far, we’ve spent most of our time

working with the squared off (90-degree) side of the anvil relative to the blade.

The other side of the anvil is machined to be 45 degrees. This common angle is used when testing

a 90-degree miter joint – each half of the joint is 45 degrees – and is often used in picture framing,

trim carpentry, and for many other similar jobs. Much as we tested a piece for square we can

test a piece for how accurate it is relative to 45 degrees. This relieves us

from needing a dedicated 45-degree miter square.

The above uses are pretty handy, but what do you do if your work is not all rectilinear?

There are some handy accessories that can augment what this tool can do.

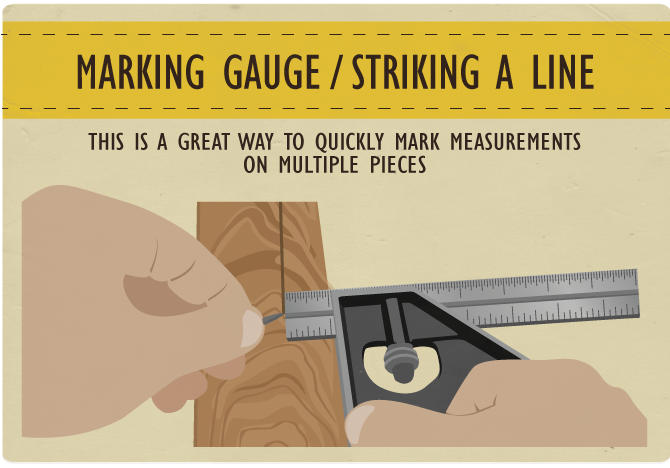

Accessories

Center Finder

The center finder attachment is great for finding the center of a round object.

You place the wood blank against this center-finding anvil and strike a line. Then rotate the

object and strike one or more additional lines. Where the lines all cross is the center. This

comes in handy when working at the lathe, where you want a quick way to find and mark the

center before mounting the piece onto the lathe.

Protractor

The protractor attachment allows you to

set the rule at any angle relative to the anvil face.

Thus, for complex layout tasks–like an eight-sided picture frame

or laying out a dovetail–you can set your desired angle and mark

with ease and accuracy.

Different Rules

The scale of your work also affects what type of

combination square will work best for you. If you do a lot of large-scale

work you’ll want to consider an 18"- or 24"-long rule. If you work with

a lot of European tools and plans you will want to seek out a metric rule.

If you work on smaller projects you will want a six-inch combination square

with a smaller anvil that can fit in an apron pocket.

Now that you’ve seen a lot of what this versatile tool can do,

you may want to go out and buy one. But where should you start?

Buyer’s Guide

- 1. Buy a machinist-quality square with a hardened blade, anvil, level, and scriber. You get what you pay for: skimping on this layout tool can lead to inaccuracies in your work

- 2. Make sure the blade size is appropriate for the scale of work you are going to be doing (see Different Rules, above)

- 3. Consider buying a set that includes some or all of the accessories you think you’ll need. If you cannot afford such a set,

buy from a reputable brand that is likely to still be around when you need to get accessories in the future

- 4. If you buy a used combination square you’ll want to check to

make sure it’s tuned and square. Strike a line, reverse the square,

and strike another in the same place. If the lines are not exactly on

top of each other, the square is out of true.

You can also refer to this

which talks more generally about making sure a square is actually square

When you invest in a quality combination square and using it to its full potential, your layout work, efficiency, and end results will all benefit.

Embed the article on your site