How to Fix an Inlet Hose or Screen for a Washer With Filling Issues

Water travels through the inlet hoses when it flows into your washer. There is a screen at the end of each hose, which catches debris from the water. If your washer has trouble filling up with water, your washer’s inlet hoses & screens may be clogged.

What are the Inlet Hoses & Screens?

The inlet hoses, or fill hoses, are approximately 5 feet long and are attached to the water inlet valves at the back of the appliance. The end of each hose has a screen which filters grit from the water, so it does not get into the tub. These screens are either plastic or metal.

Where are the Inlet Hoses & Screens?

The inlet hoses hook up your washer to your home’s main water supply.

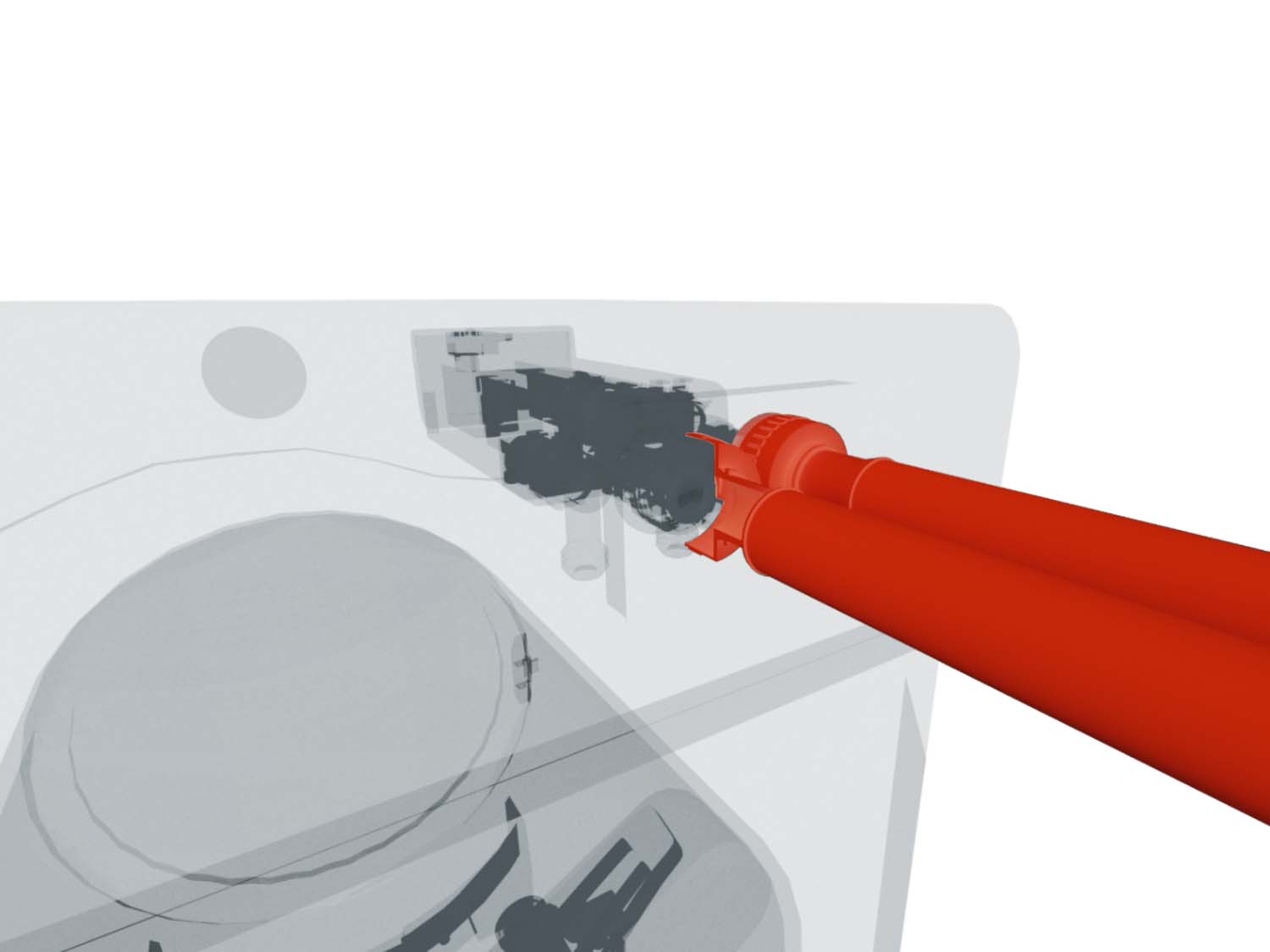

General Location of the Inlet Hoses & Screens in a Front Load Washer

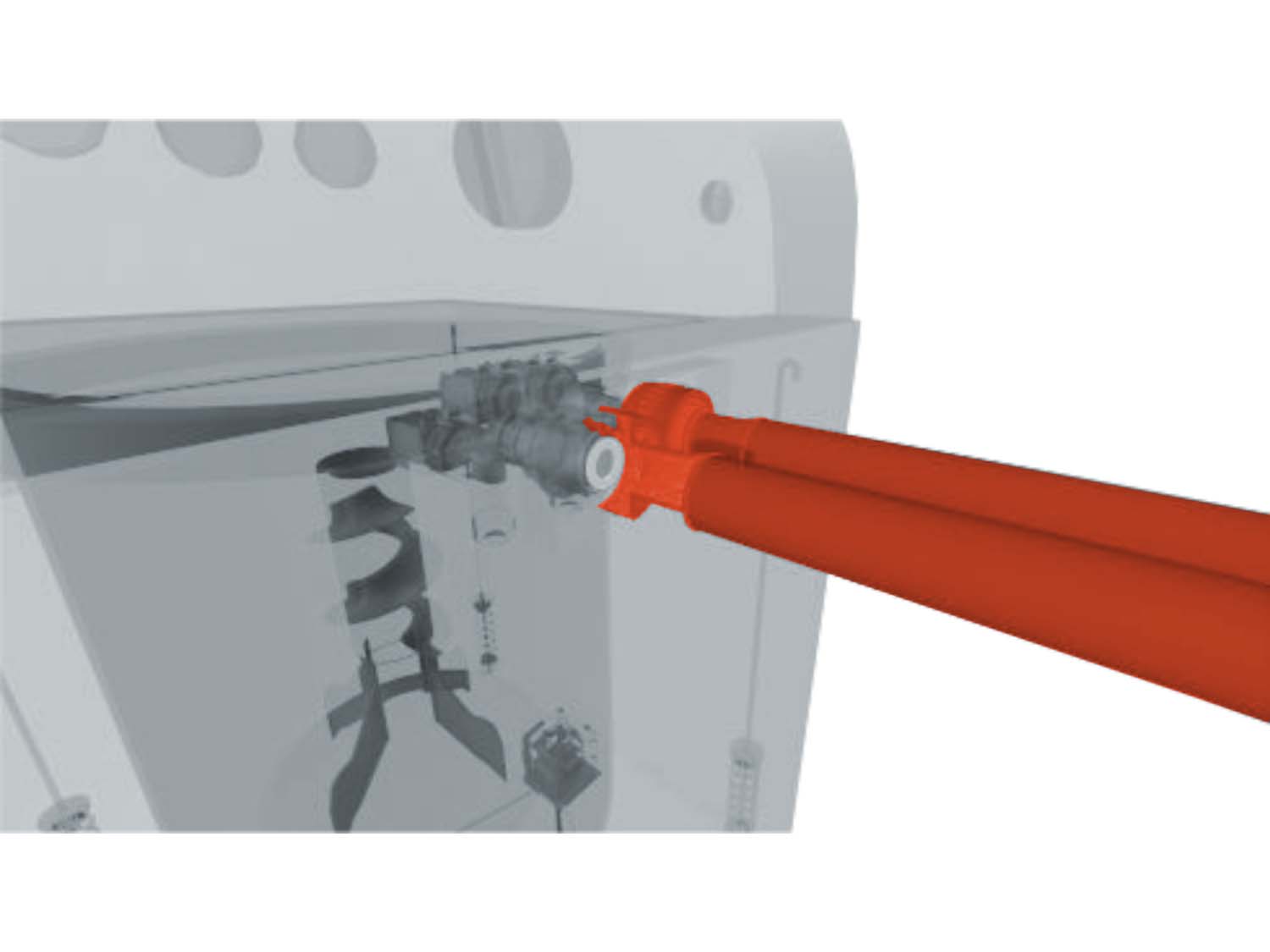

General Location of the Inlet Hoses & Screens in a Top Load Washer

What Different Types of Hoses are there?

Inlet hoses are made from rubber, reinforced rubber, hard plastic, or stainless steel. Rubber hoses can get pinched when they must make tight turns, leading to reduced water flow. They are also more susceptible to bursting. Braided stainless steel hoses have become the industry standard as they are stronger and more durable—some even have a built-in auto-shutoff feature that prevents flooding if the hose bursts. If your washer has rubber hoses, it is recommended that you opt for stainless steel hoses when replacing them.

How to Maintain the Inlet Hoses & Screens

You should regularly inspect the inlet hoses for kinks and damage and replace them every 3 to 5 years. Ensure there is at least 4 inches of space between the laundry room wall and the washer, to prevent the hose from bending too much. If the screens are plugged, they should be cleaned under hot water and with a small scrub brush. It is advisable to turn off the water supply when the washer isn’t in use to minimize the amount of pressure the hoses are under over time.

How to Access, Remove, and Inspect the Inlet Hoses & Screens

- As with all repairs, begin by unplugging your washer. If you have a gas washer, shut off the gas supply and disconnect the gas lines.

- Additionally, be sure to turn off your hot and cold water supplies.

- Shift your washer away from the laundry room wall.

- Place a towel underneath the hose connection to catch any water that leaks out.

- Loosen the metal fittings on the hoses, both at the back of the washer and at the faucets, with hose pliers.

- Locate the screens inside the valves and carefully pry them out using a flathead screwdriver.

- Inspect the hoses for corrosion.

- Inspect the screens. If they’re in good condition but are clogged, clean them with hot water and a small brush. Otherwise, replace them.

How to Install New Inlet Hoses & Screens

- Align the new screens to the valve openings and push the screens into place using needle-nose pliers.

- Connect the new hoses to the water supply valves by turning the metal fittings clockwise by hand and then tightening them further with hose pliers.

- Connect the new hoses to the inlet valves by turning the metal fittings clockwise by hand and then tightening them further with pliers. Be mindful that you are connecting the hot water hose to the hot water inlet and cold water hose to the cold inlet.

- Push the washer back into position.

Next: Troubleshooting the Water Inlet Valve

Go To Main Page: Water Filling Issues