Models

>

MAT23PCAAG

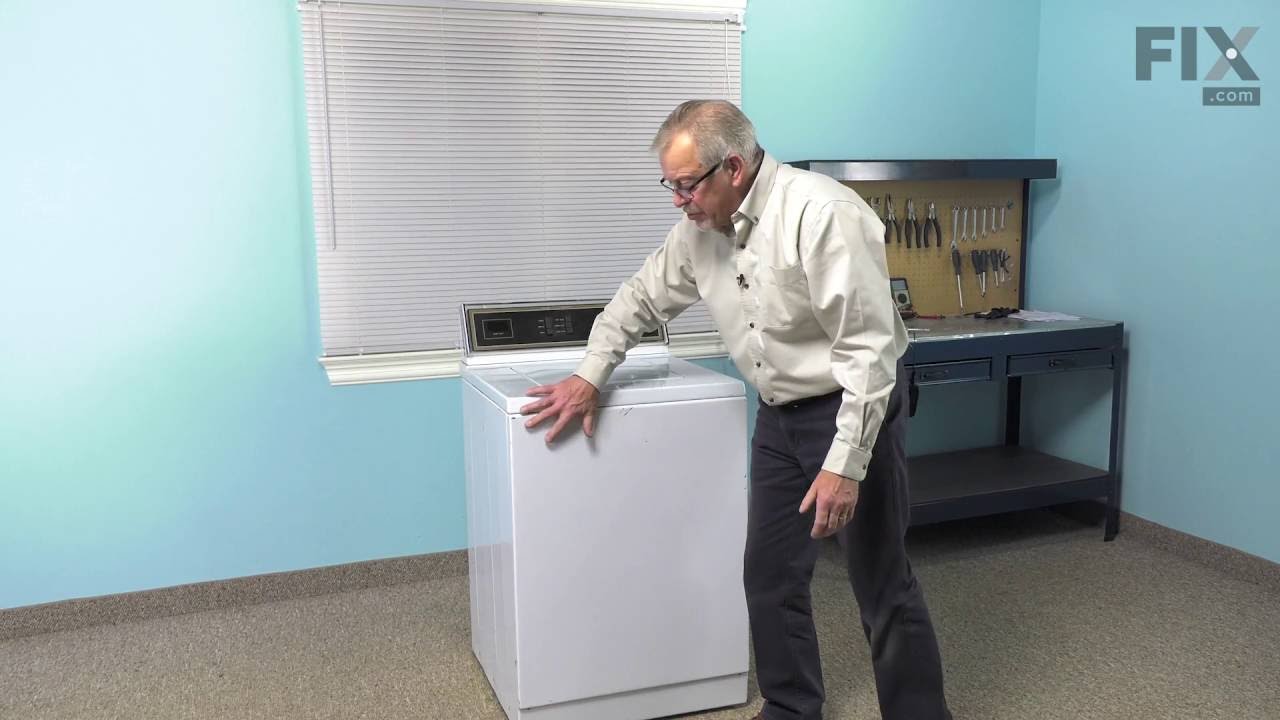

MAT23PCAAG Maytag Washer

Jump to:

Find Part by Name

Keep searches simple, eg. "belt" or "pump".

Diagrams for MAT23PCAAG

Viewing 9 of 9Keep searches simple, eg. "belt" or "pump".

$41.25

Over time, the belts in your washer can either stretch out and sag, or become brittle and snap. When this happens, it can result in the belt losing its grip and will not be able to spin or drain the t...

In Stock

Order within the next 3 hrs and your part ships today!

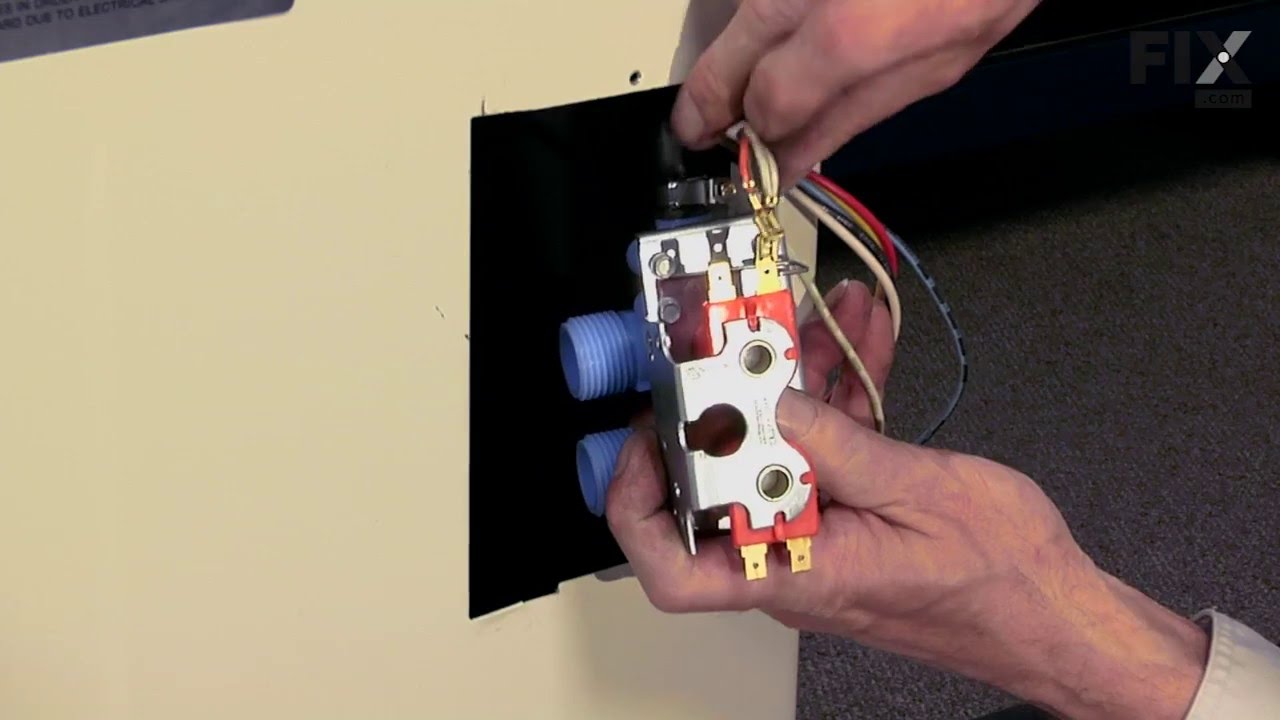

$98.44

This part has two ports for water to enter. It is blue and is intended for use with many washing machines and comes with a multi-mount bracket and an outlet adaptor.

In Stock

Order within the next 3 hrs and your part ships today!

$21.32

This part is commonly known to cause a leak at the top left corner of the outer tub. It fits over the injector nozzle.

In Stock

Order within the next 3 hrs and your part ships today!

$20.79

This is a screw and it is made for multiple appliances in your home. This model is called a sheet metal screw because it has sharp points, and the threads are closer together. This screw is designed t...

In Stock

Order within the next 3 hrs and your part ships today!

$23.69

This 3 prong lid switch is used for washing machines that do not have a tub light.

In Stock

Order within the next 3 hrs and your part ships today!

$10.35

This injector nozzle is just under three inches long. It is white in color and made entirely of plastic.

In Stock

Order within the next 3 hrs and your part ships today!

$5.42

This is a multi-use screw and can be used on a variety of appliances. The measurements of the screw are: 8/18 x 3/8. *Please note: the screw is sold individually. Refer to the manual provided by the m...

In Stock

Order within the next 3 hrs and your part ships today!

$11.80

This hose clamp extends from half an inch to an inch in diameter. It is made entirely of metal and is intended for use with Maytag brand washing machines.

In Stock

Order within the next 3 hrs and your part ships today!

$200.68

This washing machine drain pump is intended for use with automatic washers that have been manufactured since 1958. The pump itself is made of plastic, though it does come with a metallic belt pulley.

In Stock

Order within the next 3 hrs and your part ships today!

$15.28

This foot pad is just over an inch in diameter. It is made entirely of rubber and is gray in color. This pad is intended for use with washers and some dryers.

In Stock

Order within the next 3 hrs and your part ships today!

This washing machine lid hinge ball is well under an inch in diameter. These hinge balls are sold separately, though two are required per lid. This lid hinge ball is made of plastic and is used for Ma...

In Stock

Order within the next 3 hrs and your part ships today!

$18.47

Sold Individually. This adjustable leveling leg comes with a stop nut.

In Stock

Order within the next 3 hrs and your part ships today!

Questions and Answers

We're sorry, but our Q&A experts are temporarily unavailable.

Please check back later if you still haven't found the answer you need.

Common Problems and Symptoms for MAT23PCAAG

Viewing 14 of 14Leaking

Fixed by these parts

How to fix it

Burning smell

Fixed by these parts

How to fix it

Will not drain

Fixed by these parts

How to fix it

Will not agitate

Fixed by these parts

How to fix it

No hot or cold water

Fixed by these parts

How to fix it

Spins slowly

Fixed by these parts

How to fix it

Will Not Start

Fixed by these parts

How to fix it

Lid or door won’t close

Fixed by these parts

How to fix it

Spinning Issues

Fixed by these parts

How to fix it

Touchpad does not respond

Fixed by these parts

How to fix it

Noisy

Fixed by these parts

How to fix it

Shaking and Moving

Fixed by these parts

How to fix it

Won’t Start

Fixed by these parts

How to fix it

Water Filling Issues

Fixed by these parts

How to fix it

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

- Customer:

- Brian from El Cajon, CA

- Parts Used:

- 205613

- Difficulty Level:

- Really Easy

- Total Repair Time:

- Less than 15 mins

- Tools:

- Nutdriver, Wrench (Adjustable)

Cold water valve only opened to a trickle

I started by unplugging the appliance and then shut off the hot and cold water faucets then I disconnected and drained the hoses. Next, I removed the two screws that held the valve assembly in place. I then pulled the assembly out about 3 inches and disconnected the two wire plugs. The last step was to loosen the hose clamp on the outl

... Read more

et hose and pull off the outlet hose. I reversed the steps to install the new assembly and the total repair took about 10 minutes.

Read less

Was this instruction helpful to you?

Thank you for voting!

Drum would not drain and there was a banging noise when the drum spun

I removed the 2 phillips screws on the bottom of the front panel. Then checked around to find the belts were actually below the floor panel.

I pulled the washing machine away from the wall and tilted it bacwards and found the pump belt was off the pully and the drive belt was badly damaged. I replaced the 2 belts which took no tools ... Read more and about 3 minutes to accomplish then resecured the front panel, pushed back in place and leveled. Complete repair from diagnosis to back in operation took less than 15 minutes.

I pulled the washing machine away from the wall and tilted it bacwards and found the pump belt was off the pully and the drive belt was badly damaged. I replaced the 2 belts which took no tools ... Read more and about 3 minutes to accomplish then resecured the front panel, pushed back in place and leveled. Complete repair from diagnosis to back in operation took less than 15 minutes.

Read less

Was this instruction helpful to you?

Thank you for voting!

Front load washing machine leaking on floor while in fill mode.

Removed two screws at bottom of front panel and then removed front panel. Then removed two self-tapping bolts (one on each side) holding top panel in place and swung the panel up, out of the way, to expose top of tub and water injection components. Cut off one pinch clamp and loosened screw clamp holding two injector hoses to the inject

... Read more

or sleeve. Removed these water injector hoses from injector sleeve assembly which is mounted on top of left side panel upper flange. Replaced deteriorated rubber injector valve, nozzle and the sleeve for the injector (plastic housing containing the injector valve and nozzle). Also replaced deteriorated injector tube seal where injector tube elbow mounts to top of tub assembly. Reinstalled injector hoses with a replacement screw clamp to replace the one cut off. tightened the new clamp and the other, original, screw clamp and checked for leaks. This solved the leakage problem. Secured top panel and re-installed front panel. Hardest part of the task was determining where the leak emanated from but once found and parts ordered, it was a relative snap to fix.

Read less

Was this instruction helpful to you?

Thank you for voting!