Models

>

YMEDB855DC1

YMEDB855DC1 Maytag

Jump to:

Find Part by Name

Keep searches simple, eg. "belt" or "pump".

Diagrams for YMEDB855DC1

Viewing 6 of 6Keep searches simple, eg. "belt" or "pump".

$26.95

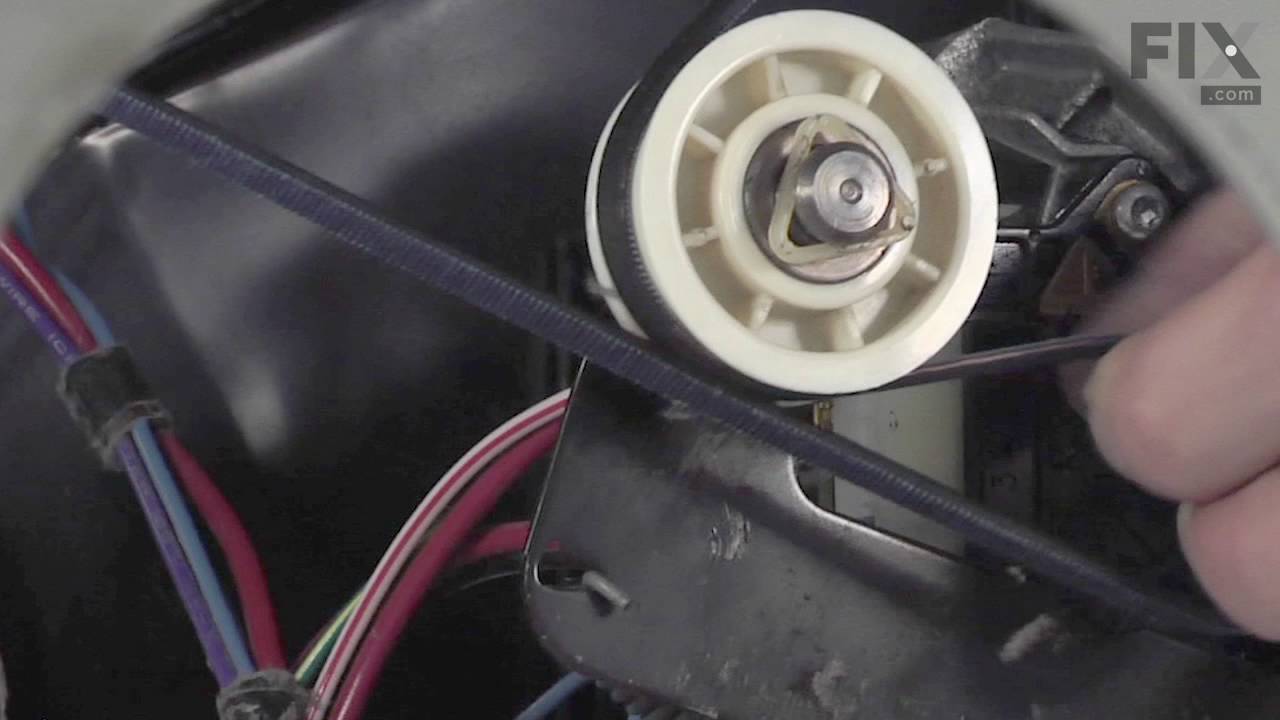

Often referred to as a dryer belt tension pulley wheel, this idler pulley is an OEM approved replacement part for a variety of dryer models. The idler pulley puts tension on the drive belt, and if the...

In Stock

$22.69

This drum support roller is sold individually. Most dryers require two. The tri-rings are included. This is a drum support roller for a dryer. It is a genuine replacement part. The part includes the d...

In Stock

$53.59

This dryer repair kit consists of five commonly replaced dryer parts: one multi-rib belt (part #661570V and measures 93 1/2 inches long), four drum support rollers, one idler assembly, nine tri-rings,...

In Stock

$13.42

This small but mighty OEM piece is called a tri-ring and is used to support the drum roller shaft and the idler pulley shaft in your dryer. It helps to provide a tight seal between components by evenl...

In Stock

$47.74

The internal-bias thermostat, also know as a thermistor, is used to prevent the dryer from overheating. It does this by monitoring and controlling the temperature of the inside of the dryer drum. If ...

In Stock

$11.40

It is important for your dryer to be properly leveled, as an unleveled one can cause excessive vibration and noise when operating, may not drain properly, and can cause excessive wear on various parts...

In Stock

This thermal cut-off kit includes a genuine OEM replacement high limit thermostat and a fuse. The thermostat is a safety device used to prevent the dryer from overheating, and the fuse serves as a bac...

In Stock

$26.79

If your dryer is not tumbling, will not start, or is excessively noisy while operating, there may be an issue with your idler pulley. The idler pulley works by maintaining a constant tension on the dr...

In Stock

This heating element connection wire kit is a genuine OEM replacement for your electric dryer. The kit is used to connect the thermostat to the heater element. The kit comes with a yellow wire nut and...

In Stock

$5.42

This is a multi-use screw and can be used on a variety of appliances. The measurements of the screw are: 8/18 x 3/8. *Please note: the screw is sold individually. Refer to the manual provided by the m...

In Stock

$7.95

This is a multi-use screw mostly used in dryers. It has a diameter of #10, length of one inch, and thread size of 16. Remember to follow safety practices and instructions provided in the manufacturer ...

In Stock

$7.95

This is a multi-use cover screw. It fits appliances such as dryers, ranges, washers, dishwashers, refrigerators, air conditioners, washer dryer combos, freezers, wall ovens, microwaves, dehumidifiers,...

In Stock

Questions and Answers

We're sorry, but our Q&A experts are temporarily unavailable.

Please check back later if you still haven't found the answer you need.

Common Problems and Symptoms for YMEDB855DC1

Viewing 10 of 10Noisy

Fixed by these parts

How to fix it

Too hot

Fixed by these parts

How to fix it

Door won’t close

Fixed by these parts

How to fix it

Not Heating

Fixed by these parts

How to fix it

Drum Not Spinning

Fixed by these parts

How to fix it

Leaking

Fixed by these parts

How to fix it

Touchpad does not respond

Fixed by these parts

How to fix it

Door Pops Open

Fixed by these parts

How to fix it

Won’t Start

Fixed by these parts

How to fix it

Marks left on clothes

Fixed by these parts

How to fix it

Keep searches simple. Use keywords, e.g. "leaking", "pump", "broken" or "fit".

- Customer:

- jason from HOLDEN, MA

- Parts Used:

- 4392067

- Difficulty Level:

- Really Easy

- Total Repair Time:

- 30 - 60 mins

- Tools:

- Socket set

very loud squeeling sound

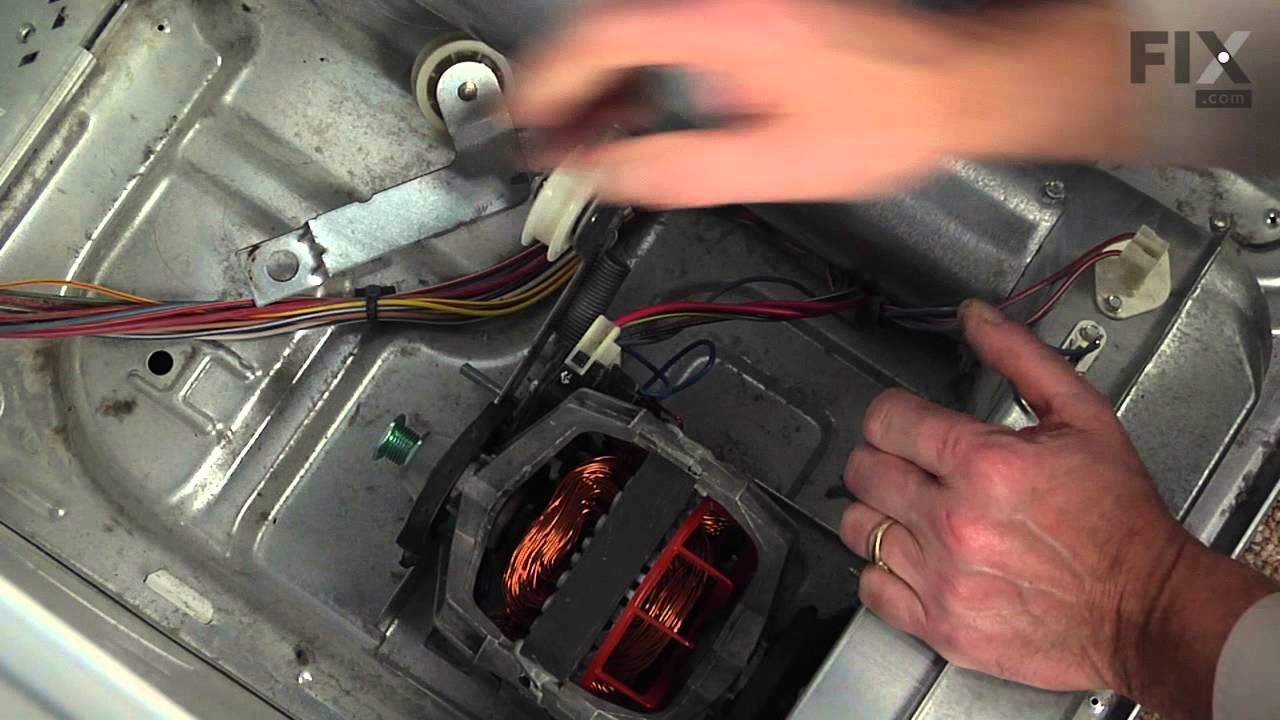

The issue was the idler pulley. First I began opening up the front panel based on a youtube video but soon realized the model was slightly different and required a lot more items to remove. I saw the pulley in the back with nothing in the way so I put the front panel crap back on and removed the rear panel. There it was, very simple to re

... Read more

move and replace. I'm not looking forward to drum rollers though. Hopefully they're aren't as difficult as they appear.

Read less

Was this instruction helpful to you?

Thank you for voting!

- Customer:

- GREGORY from Wilsonville, OR

- Parts Used:

- 279640

- Difficulty Level:

- Easy

- Total Repair Time:

- 15 - 30 mins

- Tools:

- Nutdriver, Pliers, Screw drivers

Very Loud Squeaking Noise

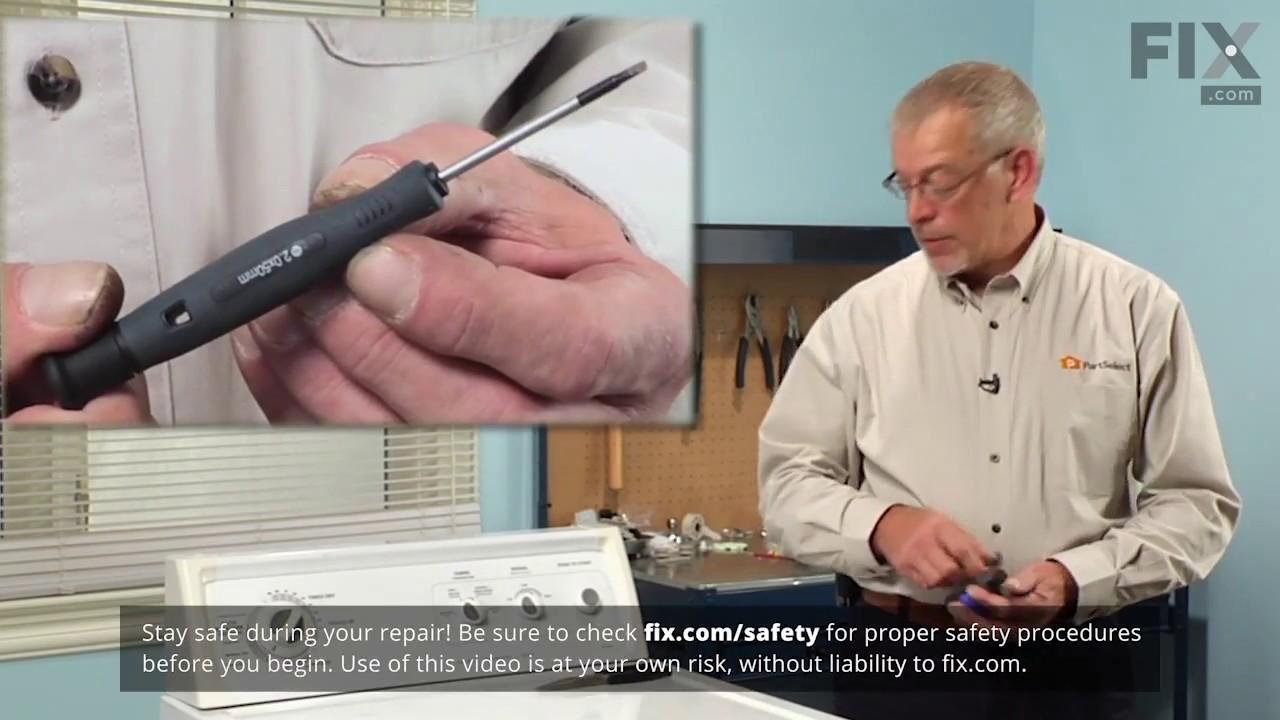

1) Disconnected power cord from wall. 2) Disconnected vent hose from back of dryer. 3)Removed dryer rear panel. 4)Disengaged tension spring on idle wheel arm. 5) Removed worn idle wheel. 6)Installed new Idler wheel assembly. 7) Vacuumed dust from rear of dryer (optional, recommended). 8) Reinstalled rear cover, vent hose and power cord. E

... Read more

asy repair 15-30

Read less

Was this instruction helpful to you?

Thank you for voting!

- Customer:

- Eddie from PELZER, SC

- Parts Used:

- 4392067

- Difficulty Level:

- A Bit Difficult

- Total Repair Time:

- More than 2 hours

- Tools:

- Nutdriver, Screw drivers

Squeaky Dryer Noise

I purchased the dryer repair kit with the drum belt, wheels and idler pulley. I watched the instructional videos online and it seemed fairly straight forward. Breaking down the dryer and replacing the pulleys was easy enough. My problem began when I tried to feed the drum belt around the idler pulley. After finishing the job, the dryer wo

... Read more

uld not turn and the sensor light stayed on. I thought something else was broken with the dryer and spent hours trouble shooting other problems that I was having. Finally I figured out that the drum belt was not installed correctly around the idler pulley. However, I could not get it properly installed from the front of the machine so I tried from the rear still with no avail. I finally had to fish the old belt out of the garbage can that I had thrown away earlier. I lined up the old belt with the new one in the kit and discovered that the new belt was much smaller, so I put the old one back on the drum. Here's the lesson I learned...make sure the belts are the same size before attempting to install. The old idler was responsible for the squeaking and that stopped but I am still using the same old drum belt. Hope it lasts.

Read less

Was this instruction helpful to you?

Thank you for voting!